Phase loss fault tolerant control method for non-ideal sinusoidal counter electromotive force permanent magnet synchronous motor

A permanent magnet synchronous motor, back electromotive force technology, applied in the direction of motor control, torque ripple control, control system, etc., can solve the problem of non-fault phase winding current surge, motor torque ripple increase and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

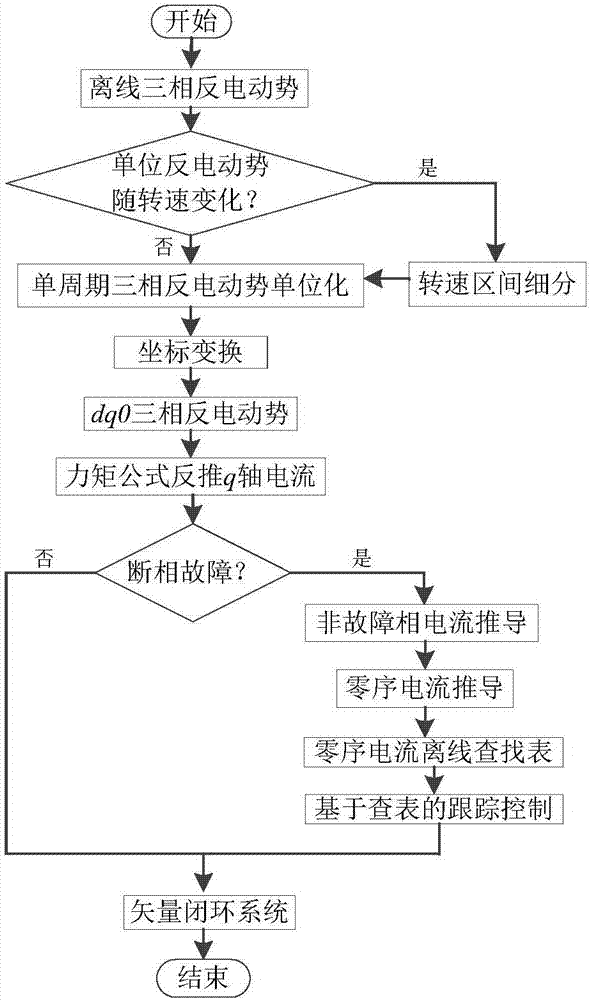

[0073] Such as figure 1 Shown, the method of the present invention realizes as follows:

[0074] The first step is to use the oscilloscope to collect the waveforms of the three-phase electromotive force of the permanent magnet synchronous motor at different speeds, and derive the discrete data of the three-phase electromotive force of the permanent magnet synchronous motor that changes with time in the oscilloscope, convert the time into a phase, and extract a Periodic three-phase opposite electromotive force.

[0075] The second step is to unitize the three-phase electromotive force of the permanent magnet synchronous motor at different speeds. When the unit back-electromotive force waveform does not change much in the full speed range of the motor, it only needs to process the three-phase electromotive force of one cycle at any speed. Get t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com