Header of corn cutter for harvesting stem and ear of with self-adaption row spacing

A self-adaptive, harvester technology, applied in harvesters, applications, cutters, etc., can solve the problems of waste of resources, inability to harvest, and difficulty in mechanical harvesting of corn, and achieve convenient installation and matching, improved operation efficiency, and good return to the field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

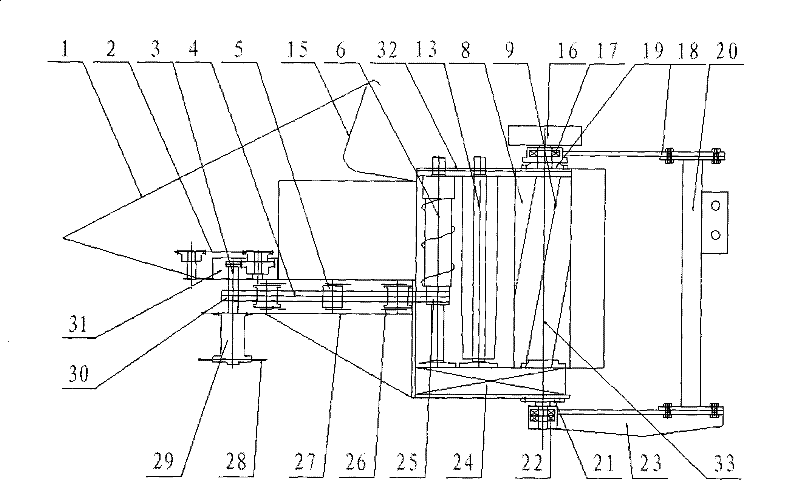

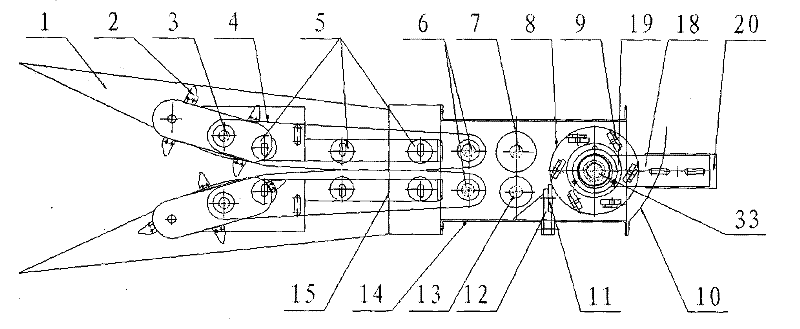

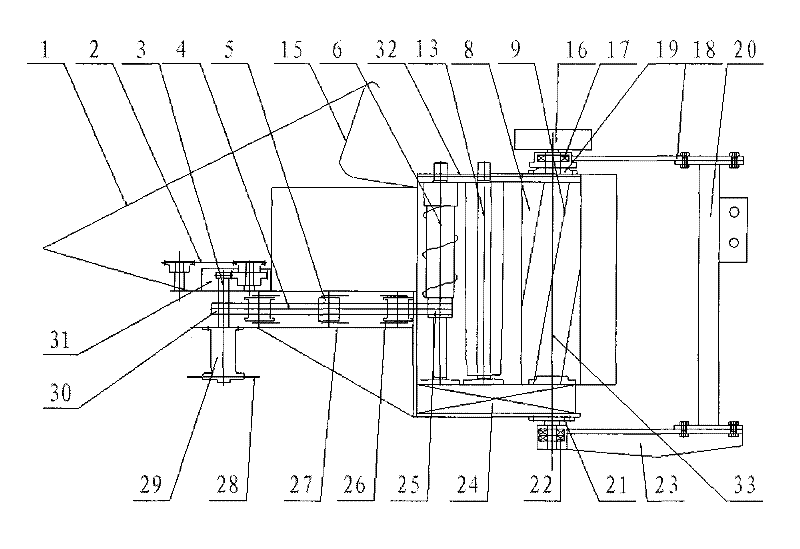

[0024] Example 1 as figure 1 , figure 2 As shown, it is a schematic diagram of the structure of the single harvesting unit. The harvesting unit of the self-adaptive line spacing stem ear harvester header is connected with one end of the upper shaft support frame 18 through the upper bearing 17 respectively, and the lower bearing 22 is respectively connected with the harvesting unit below. One end of the following rotating shaft support frame 23 is rotatably connected, and the other end of the upper rotating shaft support frame 18 and the following rotating shaft support frame 23 is fixed on the harvester frame 20 respectively. Harvesting unit is fixedly connected and constituted by header frame mechanism 27 and main frame mechanism, and header frame mechanism 27 is connected on the front part of main frame mechanism, and rotating shaft hollow seat 19 and lower rotating shaft seat 21 on the main frame mechanism respectively pass upper bearing 17 and lower The bearing 22 is ro...

Embodiment 2

[0028] Embodiment 2 is that the harvesting unit is the corn harvester header device of the stem and ear combined harvesting type of two unit body structures, and it is that the harvesting unit of 2 unit body structures is connected in parallel on the harvester frame 20 on the same plane, Increase the corresponding tractor horsepower, and each harvesting unit is rotatably connected with the upper rotating shaft support frame 18 and the lower rotating shaft support frame 23 and the rotating shaft of a corresponding set. The two harvesting units can rotate left and right around the roller cutter shaft 33, and automatically adjust according to the change of the corn row spacing, so that the distance between the center points of the stalk feeding entrances of two adjacent harvesting units is automatically consistent with the corn row spacing.

[0029] In the present embodiment, the blower recovery device is adopted to replace the broken stalk guide plate 10, and the silage fodder ca...

Embodiment 3

[0030] Embodiment 3 is that the harvesting unit is the corn harvester header device of the stem and ear combined harvesting type corn harvester of four unit body structures, and it is that the harvesting units of 4 unit structures are connected in parallel on the harvester frame 20 on the same plane, Increase the corresponding tractor horsepower, and each harvesting unit is rotatably connected with the upper rotating shaft support frame 18 and the lower rotating shaft support frame 23 and the rotating shaft of a corresponding set. The four harvesting units can freely rotate left and right around their respective roller cutter shafts 33, and automatically adjust according to the change of the corn row spacing, so that the distance between the center points of the stalk feeding entrances of two adjacent harvesting units is automatically consistent with the corn row spacing . Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com