Measuring cup with automatic filling volume adjustment function

An automatic adjustment and measuring cup technology, applied in the field of measuring cups, can solve the problems of affecting product cleaning, polluting the working environment, and non-adjustable volume, and achieves the effects of simplifying the replacement process, improving production efficiency, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

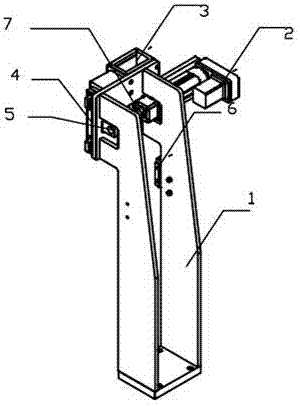

[0017] As a preferred embodiment of the present invention, the control panel (6) includes a touch screen, and the touch screen is provided with the enlargement and reduction buttons of the measuring cup, which can also directly input the target volume to make the stepping electric cylinder automatically Adjustment.

[0018] When working, adjust the movement of the stepping electric cylinder (2) through the touch screen of the control panel (6), and the stepping electric cylinder (2) drags the lateral movement of the measuring cup telescopic block (4) through the transmission rod, thereby controlling the measuring cup (3 ) volume size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com