Manufacturing technology of backlight lamp control assembly of automotive instrument panel

A technology for automotive instrument panels and control components, which is applied to instrument panel lighting equipment, components of lighting devices, electric light sources, etc. The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

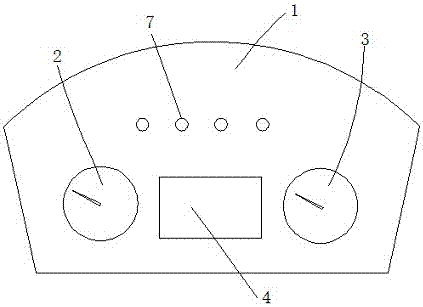

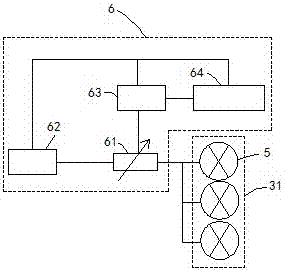

[0028] see Figure 1 to Figure 2 , the present invention provides an automobile instrument panel, comprising: a casing 1, a tachometer 2 and a speedometer 3 arranged in sequence on the casing 1, and a display screen between the tachometer 2 and the speedometer 3 4. Three backlights 5 respectively corresponding to the tachometer 2, the speedometer 3, and the display screen 4, and a backlight control assembly 6 electrically connected to the three backlights 5;

[0029] The backlight control assembly 6 includes: a digital adjustable resistor 61, a power supply 62, a processor 63, and a light sensor 64;

[0030] The three backlights 5 are connected in parallel to form a backlight module 31, the digital adjustable resistor 61, the power supply 62, and the backlight module 31 are connected in series in sequence, and the control terminal of the digital adjustable resistor 61 is connected to the processor 63 , the processor 63 is electrically connected to the light sensor 64 , and bo...

Embodiment 2

[0035] A manufacturing process of a backlight control assembly of an automobile instrument panel, the steps are as follows:

[0036] ①, structure and molding

[0037] The backlight control component is used to control the backlight in the instrument panel, including a digital adjustable resistor, a power supply, a processor, and a light sensor; three backlights are connected in parallel to form a backlight module, and the digital adjustable resistor, power supply , and the backlight module are connected in series in sequence, the control terminal of the digital adjustable resistor is electrically connected to the processor, the processor is electrically connected to the light sensor, and both the processor and the light sensor are electrically connected to the power supply; digitally adjustable Resistors, power supplies, processors, and light sensors are in one package;

[0038] The digital adjustable resistor, power supply, processor, and light sensor are all prepared accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com