Test system for foaming times and oil surface stability of three-phase foam and test method thereof

A technology of stability testing and foaming ratio, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as single determination of foaming ratio or stability, inability to respond well to foam effects, and inability to measure foam stability. Achieve the effect of saving raw materials, simple structure and powerful function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Specific steps:

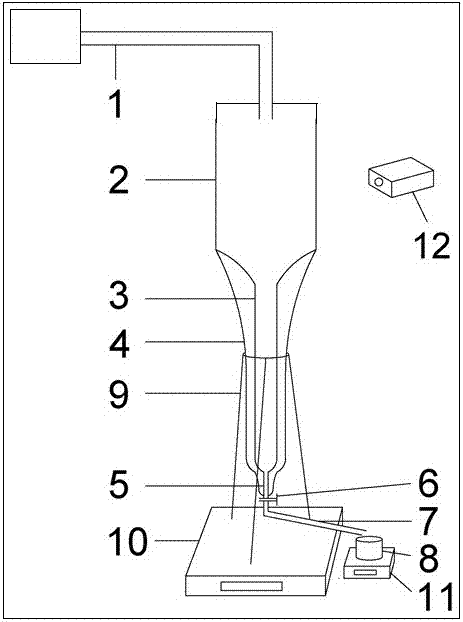

[0022] Attached figure 1 Build the three-phase foam expansion ratio and oil surface stability test system as shown, close the valve (6), pour the oil into the separatory funnel (3) to the bottomless measuring cylinder (2) and connect the separatory funnel (3) place, turn on the camera (12), electronic balance one (10), electronic balance two (11), and connect with a computer to record data. The prepared three-phase foam is added to the graduated bottomless measuring cylinder (2) through the three-phase foam delivery pipe (1). The height of foam addition is 8-10 cm. The foaming ratio is calculated by mass and volume. Whenever there is 2cm-3cm of water in the graduated dispensing pipe (5), open the control valve (6) to release the water, calculate the liquid rate according to the data recorded by the computer, and calculate the height according to the height change recorded by the camera (12) The change rate can be used to judge the foam stability, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com