A mechanical energy absorbing metamaterial based on a buckle structure and its manufacturing method

A buckle structure and metamaterial technology, applied in chemical instruments and methods, other household appliances, protective clothing, etc., can solve problems such as waste, lack of adjustability, and high cost of engineering use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

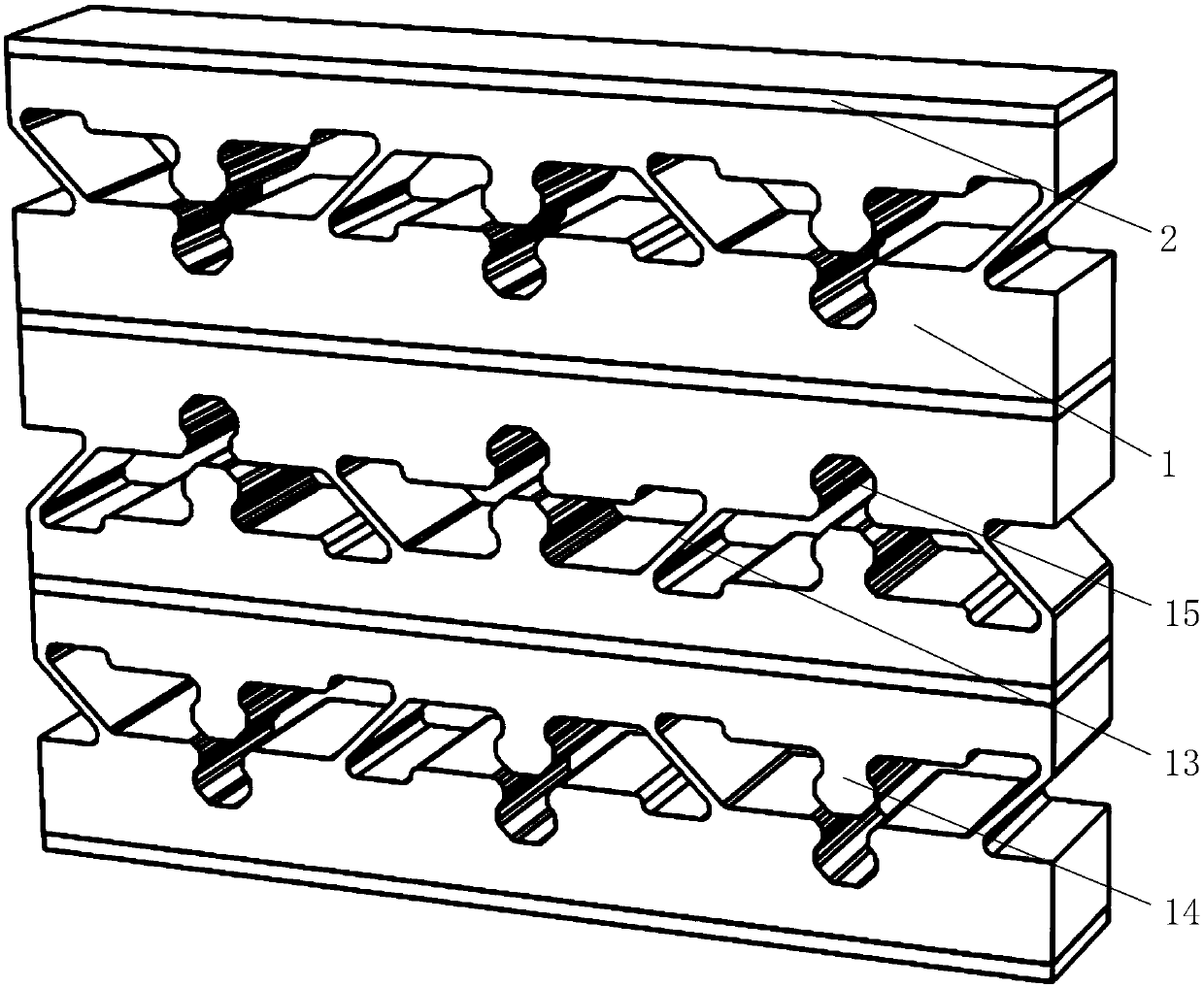

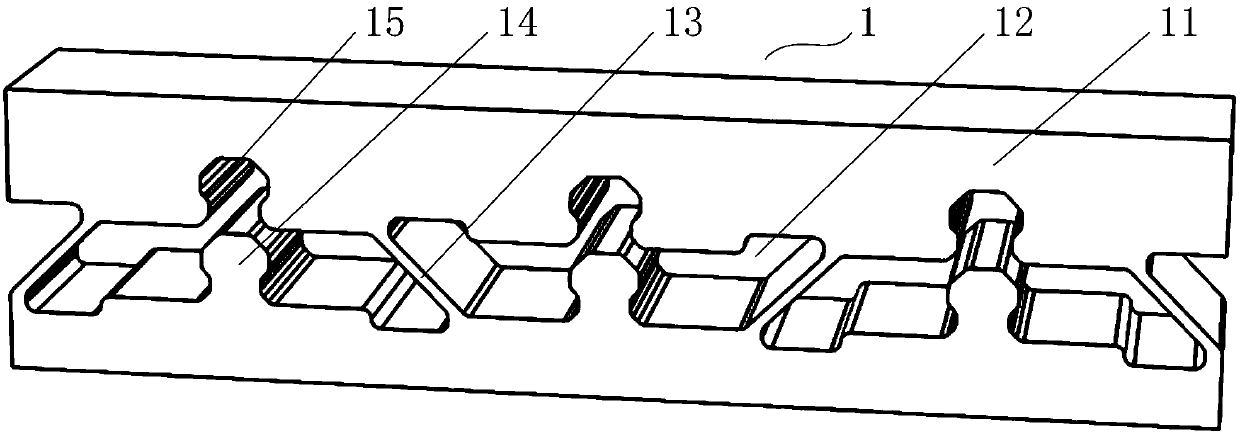

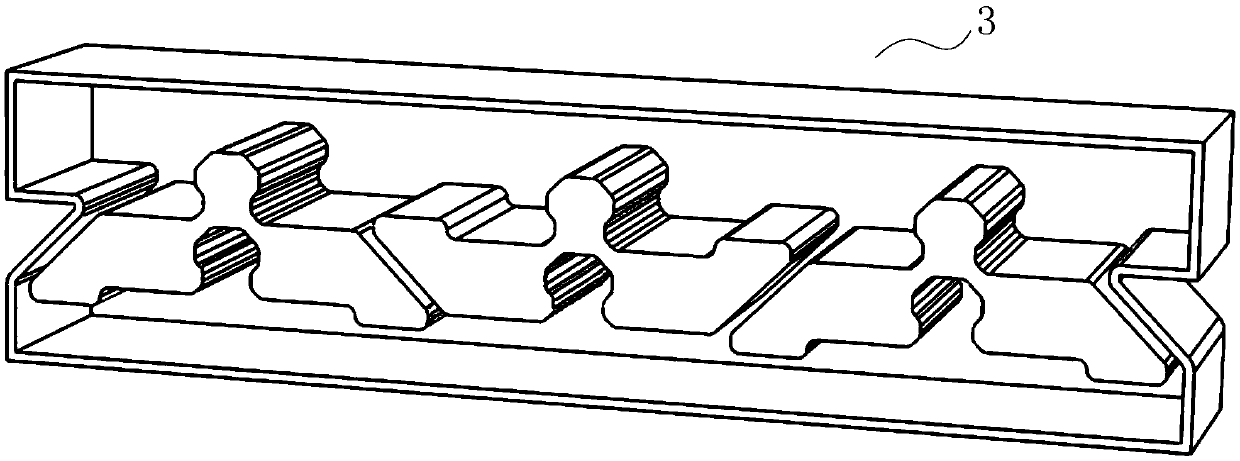

[0038] 1) Use Solidworks 3D modeling software to design the mold for the designed structure, and design a mechanical energy absorbing metamaterial with a three-layer array. The buckle structure has an in-out angle of 45°, a slant arm width of 1.5mm, a buckle opening width ratio of 0.8, and a metamaterial thickness of 20mm. The structure of its single-layer mechanical metamaterial 1 is as follows figure 2 As shown, the single-layer mechanical metamaterial mold 3 deduced according to the structure of the single-layer mechanical metamaterial 1 is as follows image 3 shown.

[0039] 2) Import the model file of the single-layer mechanical metamaterial mold 3 into the 3D printing device, and the printing material used is photosensitive resin to produce the resin frame of the single-layer mechanical metamaterial mold 3 .

[0040] 3) Mix the Sylgard-184PDMS body and the cross-linking agent at a ratio of 7:1, stir and mix them thoroughly, let stand for 24 hours, and discharge the ai...

Embodiment 2

[0045] Other steps of the present embodiment are exactly the same as those in Embodiment 1, and the difference is only in step 6): adopting the Mobil-15W-30 type lubricating oil produced by Exxon Mobil Corporation to lubricate the buckle 14 and the surface of the draw groove 15, Obtain a mechanical energy absorbing metamaterial with a coefficient of friction of 0.1; test its force-displacement curve, the results are as follows Figure 4 shown by the dotted line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com