Edge curling and bottom sealing device of combined firework outer cylinder

A combination of fireworks and crimping technology, which is applied in the direction of pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of low production efficiency of fireworks outer cylinders and cannot meet the needs of actual production, etc., and achieve efficient and reliable crimping and back-sealing processing and avoiding mechanisms Redundancy and efficiency-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

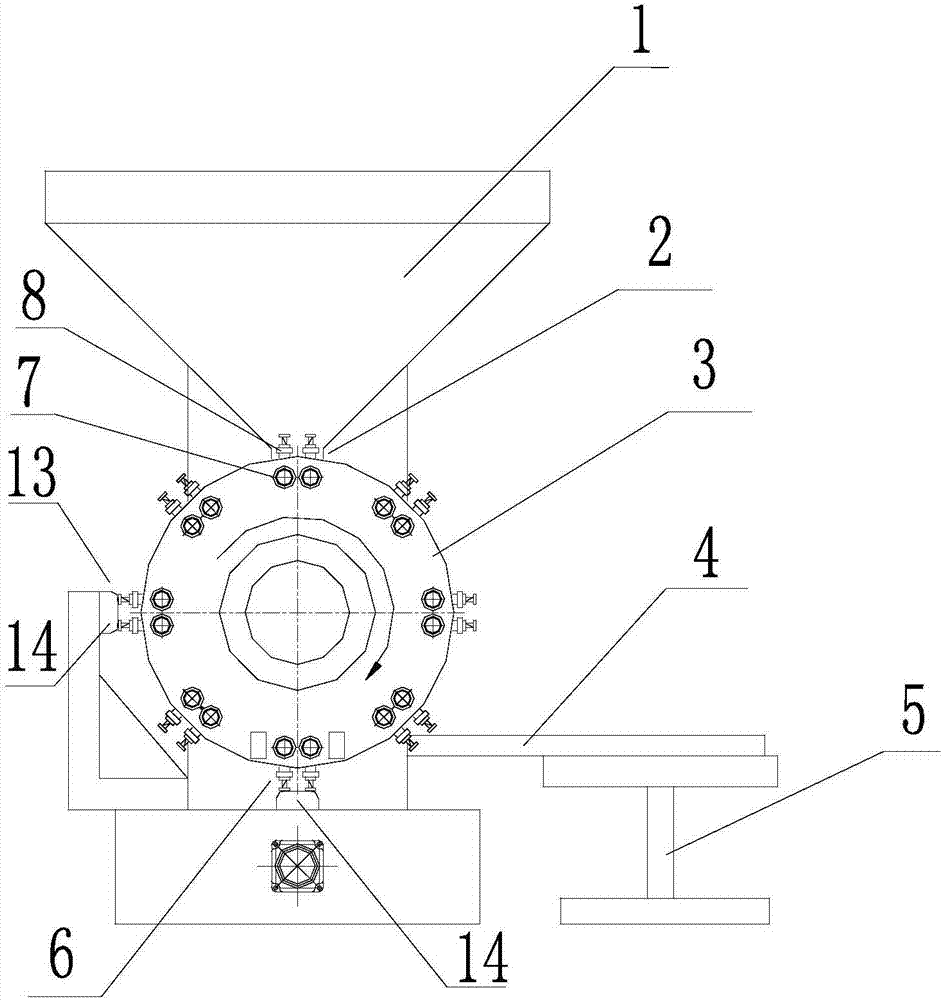

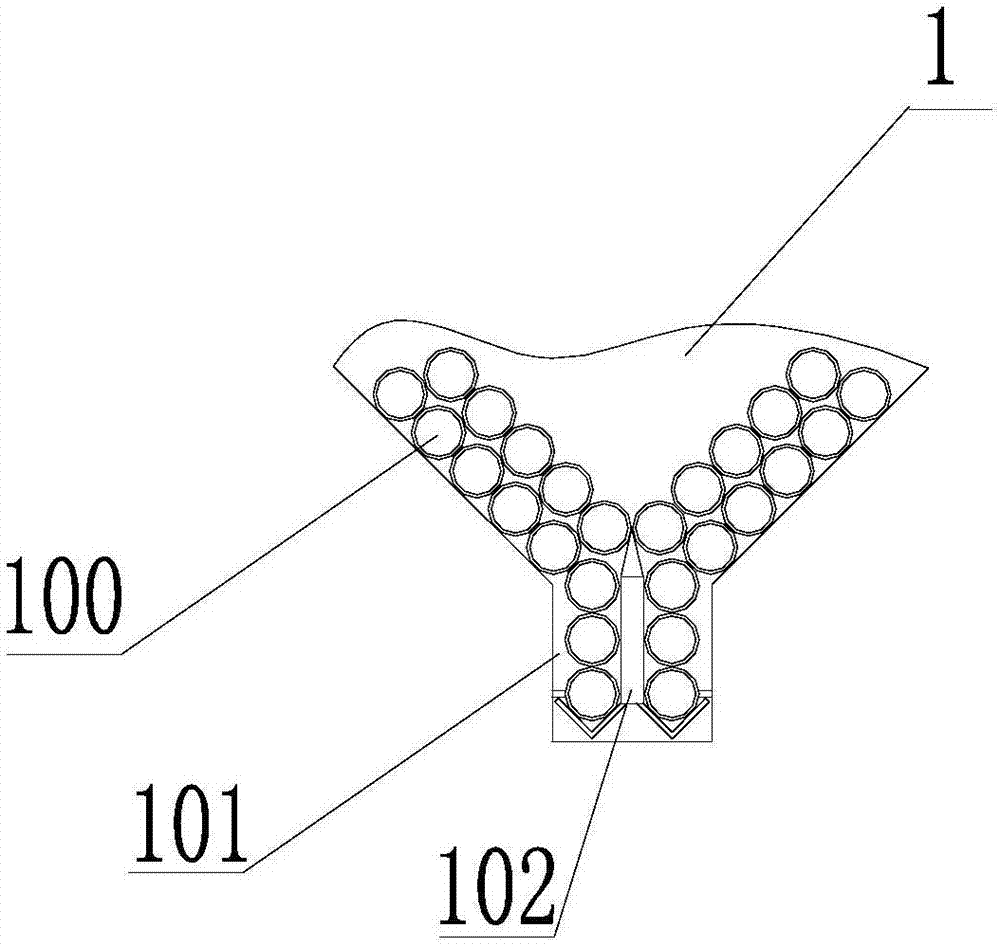

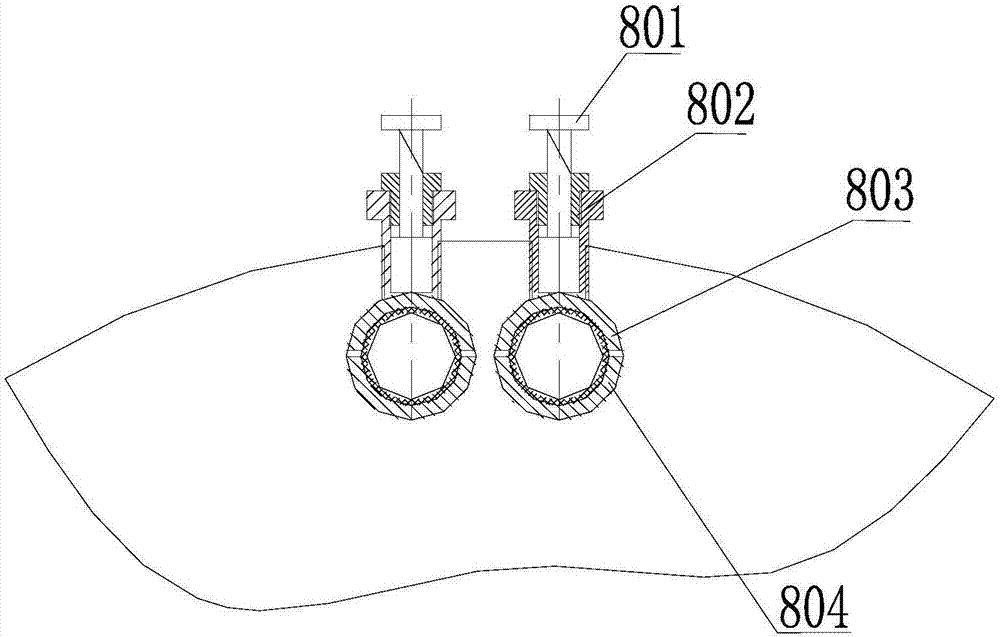

[0025] Embodiment 1: see Figure 1-7 , reflecting a specific structure of the present invention, the crimping and bottom sealing device of the combined fireworks outer cylinder includes a turntable 3 driven by a motor 303, a transmission 302, and a rotating shaft 301 to rotate intermittently, and eight positioning positions are evenly distributed along the circumference of the turntable 3. mechanism. Adapt to the working characteristics of the positioning cavity turntable system to achieve both efficiency and operational stability and reduce noise. Each positioning mechanism includes two cylinder positioning cylinder cavities 7 loaded with fireworks outer cylinders 100 arranged side by side. The feeding port 101 of the feeding hopper 1 is provided with a distribution member 102 . It is beneficial to improve the processing rate and the operation coordination of the positioning cavity turntable system.

[0026] During the rotation of the positioning mechanism with the turntab...

Embodiment 2

[0034] Example 2: see Figure 8 , the difference from Embodiment 1 is that the cylinder positioning cavities evenly distributed along the circumference of the turntable 404 adopt positioning grooves 410 .

[0035] It is no longer necessary to install a pusher at the blanking station 403, the notch of the positioning groove 410 corresponds to the discharge port of the discharge hopper 401, and the fireworks outer cylinder 402 at the discharge port corresponds directly to the radial direction of the cylinder according to gravity. Falling into the positioning groove cavity 410. A material roller 408 may be provided at the discharge opening of the discharge hopper 401 to help the fireworks outer cylinder 402 fall smoothly into the groove.

[0036] At the overlapping station 407 for crimping and pre-installation of paper bars, and the reinstallation station 406 for paper bars, a notch cover plate 405 is provided corresponding to the positioning groove cavity 410 to prevent the fire...

Embodiment 3

[0040] Embodiment 3: see Figure 9 , The barrel positioning cavity adopts a positioning groove cavity. The difference from Embodiment 2 is that the turntable adopts a fence structure, and the gaps between the railings form positioning grooves. For example, the gap 80e between the railing 90c and the railing 90b constitutes a positioning groove; or, the gap 80f between the railing 90a and the railing 90b constitutes a positioning groove. Firework paper tubes are clamped in the gaps 80e, 80f, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com