Track-type lifting and transferring robot for circuit board production

A circuit board and track-type technology, which is applied in the field of track-type lifting and transferring robots for circuit board production, can solve the problems of labor and material resources, low work efficiency, etc., and achieve the effect of long service life, extended service life and smooth contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

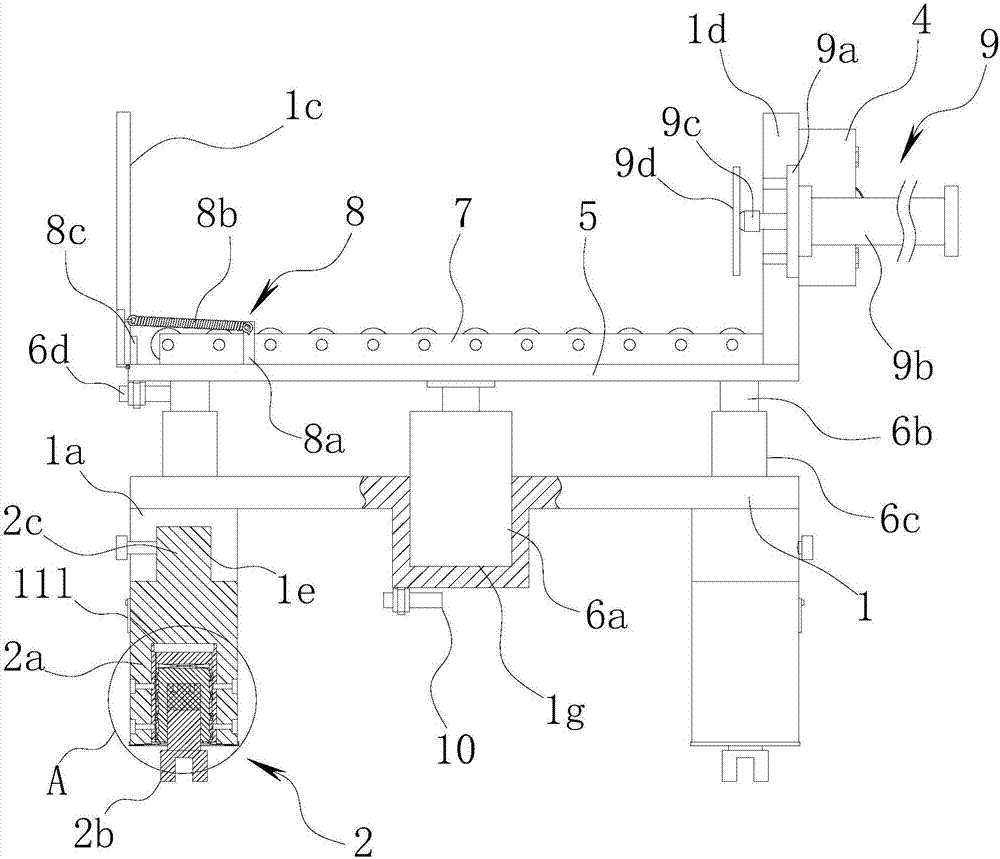

[0028] refer to Figure 1 to Figure 6 As shown, a track-type lifting transfer robot for circuit board production of the present invention includes an installation platform 1, and two front mounting seats 1a and two rear installation seats 1a that cooperate with each other are respectively provided at the four corners of the lower end surface of the installation platform 1. Seat 1b, the lower ends of the two front mounts 1a are respectively provided with driven sliding devices 2 adapted to the rails, and the lower ends of the two rear mounts 1b are respectively provided with active sliding devices 3 adapted to the rails, and the active sliding devices 3 A main control unit 4 is connected.

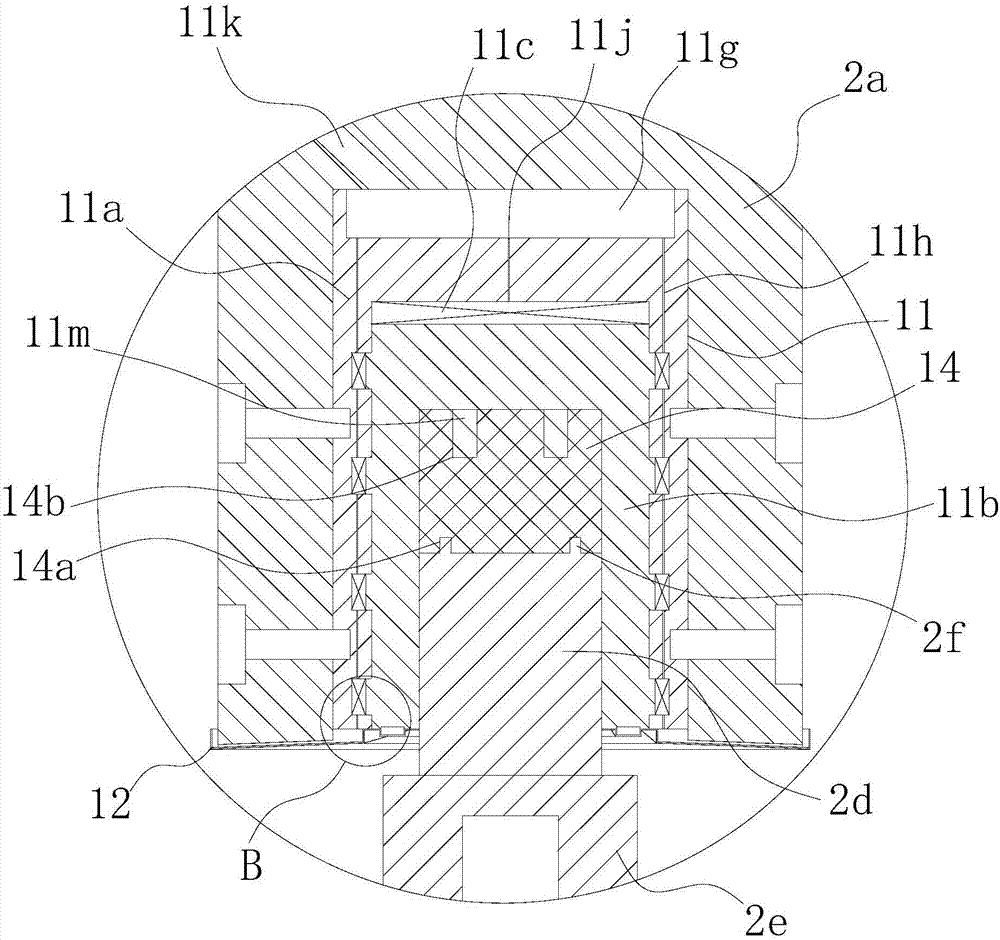

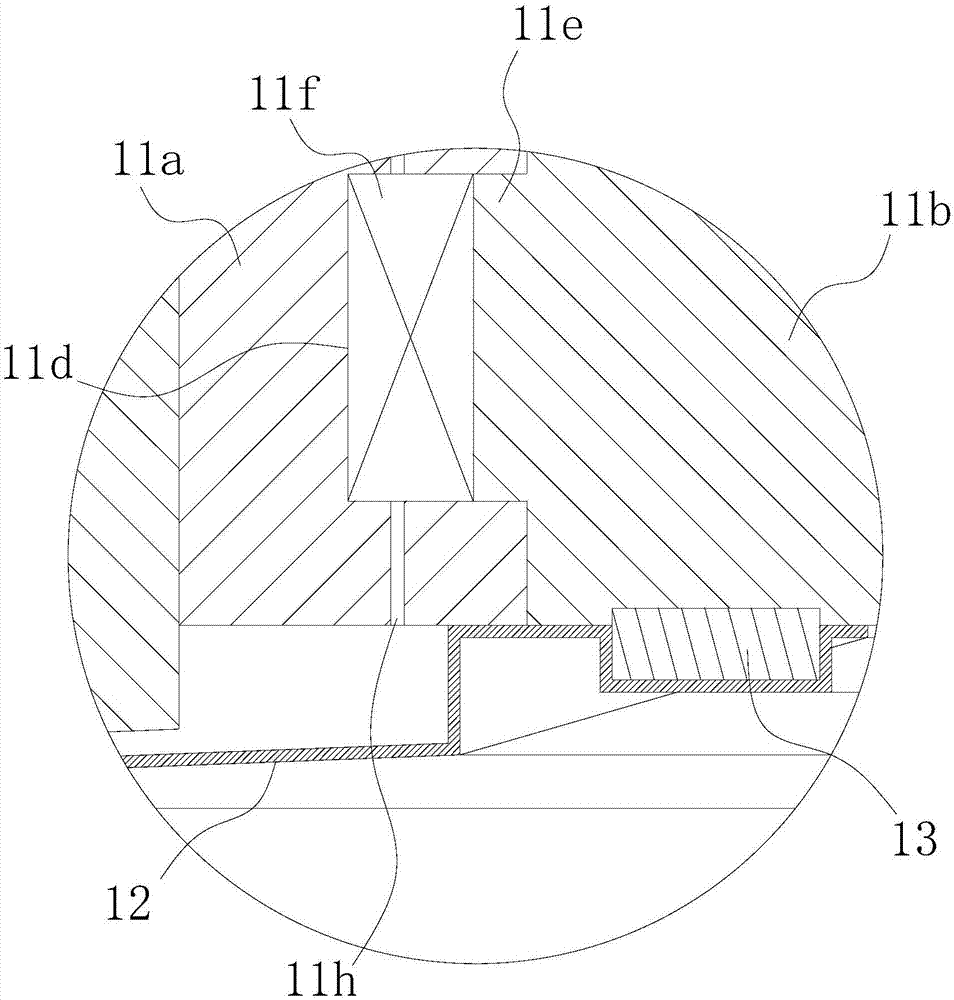

[0029] Specifically, see figure 2 and image 3 As shown, the driven sliding device 2 is composed of a connecting seat 2a open on one side, a horizontal rotator 11 sleeved in the inner hole of the connecting seat 2a, and a wear-resistant rotator inserted in the horizontal rotator 11 and matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com