Differential planetary reduction gear for bridge crane

A bridge crane, planetary reduction technology, applied in the direction of transmission, transmission parts, gear transmission, etc., to achieve the effect of reducing accidental losses, reducing the trouble of drive control and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

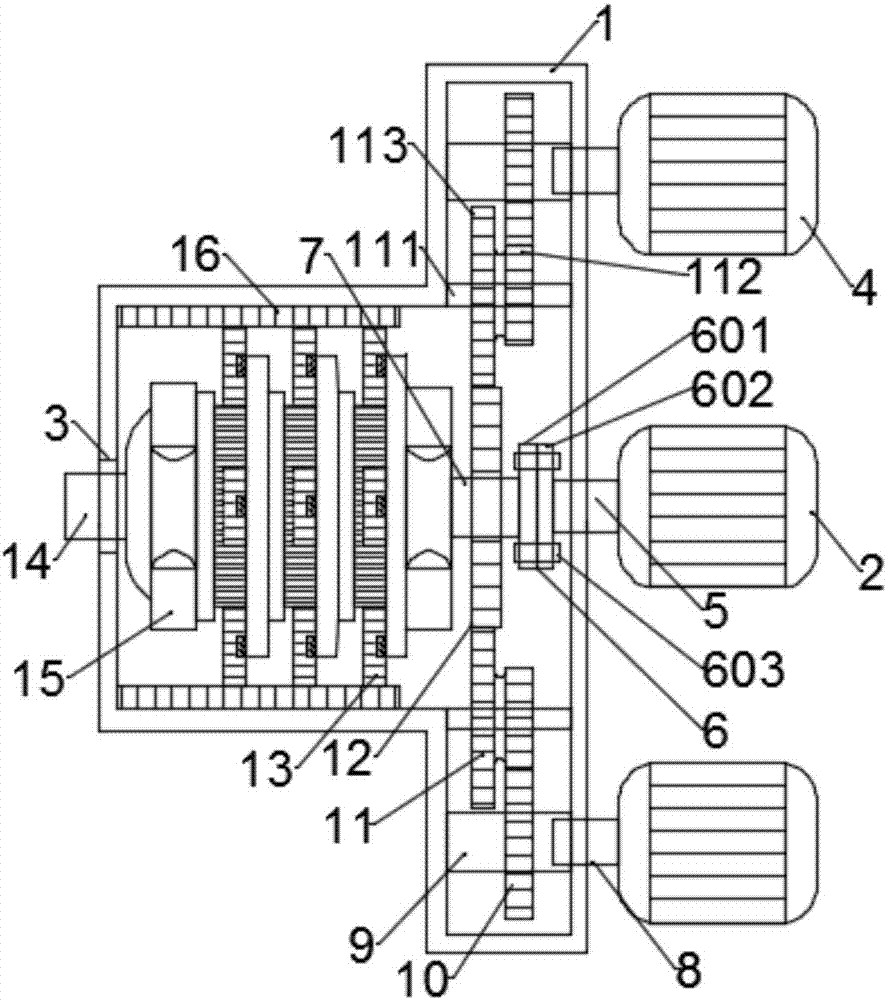

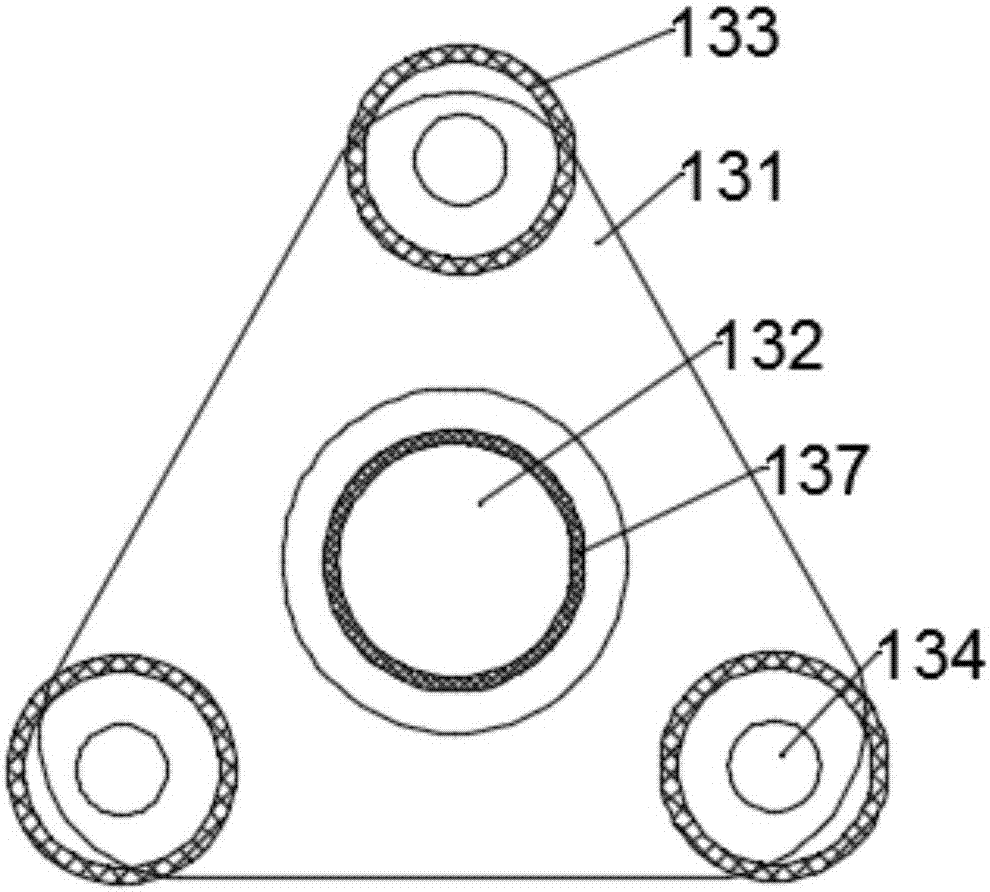

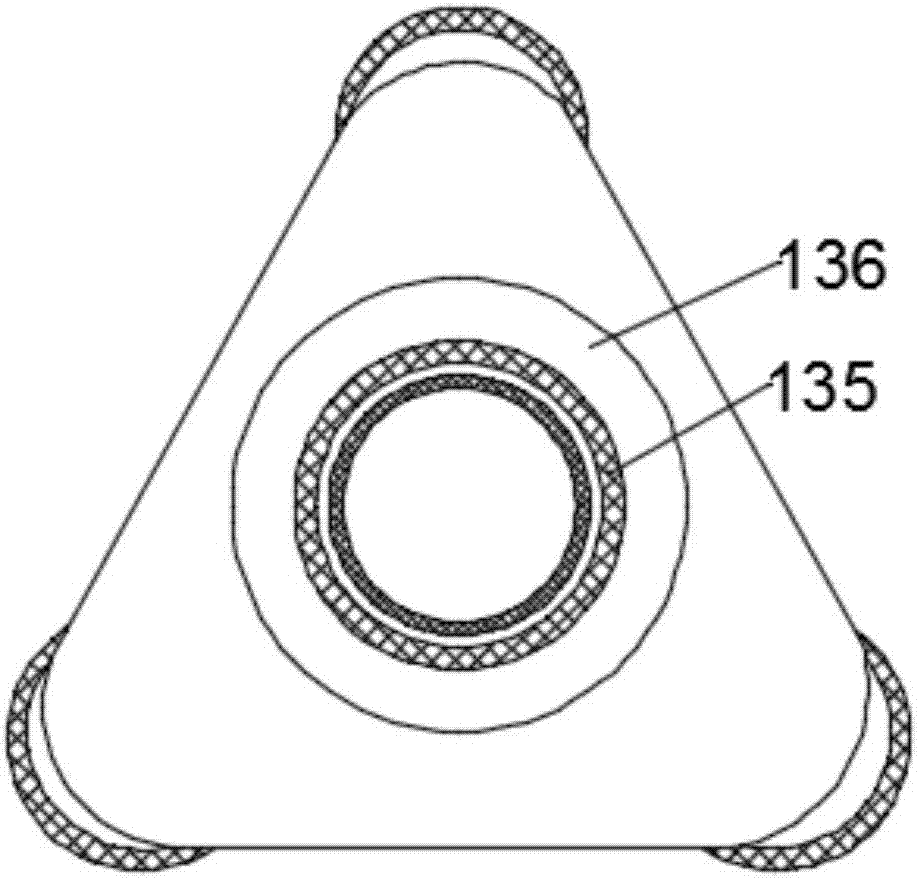

[0026] Such as figure 1 and Figure 4 As shown, the present invention provides a differential planetary reduction gear for bridge cranes, including a reduction gear frame 1, a main motor 2 is arranged outside one end of the reduction gear frame 1, and the other end of the reduction gear frame 1 An output shaft hole frame 3 is installed, and the radius of the output shaft hole frame 3 is 5mm larger than that of the output shaft 14, and the output shaft 14, the power shaft 5 and the backup power shaft 8 are all made of hard alloy, so The two sides of the main motor 2 are symmetrically installed with a spare motor 4, and the power shaft 5 of the main motor 2 is connected with a transmission shaft 7 through a flange 6, wherein the flange 6 includes an upper flange 601 and a lower flange 601. Flange 602, the upper flange 601 is connected to the transmission shaft 7, and the lower flange 602 is connected to the power shaft 5, and the upper flange 601 and the lower flange 602 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com