Periodic-pulse thermal-imagery detection method for leaded steel material debonding defect

A multi-layer material and periodic pulse technology, which is applied in the direction of material defect testing, etc., can solve the problems of long detection time, complex phase-locked modulation system, high hardware cost, etc., and achieve the effect of low hardware cost, improved signal resolution, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

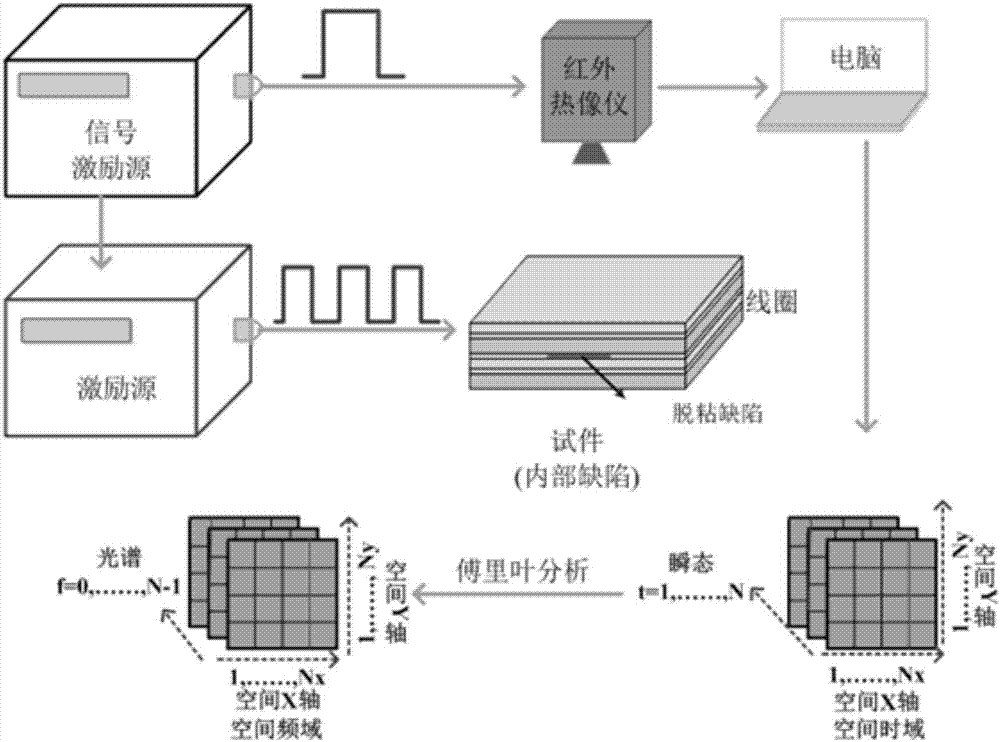

[0048] figure 1 Is the block diagram of the periodic pulse thermal imaging system.

[0049] In this example, if figure 1 As shown, the specimen is excited by periodic pulses, and according to the principle of thermal wave conduction, the surface will produce a temperature sequence of periodic changes. The change of surface temperature with time can be expressed as a superposition of two parts: a steady state part and a transient part. Solve the transient distribution of surface temperature T(0,t) according to the principle of thermal wave conduction T and the steady-state distribution T(0,t) S ,as follows:

[0050] T(0,t) T =T am +ΔT(1-e -t / τ )

[0051]

[0052] Since the principle of linear superposition is satisfied, the surface temperature change curve with time is as follows:

[0053] T(0,t)=T(0,t) T +T(0,t) S (5)

[0054] Among them, T(0,t) is the change of surface temperature with time. A is the magnitude of the transient component, q 0 is the total ene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com