Biodegradable staple and its production process

A staple and biological technology, which is applied in the field of biodegradable staples and their production processes, can solve the problem that staple materials cannot take into account the plastic deformation ability and corrosion resistance, avoid economic and physical burdens, and ensure biological Safety and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will now be described in further detail.

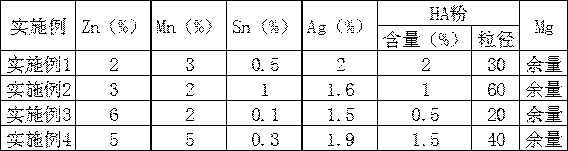

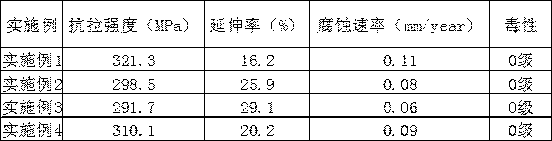

[0043] A biodegradable staple, the composition of its components by mass percentage is shown in the following table:

[0044]

[0045] A production process of biodegradable staples, comprising the following steps:

[0046] 1) Weigh each component in proportion;

[0047] 2) Dry the components weighed above in an oven at 100°C for 1-2 hours;

[0048] 3) Add the weighed Zn, Mn, Sn, Ag and Mg into the graphite crucible, after vacuuming, pass it into the BF 3 and CO 2 The mixed gas is used as a protective gas, and after the components are completely dissolved at 700-800 ° C, keep it for 10-20 minutes;

[0049] 4) Add HA powder into a graphite crucible containing Zn, Mn, Sn, Ag and Mg for melting, and stir evenly to obtain a melting solution;

[0050] 5) Pour the smelting solution into a pre-dried graphite mold to obtain a magnesium alloy ingot;

[0051] 2. Heat treatment process of magnesium alloy:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com