Hot pot table capable of reducing oil fume

A hot pot table and oil fume technology, which is applied in the field of tables, can solve the problems of occupying upper space, pot cover space, polluting air, etc., and achieves the effects of saving energy consumption, simple installation and maintenance, and reducing diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

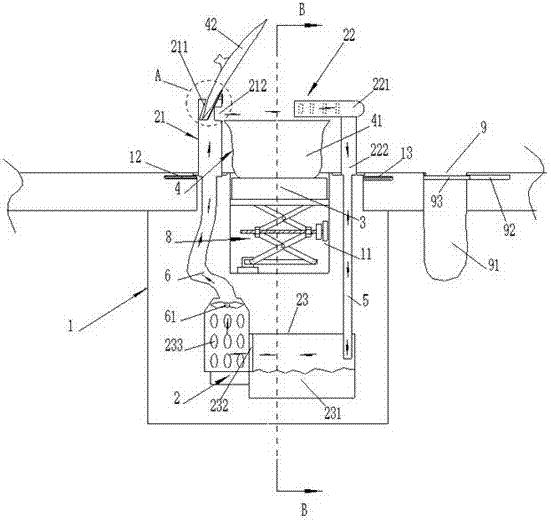

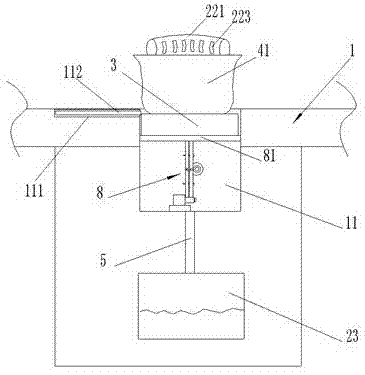

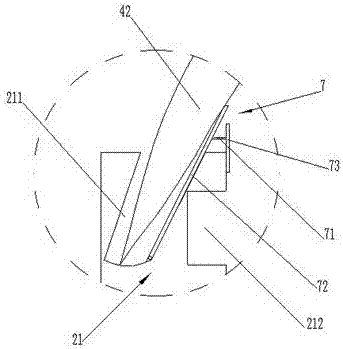

[0034] see Figure 1-5 , a hot pot table for reducing cooking fumes, comprising a table body 1, a cooking fume removal device 2, an electromagnetic board 3 arranged on the upper end of the table body 1, and a hot pot 4 placed on the electromagnetic board 3; the hot pot 4 includes a pot body 41 and a cover on the pot The pot cover 42 on the body 41; the oil fume removal device 2 includes a blowing pipe 21 vertically arranged on one side of the pot body 41, a suction cover 22 arranged on the other side of the pot body and a processing box 23 arranged inside the table body 1 The upper end of the air blowing pipe 21 has a pot lid placement groove 211, and the pot lid placement groove 211 is inclined toward the side of the pot body 41 from bottom to top; Air outlet through hole 212, outlet air through hole 212 is positioned at pot body 41 tops; P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com