plasma nozzle

A plasma and nozzle technology, applied in the field of plasma nozzles, can solve problems such as easy oscillation and combustion instability, and achieve the effects of eliminating dissipation, simplifying structure, and enhancing swirl intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

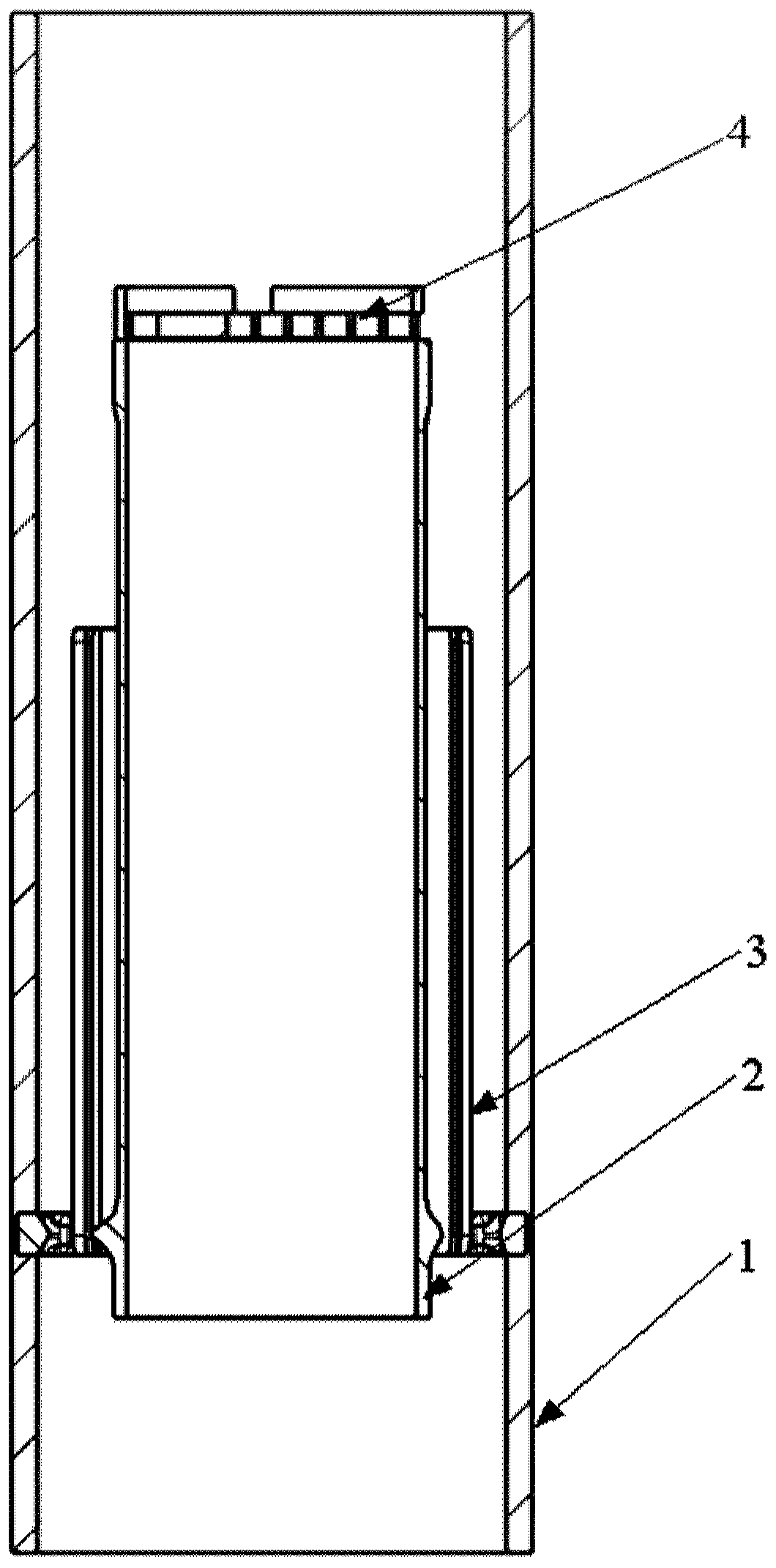

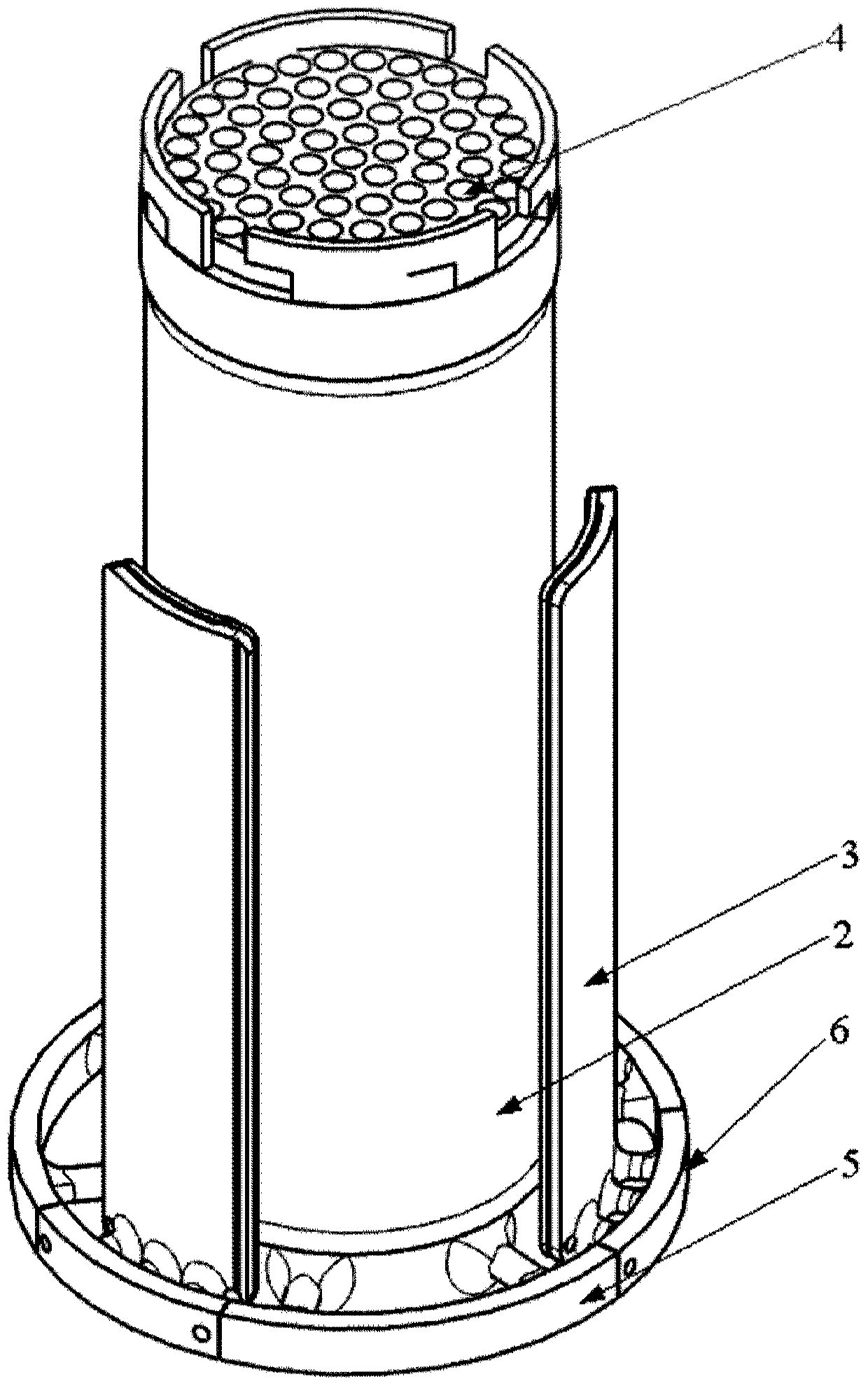

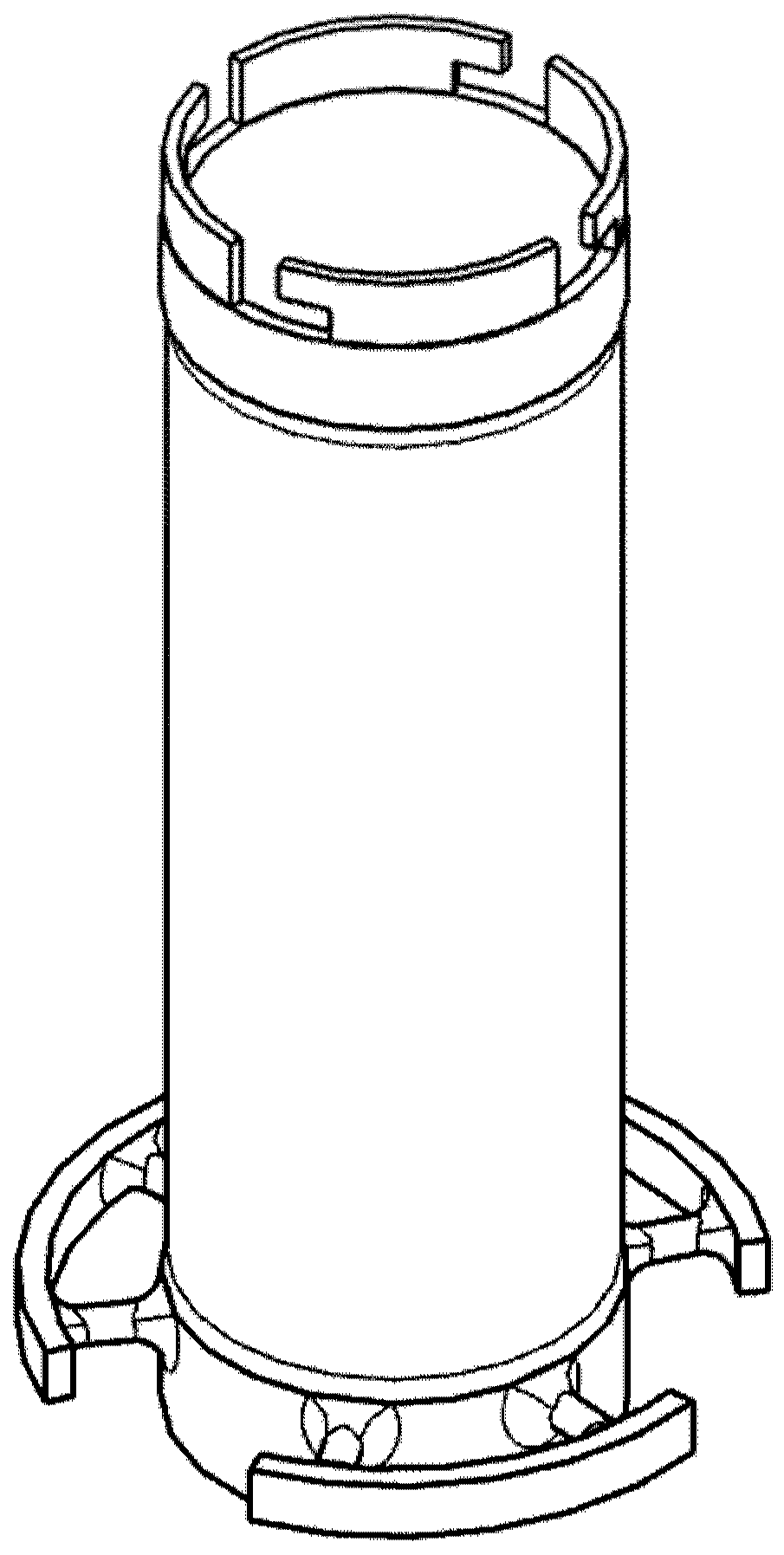

[0035] Based on various technical defects of the existing technology, in order to solve the main challenges faced by the plasma flow control technology: reduce the dissipation effect of the wall surface, enhance the control strength of the plasma flow; and improve combustion stability, reduce NO x To generate, reduce flow loss, and prevent flashback, the present invention provides a plasma nozzle, which includes: an axial suspension plate, at least one power supply, and at least one plasma exciter. The axial suspension plate is provided with at least one plasma exciter, under the action of the excitation voltage provided by the power supply, the plasma-induced flow can form a free jet at the edge of the axial suspension plate, thus eliminating the The dissipation of plasma-induced flow momentum by the wall boundary layer can effectively enhance the swirl intensity and stabilize combustion.

[0036] In order to make the object, technical solution and advantages of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com