Copying pulverizer for maize straws returning to field

A corn stalk and pulverizer technology, which is applied to agricultural machinery and implements, agriculture, cutting equipment and other directions, can solve the problem that corn stalk cannot meet the agronomic requirements of straw returning to the field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

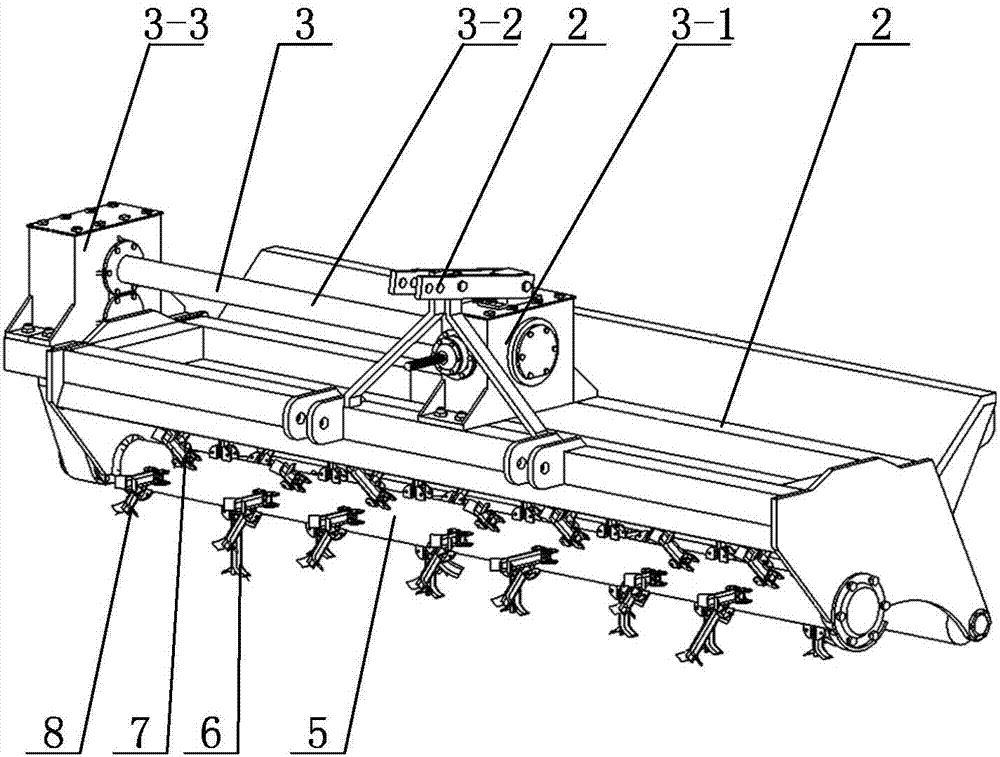

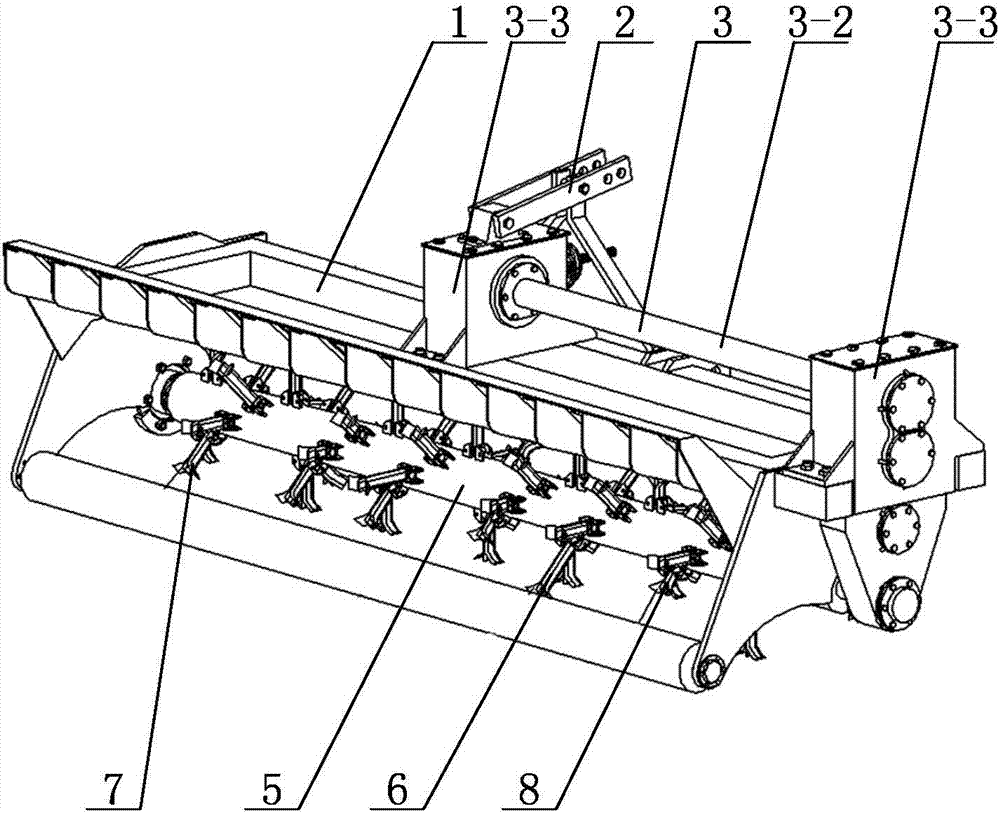

[0013] Specific implementation mode 1: Combination Figure 1 to Figure 5 To explain this embodiment, the corn stalk profiling crusher described in this embodiment includes a frame 1, a transmission mechanism 3, and a pulverizing component. The transmission mechanism 3 and the pulverizing component are installed on the frame 1, and the transmission mechanism 3 Connected with the crushing assembly.

[0014] The output shaft of the tractor drives the crushing assembly through the transmission mechanism 3.

specific Embodiment approach 2

[0015] Specific implementation manner two: combination Figure 1 to Figure 5 To explain this embodiment, the transmission mechanism 3 of the corn stalk profiling grinder described in this embodiment includes a gearbox 3-1, a transmission shaft 3-2 and a pulley assembly 3-3, and the input of the gearbox 3-1 The shaft is connected with the output shaft of the tractor, the output shaft of the gearbox 3-1 is connected with one end of the transmission shaft 3-2, and the other end of the transmission shaft 3-2 is connected with the crushing assembly through the pulley assembly 3-3.

[0016] The pulley assembly 3-3 is composed of a driving pulley, a belt and a driven pulley. The driving pulley is sleeved on the transmission shaft 3-2, the driven pulley is sleeved on the main shaft 4, and the driving pulley is connected to the driven pulley through a belt. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

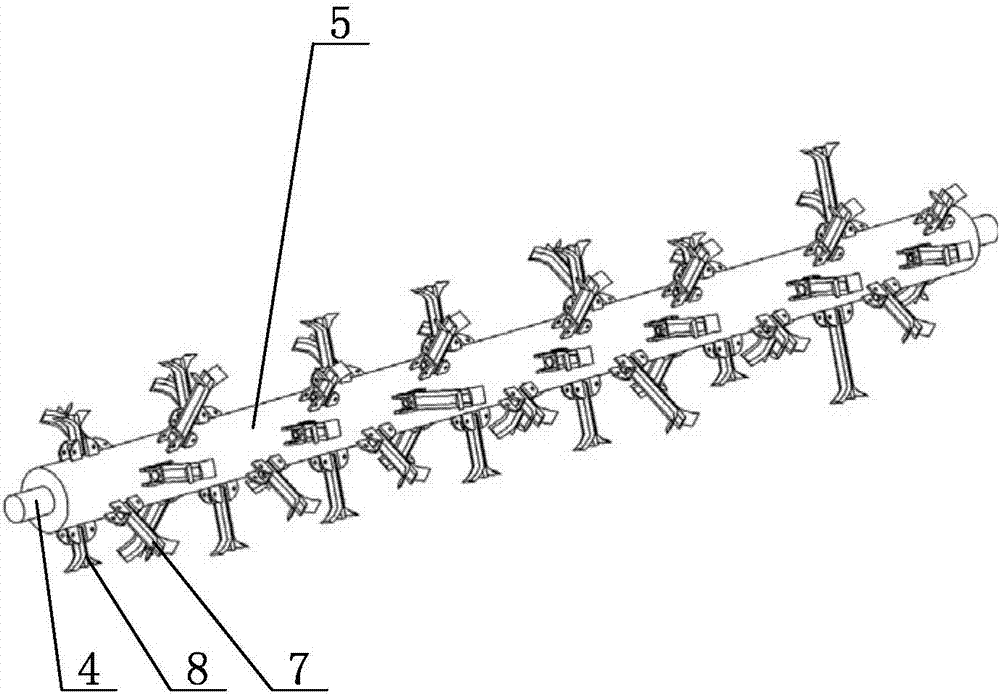

[0017] Specific implementation mode three: combination Figure 1 to Figure 5 To explain this embodiment, the corn stalk profiling crusher described in this embodiment is characterized in that the crushing assembly includes a main shaft 4, a roller 5, a plurality of long cutters 6, and a plurality of middle cutters 7. And a plurality of short cutting knives 8, the roller 5 is sleeved on the main shaft 4, and a plurality of long cutting knives 6, a plurality of middle cutting knives 7 and a plurality of short cutting knives 8 are installed on the roller 5. The other components and connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com