Calculation method and device for metallurgical coke burning loss rate

A technology of metallurgical coke and coke, which is applied in the field of metallurgy, can solve problems such as low calculation accuracy and complex calculation and calculation of the burning loss rate of finished metallurgical coke, and achieve the effects of improving measurement accuracy, ensuring reliability, and ensuring data accuracy and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

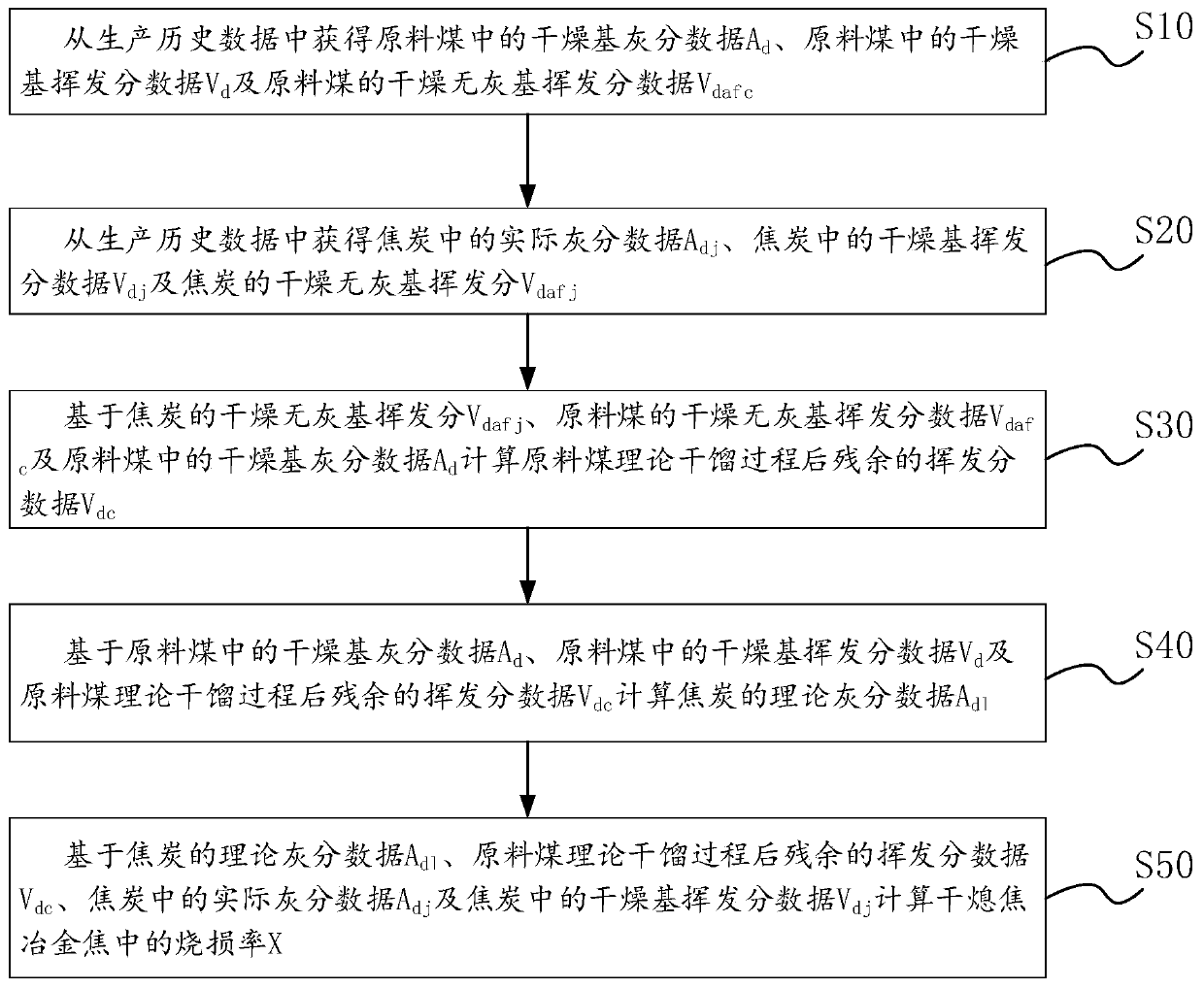

[0050] see figure 1 , the embodiment of the present invention provides a method for calculating the loss rate of metallurgical coke, which includes the following steps:

[0051] Step S10. Obtain the dry basis ash data A in the raw coal from the production history data d , Dry base volatile data V in raw coal d And raw coal dry ash-free basis volatile data V dafc .

[0052] Step S20, obtaining the actual ash data A in the coke from the production history data dj , Dry base volatile data V in coke dj and dry ash-free base volatiles of coke V dafj .

[0053] Step S30, coke-based dry ash-free volatile matter V dafj , Dry ash-free base volatile data V of raw coal dafc And the dry basis ash data in the raw coal A d Calculate the residual volatile data V after the theoretical dry distillation process of raw coal dc .

[0054] Step S40, based on the dry basis ash data A in the raw coal d , Dry base volatile data V in raw coal d and the residual volatile matter data V afte...

Embodiment 2

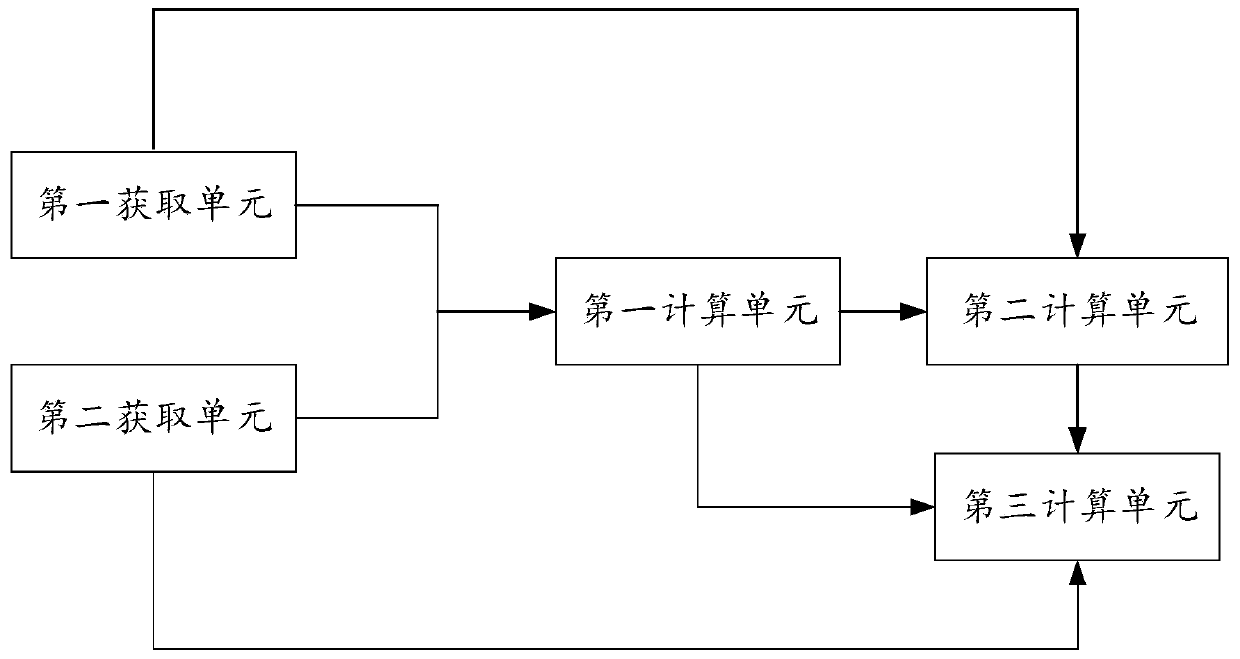

[0073] Based on the same inventive concept, see figure 2 , the present embodiment provides a metallurgical coke burning rate calculation device, including:

[0074] The first acquisition unit is used to obtain the dry basis ash data A in the raw coal from the production history data d , Dry base volatile data V in raw coal d And raw coal dry ash-free basis volatile data V dafc .

[0075] The second acquisition unit is used to obtain the actual ash data A in coke from the production history data dj , Dry base volatile data V in coke dj And coke dry ash-free basis volatile data V dafj .

[0076] First calculation unit for coke-based dry ash-free basis volatile data V dafj , Dry ash-free base volatile data V of raw coal dafc And the dry basis ash data in the raw coal A d Calculate the residual volatile data V after the theoretical dry distillation process of raw coal dc .

[0077] The second calculation unit is used for the dry base ash data A based on the raw coal d...

Embodiment 3

[0084] Based on the same inventive concept, see image 3 , the present invention also provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the following steps are implemented:

[0085] Obtain dry basis ash data in raw coal from production history data A d , Dry base volatile data V in raw coal d And raw coal dry ash-free basis volatile data V dafc .

[0086] Obtain actual ash data in coke from historical production data A dj , Dry base volatile data V in coke dj And coke dry ash-free basis volatile data V dafj .

[0087] Volatile data on coke-based dry ash-free basis V dafj , Dry ash-free base volatile data V of raw coal dafc And the dry basis ash data in the raw coal A d Calculate the residual volatile data V after the theoretical dry distillation process of raw coal dc .

[0088] Based on dry basis ash data in raw coal A d , Dry base volatile data V in raw coal d and the residual vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com