Stirring device with convenient-to replace stirring shaft

A technology for convenient replacement and stirring devices, applied in the direction of mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of difficulty in meeting various use needs, single structure, and many processes, and achieve suitable promotion and use , Guaranteed operation effect, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

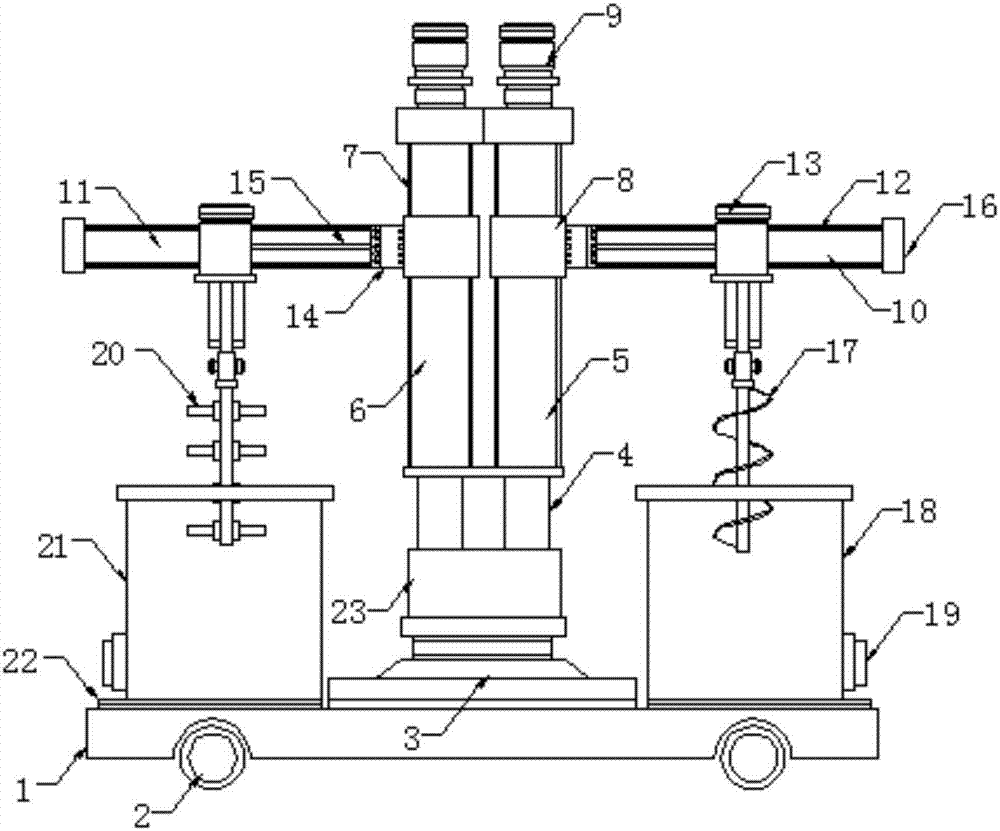

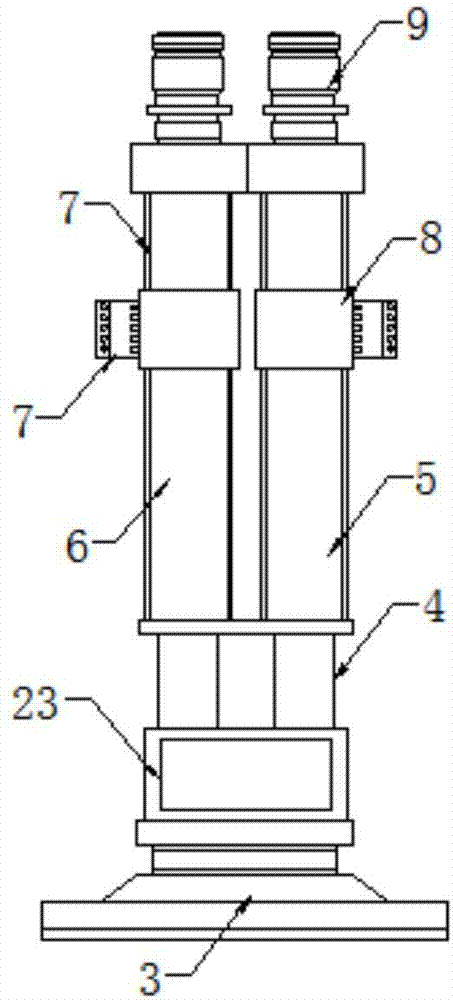

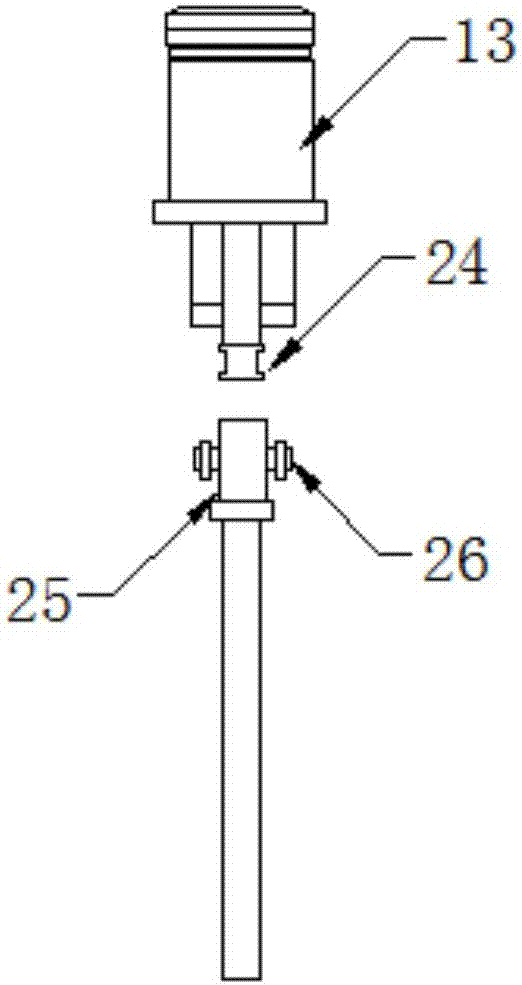

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: including support base plate 1, roller 2, rotating base 3, jacking rod 4, first bracket 5, second bracket 6, longitudinal slide rail 7, lifting slide seat 8, lifting Motor 9, first beam 10, second beam 11, transverse slide rail 12, stirring motor 13, transverse cylinder 14, telescopic rod 15, limit end cap 16, first stirring shaft 17, first stirring drum 18, discharge port 19, the second stirring shaft 20, the second mixing drum 21, the chute 22, the hydraulic cylinder 23, the positioning joint 24, the limit interface 25 and the limit pin 26, the support base 1 is fixedly installed with a rotating base 3, and the rotating base 3 is fixedly installed with a hydraulic cylinder 23, and the output end of the hydraulic cylinder 23 is movably connected with the first support 5 and the second support 6 through the jacking rod 4, and the first support 5 and the second support 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com