Supercritical carbon dioxide rock core fracturing experiment method under saturated pore pressure

A technology of carbon dioxide and experimental methods, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of lack and limit the application range of carbon dioxide, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

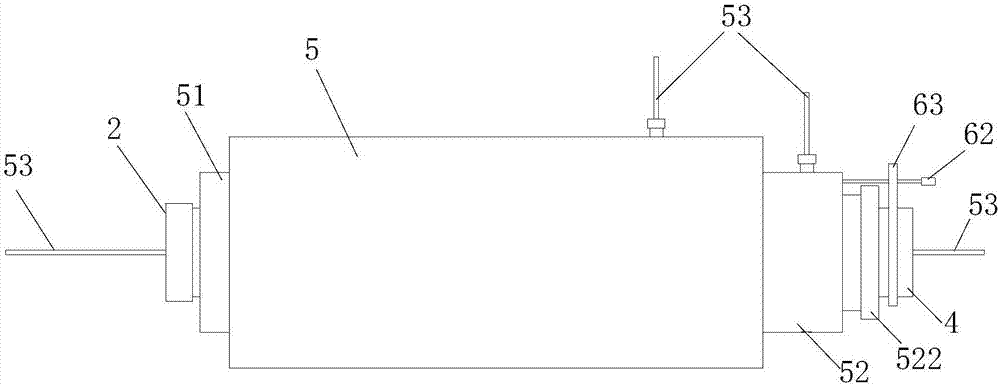

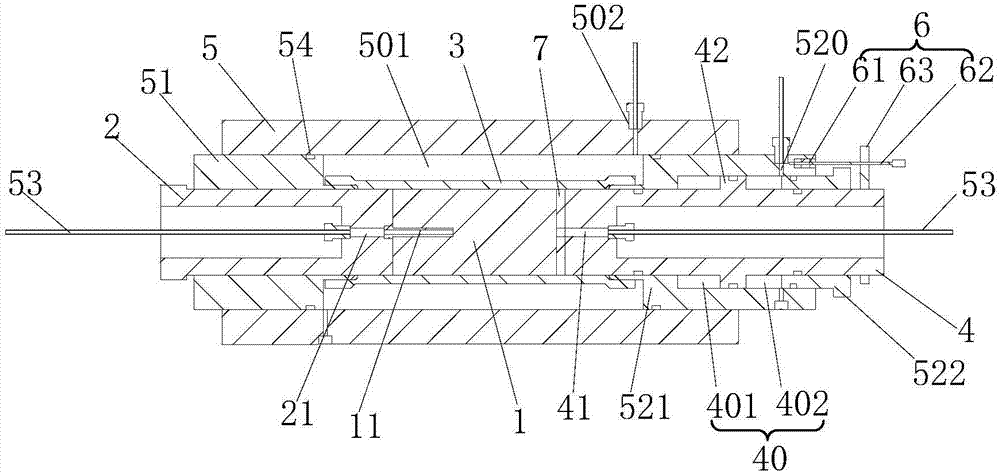

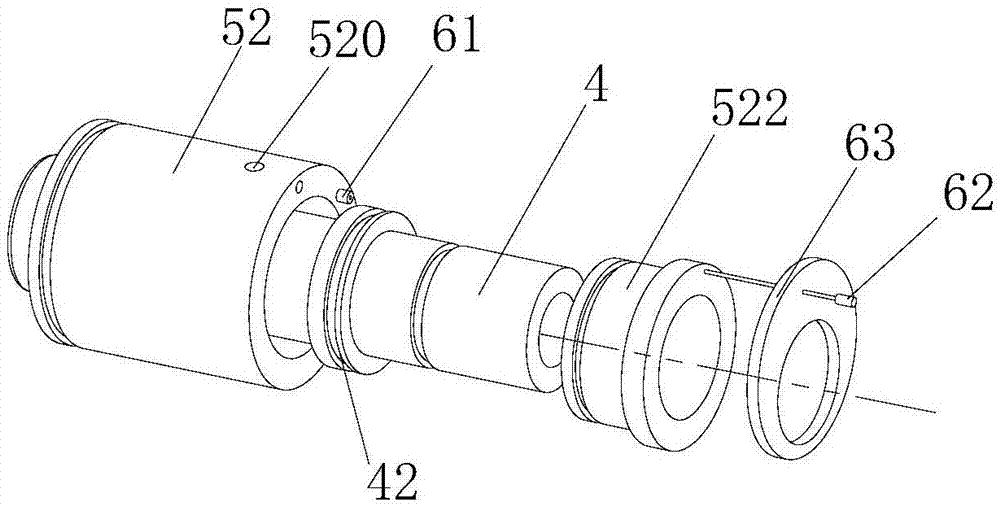

[0047]The present invention proposes a supercritical carbon dioxide rock core fracturing experimental method under pore pressure saturation. The supercritical carbon dioxide rock core fracturing experimental method has the following steps: a) processing the rock material into a test piece of a predetermined size; A groove is drilled at one end and a simulated wellbore is installed, and the outer end of the simulated wellbore is plugged into the filling channel of the left plug. After that, the test piece is placed in the sealant sleeve, and the two The end sleeve is set on the left plug and the right plug; b) The clamping sleeve is sleeved on the left plug, the sealant sleeve and the right plug, and the two ends of the sleeve are correspondingly passed through the left end sleeve and the right plug. The right end sleeve is in close contact with the left plug and the right plug, forming a ring cavity with the sealing rubber sleeve, and the right plug can move relative to the rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com