High-efficiency production line for tempered glass pot lids

A production line, tempered glass technology, applied in glass production, glass tempering, glass manufacturing equipment and other directions, can solve problems such as poor production efficiency and difficult to guarantee quality, and achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

[0027] The definition of relevant direction of the present invention is to be defined according to the direction that tempered glass pot cover is transported.

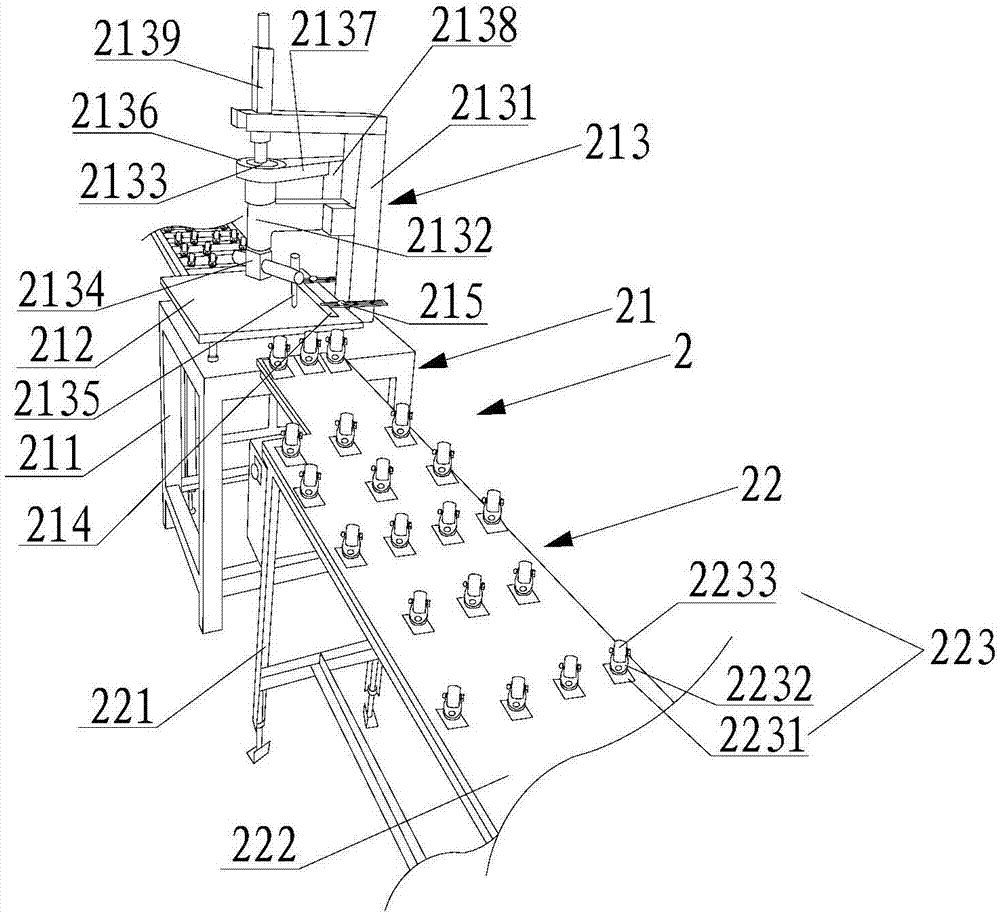

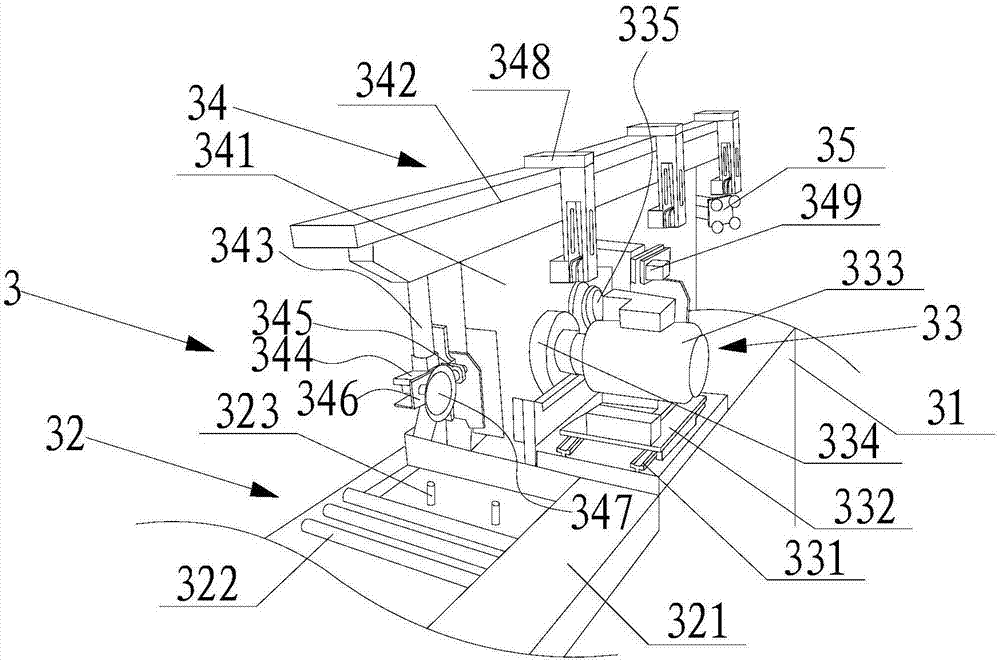

[0028] The high-efficiency tempered glass pot lid production line of the present invention mainly includes a raw material frame 1, a wafer cutting device 2, a grinding device 3, a cleaning device 4, a heating feeding system 5, and a cooling assembly 6 arranged in sequence.

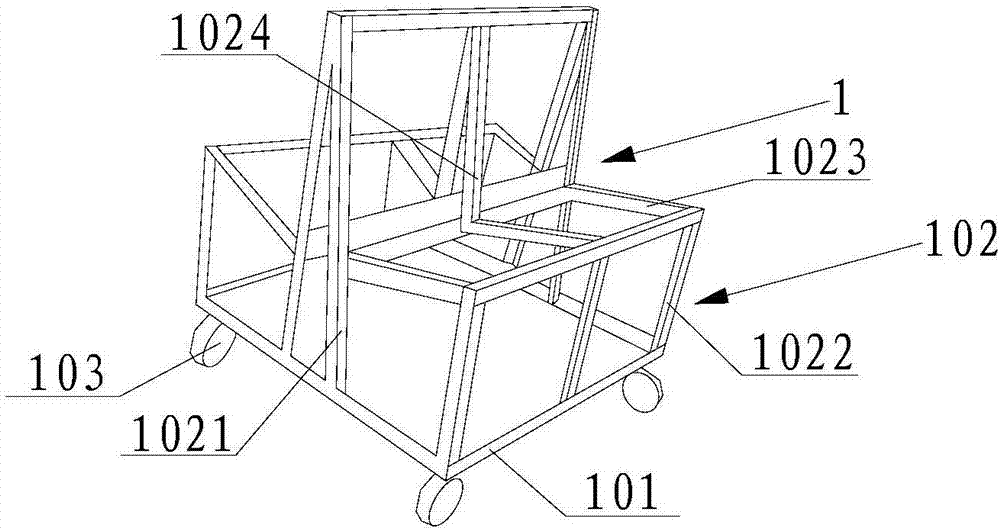

[0029] Such as figure 1 The raw material rack body 1 shown is used for placing tempered glass pieces; it mainly includes a first bottom frame 101 , a shelf 102 and a first roller 103 . Wherein, the first bottom frame 101 is arranged horizontally, and a plurality of first rollers 103 are installed on its bottom. There are two groups of storage racks 102, which are installed on the upper surface of the first bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com