Forklift lifting chain seat

A chain seat and forklift technology, applied in the direction of lifting devices, etc., can solve problems affecting product quality, affecting production efficiency, and increasing production costs, and achieve the effects of avoiding thermal deformation, improving quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

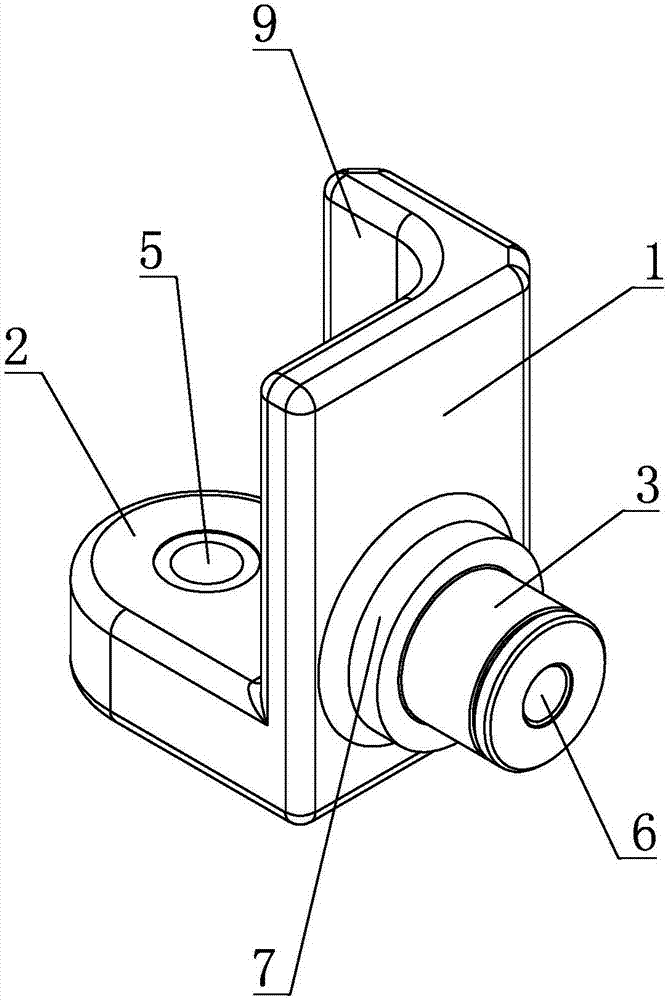

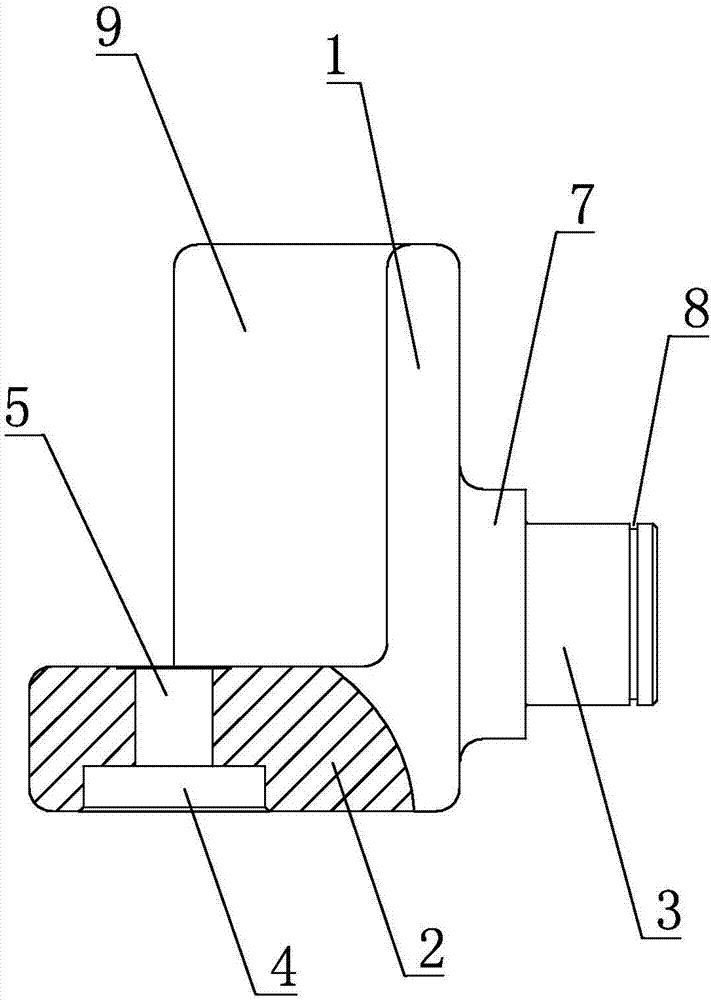

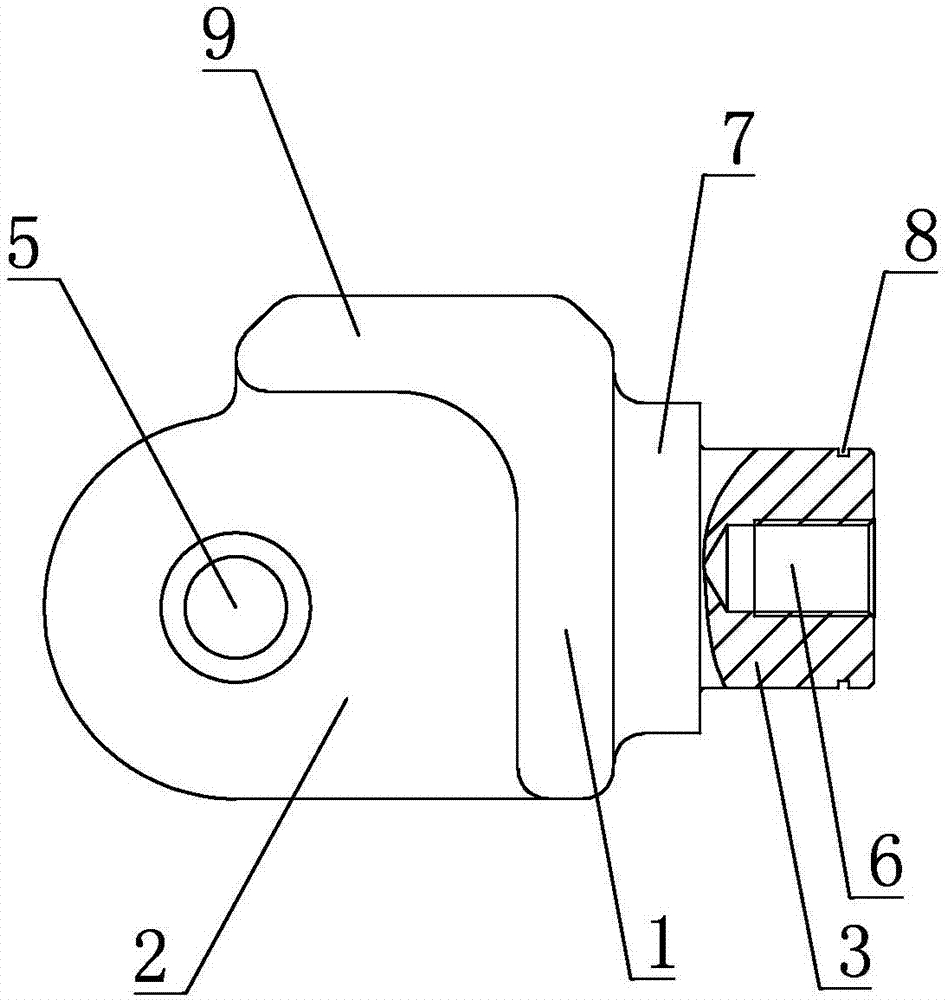

[0015] refer to Figure 1 to Figure 3 , a forklift lifting chain seat is characterized in that: it includes a rectangular sprocket seat plate 1, a cylinder head seat plate 2 perpendicular to it is provided on the lower end side of the sprocket seat plate 1, and a sprocket seat plate 1 is provided on the outside The sprocket hub 3, the sprocket seat plate 1, the cylinder head seat plate 2 and the sprocket hub 3 are integrally cast from cast steel. By integrating the original sprocket seat, the left and right cylinder head seats and the sprocket shaft head into a cast steel piece, and fixing them symmetrically on the lower sides of the two ends of the upper beam from left to right, reducing and eliminating the damage caused by blanking Material loss reduces production costs, avoids the disadvantages of thermal deformation caused by large-area welding and the workpiece is easily damaged from the weld, and greatly improves the quality of the product; the process of welding and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com