A circuit board transfer robot

A technology of robots and circuit boards, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of manpower and material resources, low work efficiency, etc., and achieve long service life, extended service life, and smooth sliding steering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

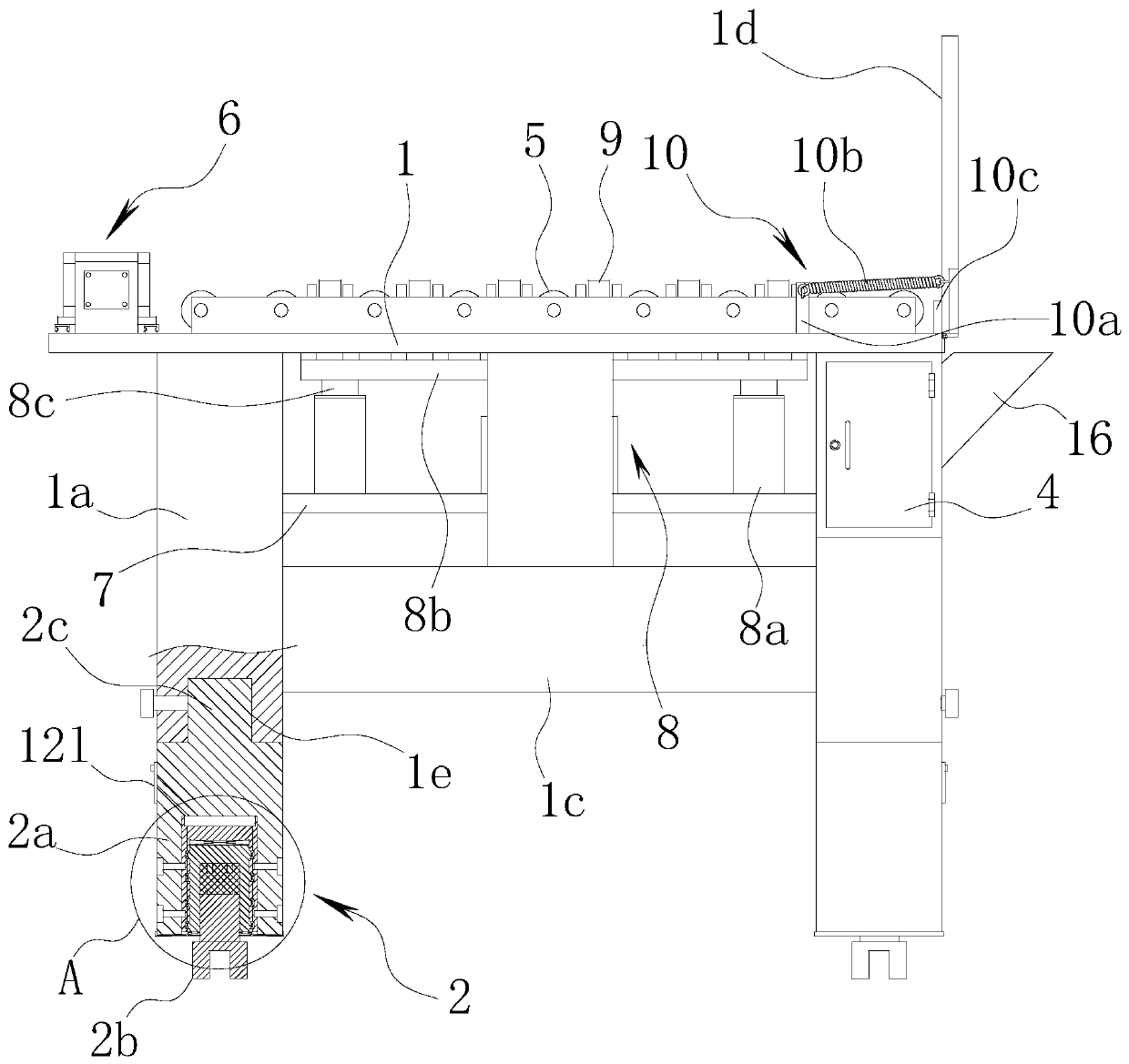

[0034] refer to Figure 1 to Figure 8 As shown, a circuit board transfer robot of the present invention includes a square installation platform 1, and two front columns 1a and two rear columns 1b that cooperate with each other are respectively provided at the four corners of the lower end surface of the installation platform 1. A positioning link 1c is arranged between a front column 1a, two rear columns 1b and adjacent front columns 1a and rear columns 1b, and a driven sliding device 2 adapted to the track is respectively provided at the lower ends of the two front columns 1a. , the lower ends of the two rear columns 1b are respectively provided with an active sliding device 3 adapted to the track, and the active sliding device 3 is connected with a main control unit 4 .

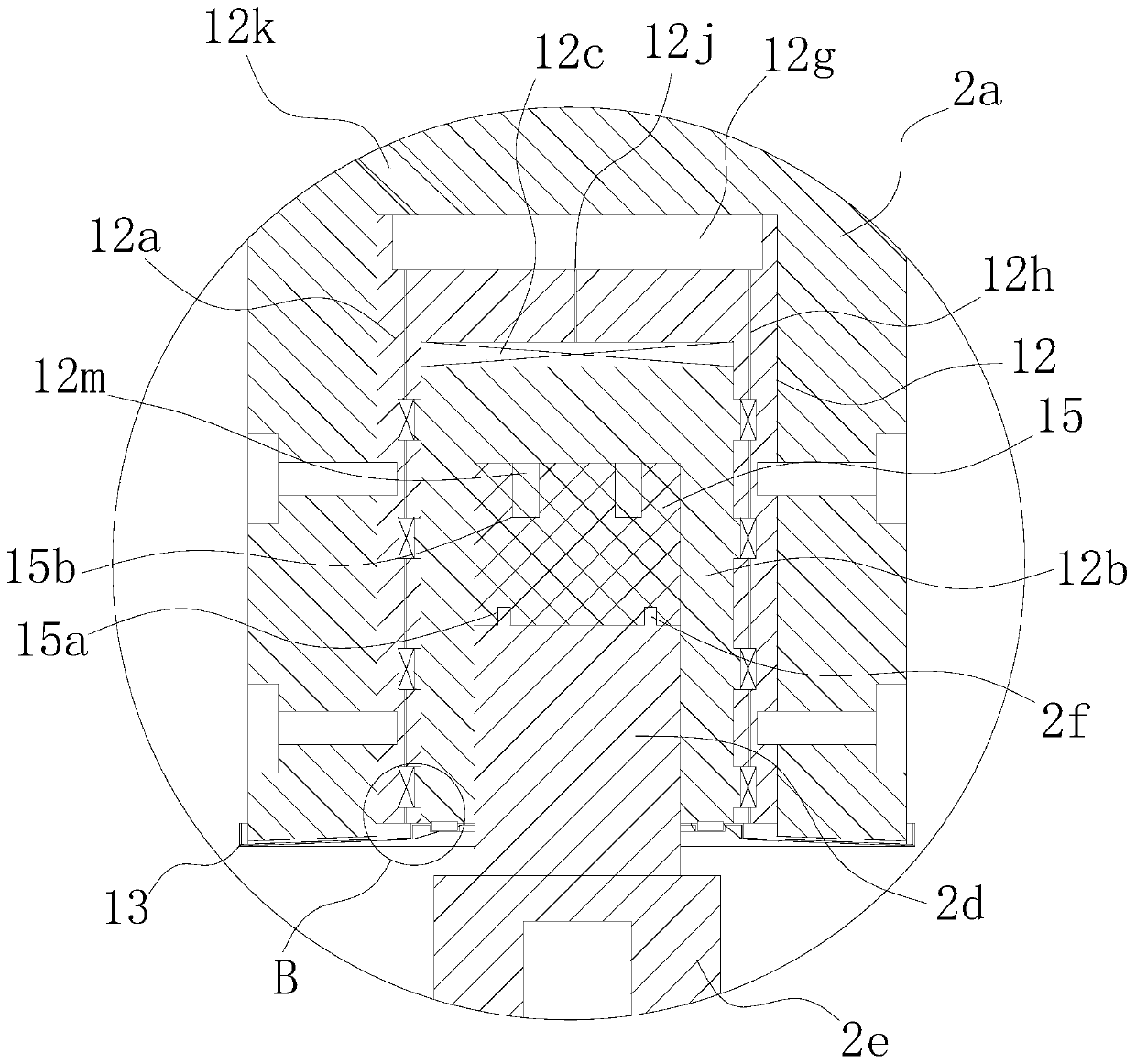

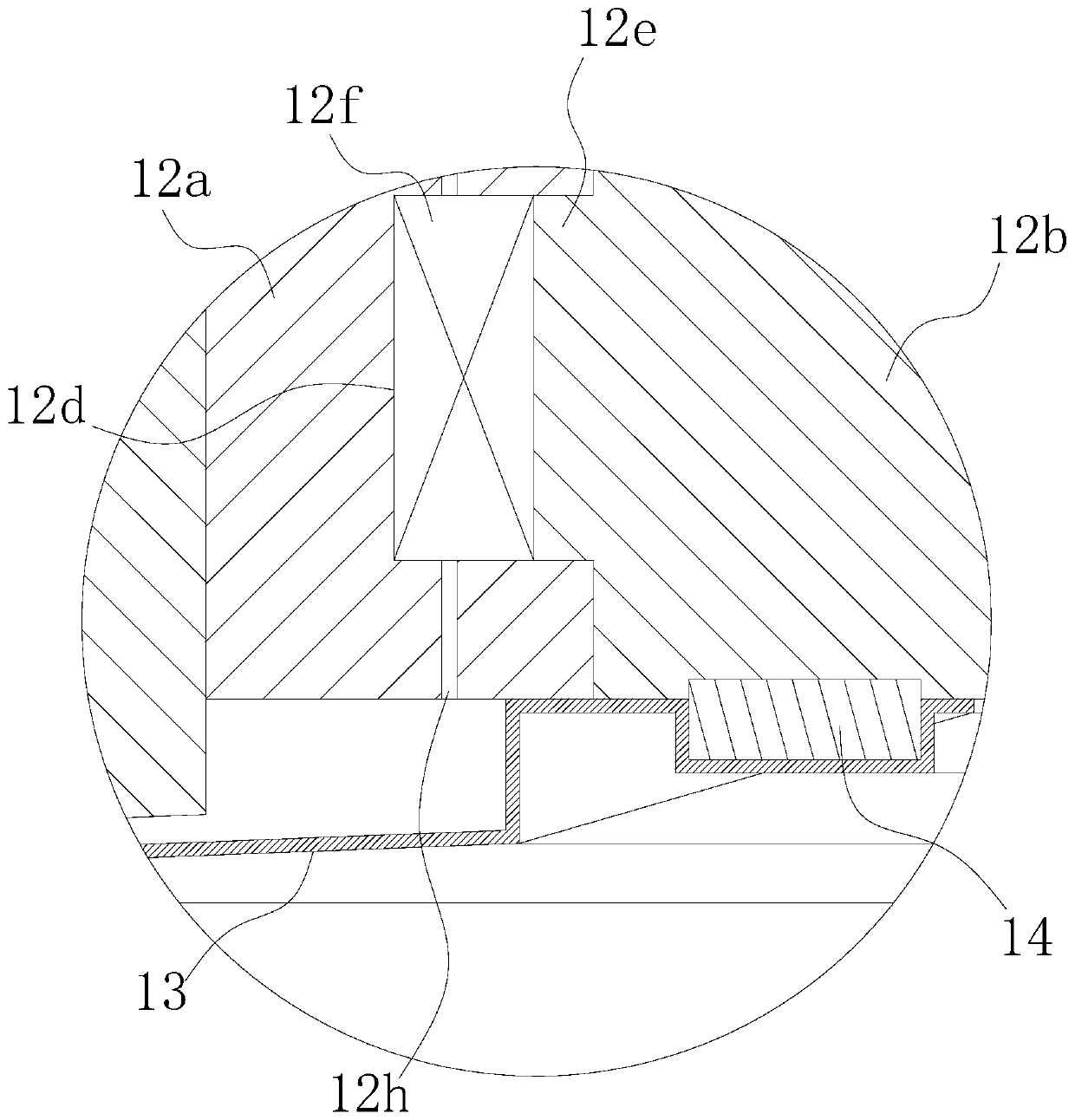

[0035] Specifically, see figure 2 with image 3 As shown, the driven sliding device 2 is composed of a connecting seat 2a open on one side, a horizontal rotator 12 sleeved in the inner hole of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com