A spray dust remover

A dust collector and machine body technology, applied in the separation method, the use of liquid separation agent, the separation of dispersed particles, etc., can solve the problems of low visibility at the job site, affect the health of the workers, and affect the safety of the job, so as to ensure the health and safety of the job Safety, ensuring work efficiency, and ensuring the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

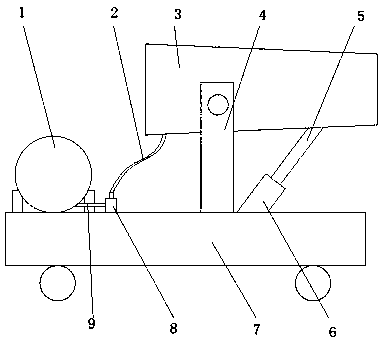

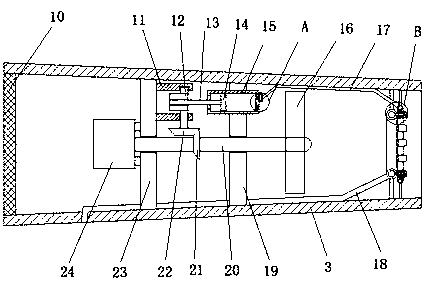

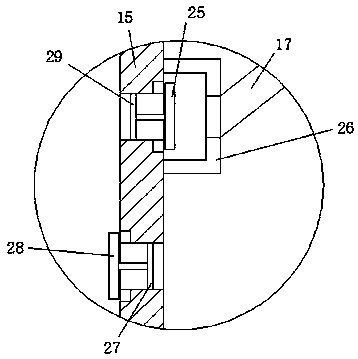

[0029] see Figure 1-4 , a spray dedusting machine, comprising a body 7, a vertical plate 4 is fixedly connected to the body 7, and an end of the vertical plate 4 away from the body 7 is rotatably connected with a blower 3, and the body 7 is connected with a water storage tank 1 and a water pump 8, and the water pump 8. The water inlet end is connected to the water storage tank 1 through the connecting pipe 9. The air outlet end of the air cylinder 3 is firmly connected with an annular water pipe 36 through a stabilizing rod. The annular water pipe 36 is connected with a water inlet pipe 18. One end of the hose 2 passes through the blower tube 3 and is connected with the hose 2. The end of the hose 2 away from the water inlet pipe 18 is connected with the water outlet of the water pump 8. The annular water pipe 36 is connected with a plurality of outlet pipes 34, and the outlet pipe 34 is far away from the ring water pipe 36. One end is connected with a spray head 33, the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com