Real-time closed-loop control system for film coating and control method thereof

A closed-loop control and film thickness technology, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the deterioration of film uniformity, there is no method for accurately preparing non-uniform films, and the uniformity cannot be compensated Real-time changes and other issues to achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

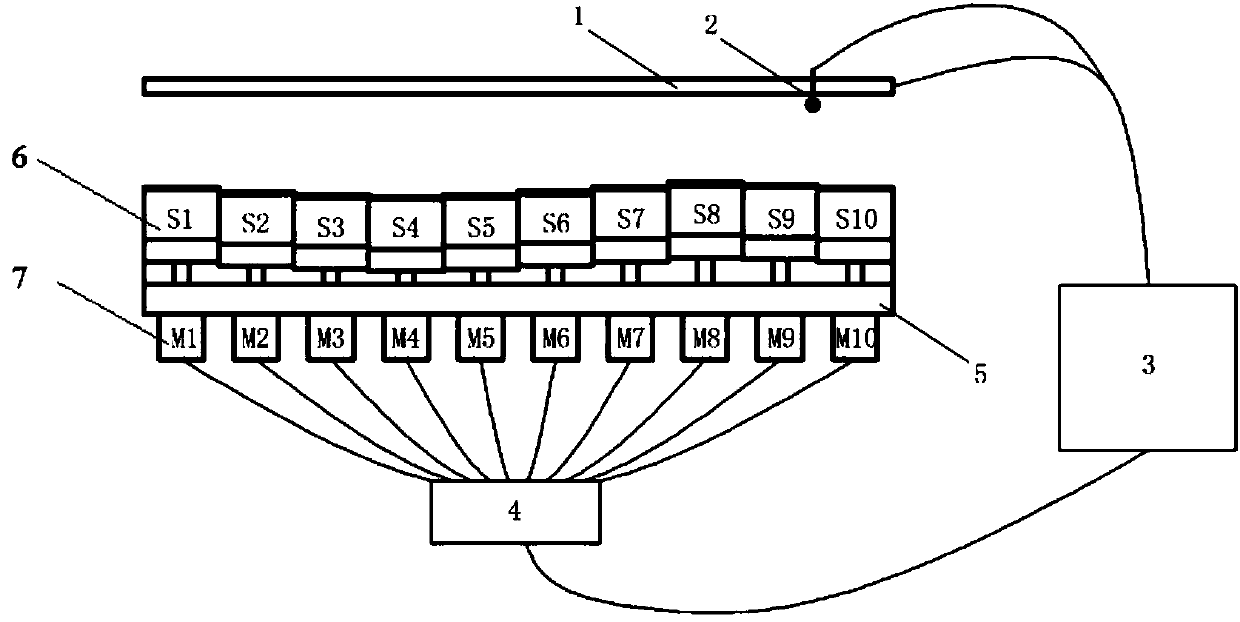

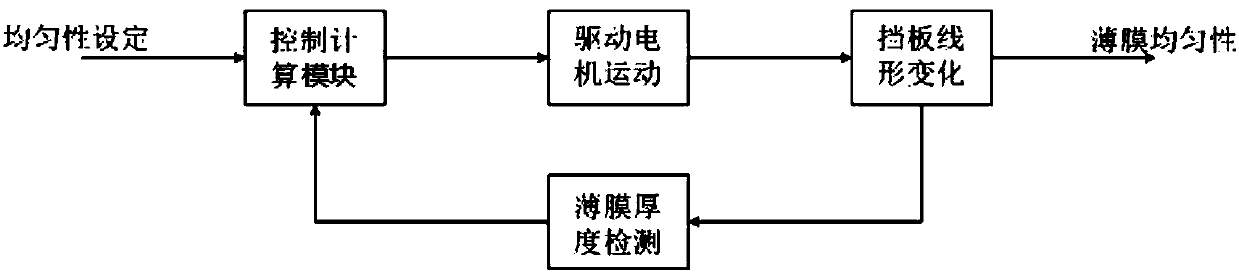

[0032] Attached below figure 1 and 2 , clearly and completely describe the technical solution of the present invention. Based on the implementation of the present invention, all other implementations obtained by persons of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

[0033] Such as figure 1 As shown, a real-time closed-loop control system for a large-diameter optical thin film of the present invention includes: a probe moving guide rail 1, a film thickness monitoring probe 2, a control calculation module 3, a motor drive module 4, a baffle support frame 5, a baffle and a drive motor7.

[0034] Among them, the probe moving guide rail 1 provides a reciprocating path for the film thickness monitoring probe 2. It has a position information feedback function and can send the position information of the film thickness monitoring probe 2 to the control calculation module 3. The track shape of the probe moving gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com