Gypsum board preparation system with elastic port discharge device

An elastic and scraper technology, which is applied in the direction of unloading device, sales raw material supply device, liquid ingredient supply device, etc., can solve the problems of material leakage at the connection, loose screws, shortening the service life of the feeding device, etc., to extend the service life , Unloading smoothly, solving the effect of unstable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

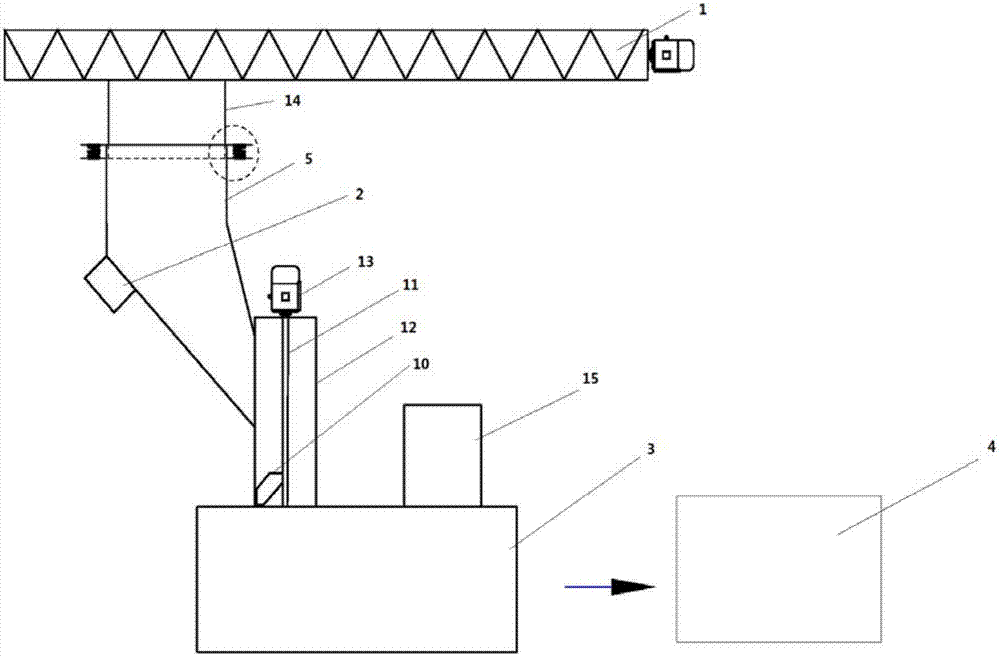

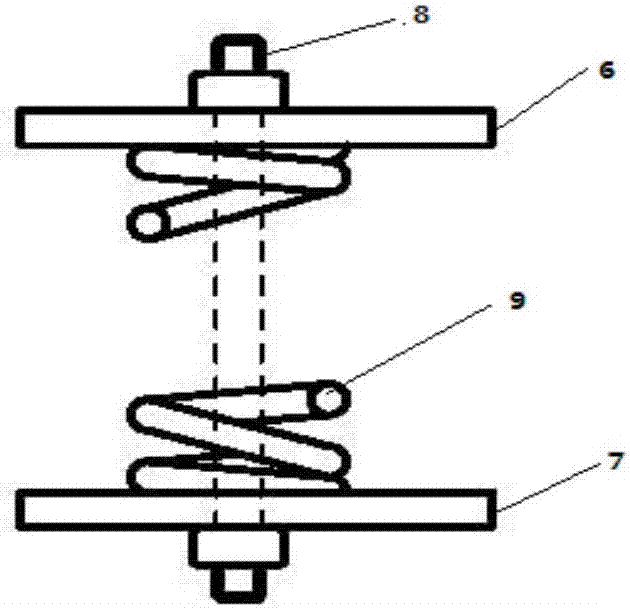

[0030] Such as figure 1 As shown, a system for preparing gypsum board with an elastic mouth feeding device includes a feeding reamer 1, a vibrating motor 2, a mixer 3 and a board making line 4, and also includes a feeding device and a scraping device. The blanking device includes an inclined slide 5 , an upper flange 6 , a lower flange 7 and a screw 8 . The scraping device includes a scraper box 12 and a scraper motor 13, the scraper box 12 is provided with a scraper bar 11 and a scraper plate 10, the scraper motor 13 is arranged above the scraper box 12, and is passed through the scraper bar 11 drives the scraper 10 to scrape. The left end of feeding reamer 1 is provided with feeding opening 14, and this feeding opening 14 embeds in the 10cm place of inclined slide 5, and the outer wall of feeding opening 14 is close to the inwall of inclined slide 5; The upper flange 6 is welded around the feeding port 14, and the lower flange 7 is welded around the inclined slide 5 that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com