Concrete block forming wet process setting production process and integral rotating mechanism

A concrete block and wet process technology, which is applied in ceramic forming machines, ceramic forming workshops, manufacturing tools, etc., can solve the problems of increasing equipment investment, land use area and production costs, affecting the quality of fired bricks, and deformation of wet billets To achieve the effect of improving stacking speed and efficiency, ensuring stable clamping, and ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below through specific embodiments.

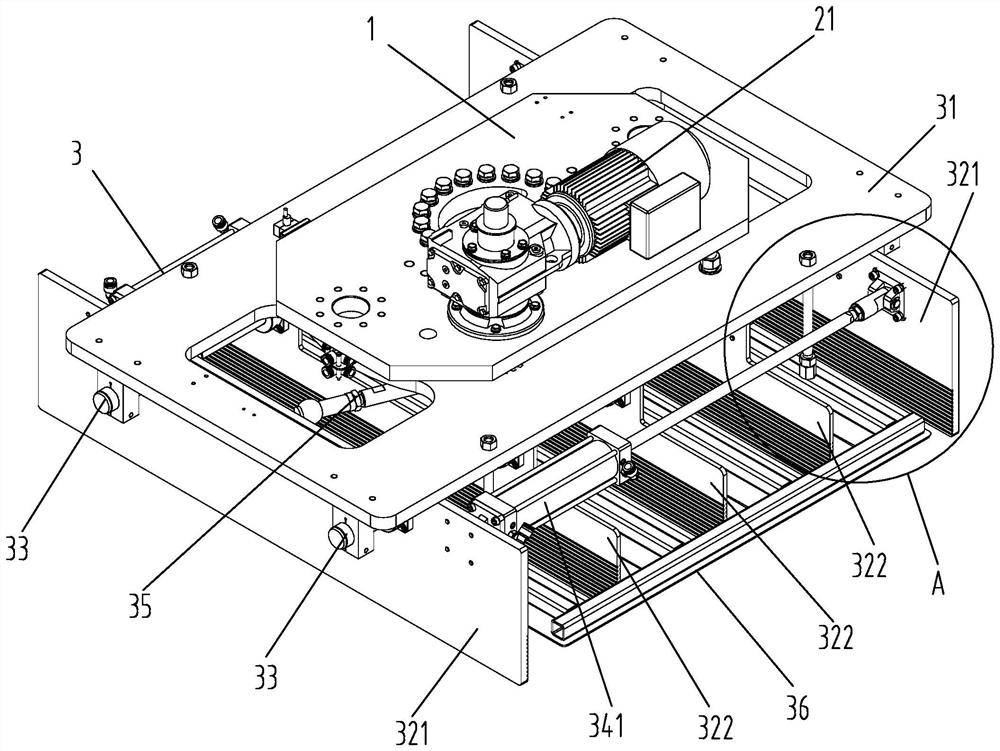

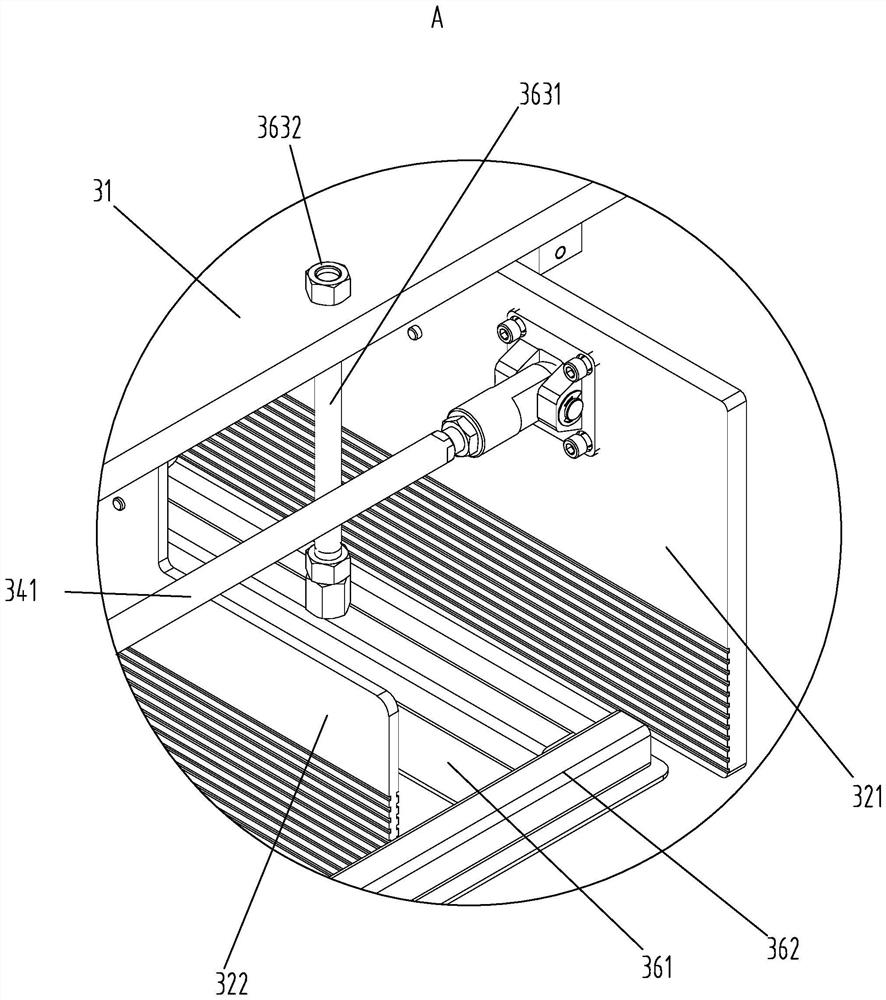

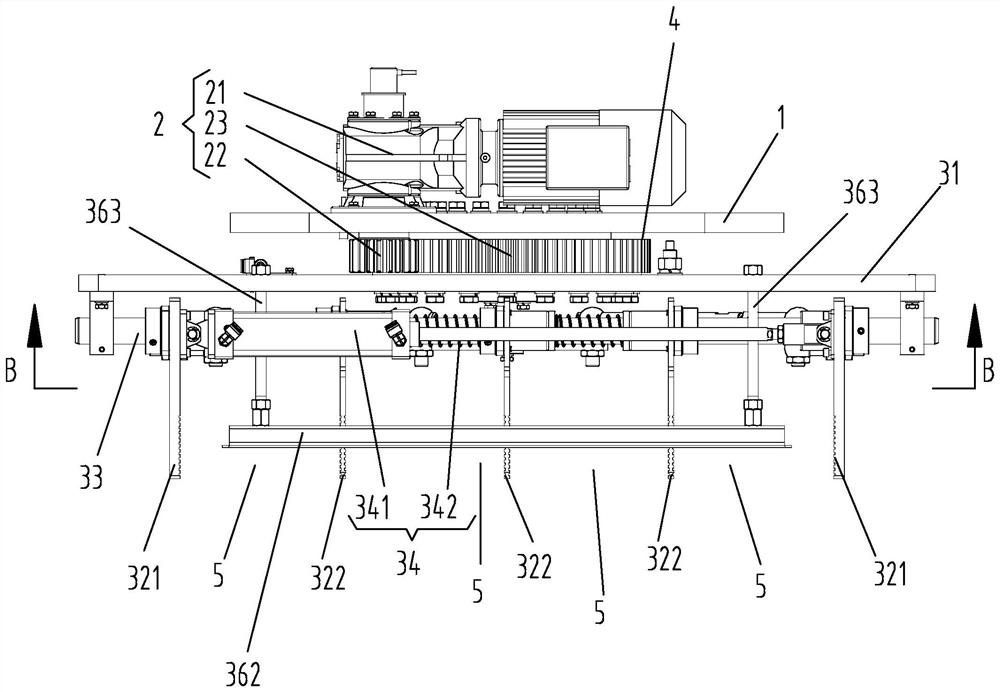

[0041] Such as Figure 9 Shown, a kind of concrete block forming wet process code blank production process of the present invention comprises the steps:

[0042] Step 1. The additives, water, cement, stones, sand and other raw materials are transported to the bottom material mixer after being measured;

[0043] Step 2. The base material mixer mixes and stirs the raw materials, and transports them to the concrete forming machine through the base material belt conveyor;

[0044] Step 3, the concrete forming machine forms the mixture and forms a wet concrete block;

[0045] Step 4. The three-coordinate wet-process code blank robot stacks the concrete block wet blank onto the wet blank stacking conveyor line;

[0046] Step 5. The forklift transports the wet concrete block stacked on the wet billet stacking conveyor line, and makes the wet concrete block undergo a new type of finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com