Automatic egg collection device

An egg-collecting and automatic technology, applied in poultry industry, applications, poultry cages or houses, etc., can solve problems such as affecting the health of workers, high cost of human resources, and impact on poultry growth, so as to ensure physical health and reduce manpower. Resource cost, good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

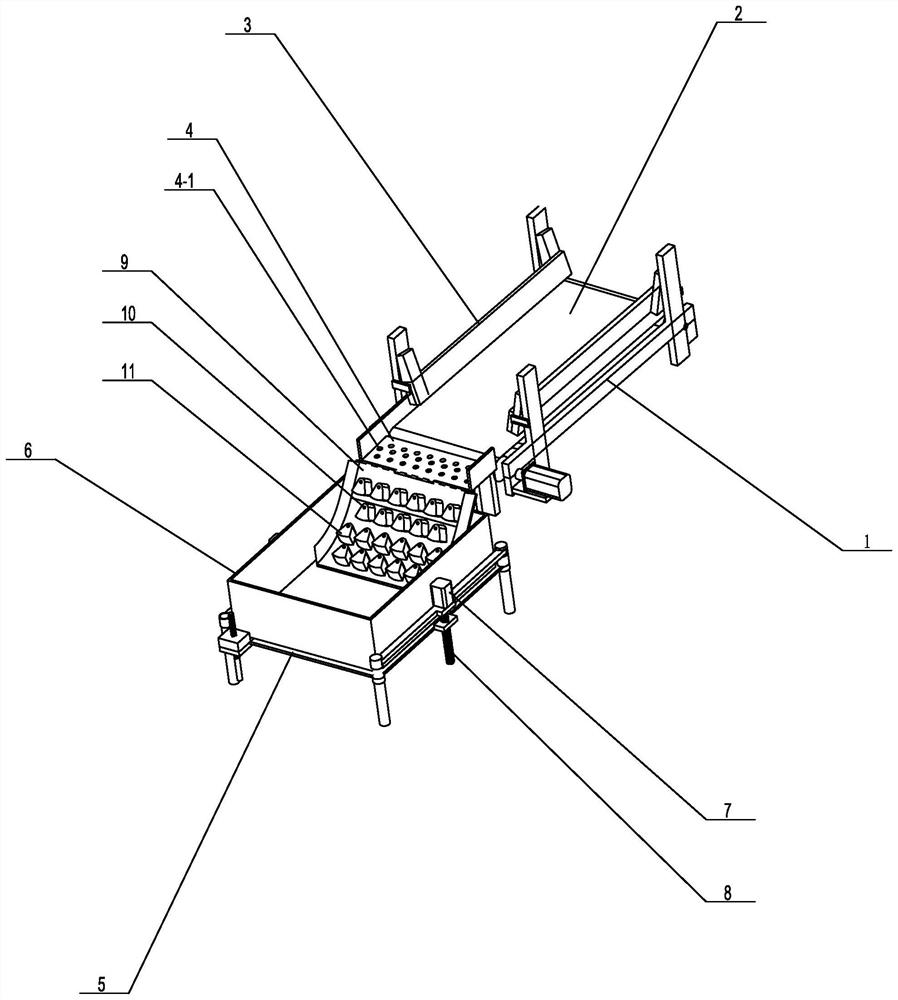

[0018] Such as figure 1 As shown, a specific embodiment of the present invention is proposed. The automatic egg collection device includes a delivery bed and a collection mechanism located at the end of the delivery bed. The conveyor belt delivery bed 2 on the bed frame 1, the end of the conveyor belt delivery bed 2 is provided with a roller, and the roller is rotated by a motor, and then the conveyor belt delivery bed 2 is conveyed, and the transmission belt delivery bed Both sides of 2 are provided with retaining panels 3, and the end is provided with an inclined transmission plate 4 connected with it. It is best not to set the inclined transmission plate 4 too inclined, so as to avoid the poultry eggs falling too fast due to gravity and cause too much momentum. Further crushing, in this embodiment, the inclination angle of the inclined transmission plate 4 is set to be less than or equal to 10°. In order to increase the load-bearing strength of the delivery bed 2 with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com