Large curtain wall vertical shading system

A curtain wall and vertical technology, which is applied in the field of large-scale curtain wall vertical sunshade system, can solve the problems that the sunshade reduces the overall structural stability, increases the wind resistance of the sunshade system, and peels off the sunshade, so as to avoid the rise of indoor temperature and save the amount of materials , Anti-glare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

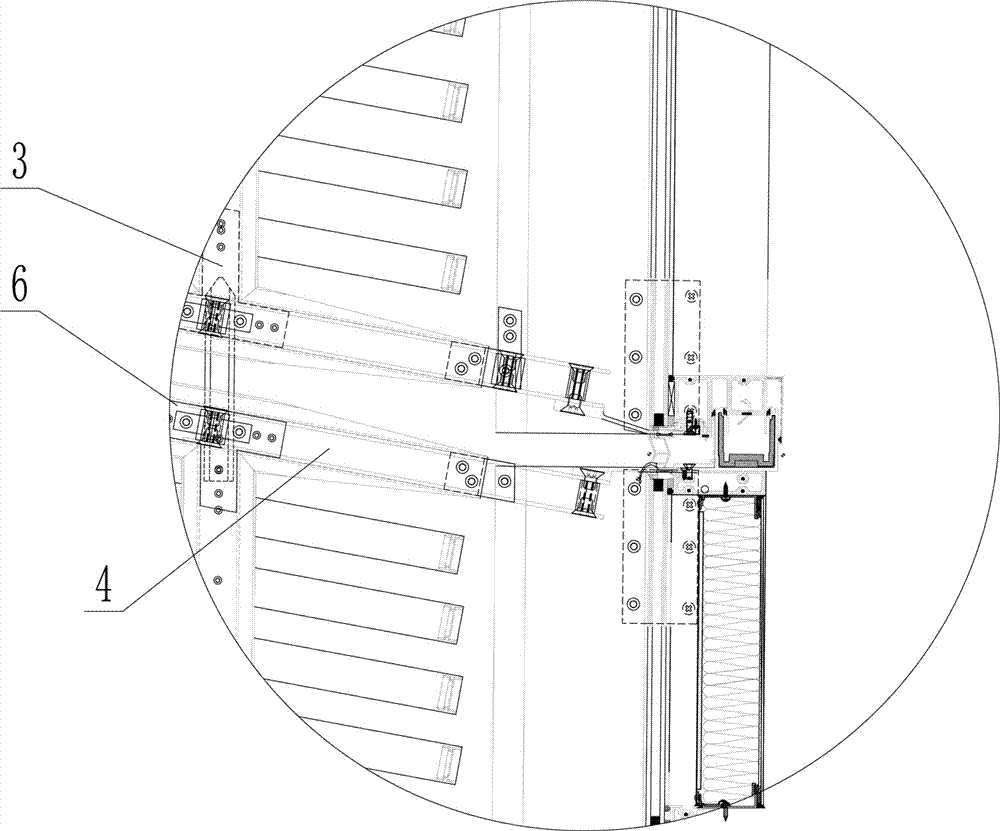

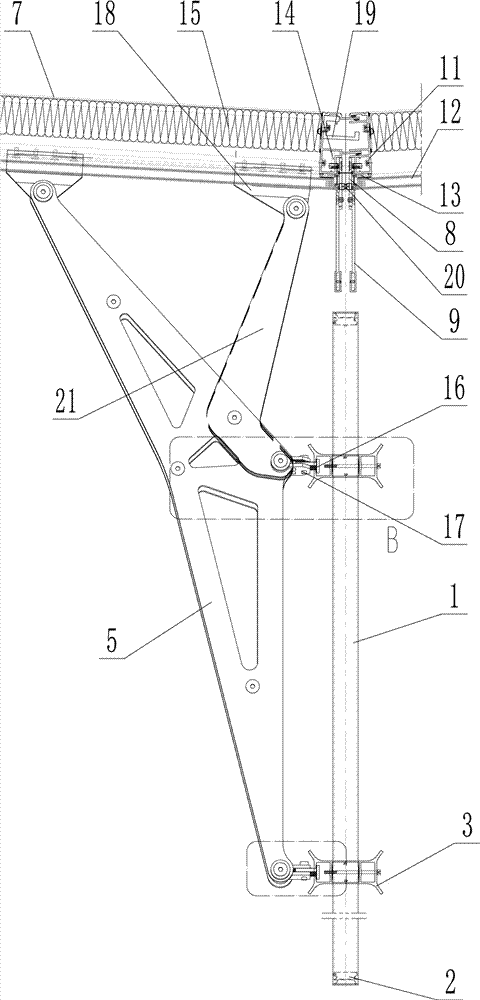

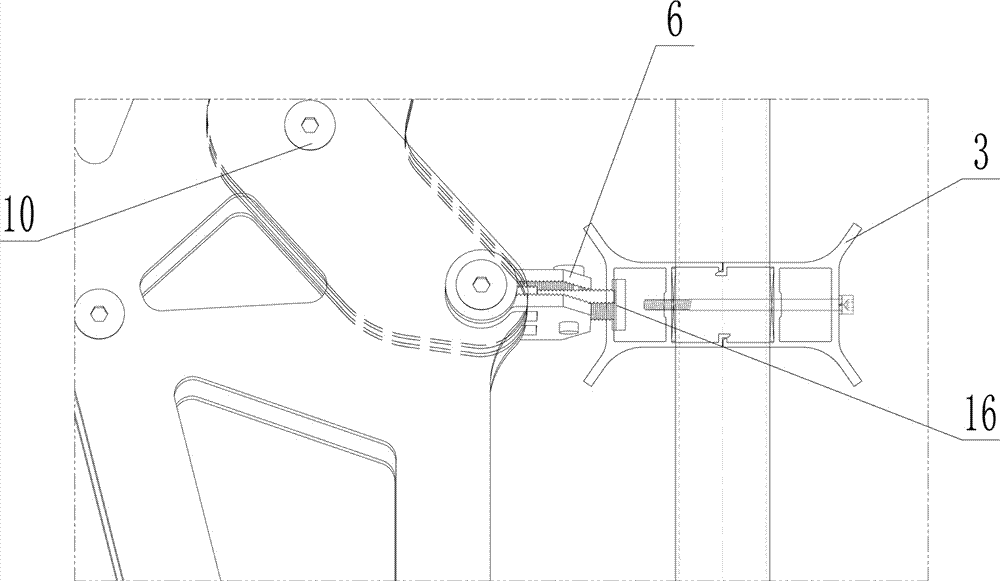

[0023] The following combination Figure 1~7 , the content of the present invention will be described in detail through specific embodiments. The large curtain wall vertical sunshade system includes more than one sunshade unit, and each sunshade unit includes a support assembly assembled outside the curtain wall and a sunshade assembly assembled on the support assembly. Among them, the curtain wall can adopt the existing structure, such as the protective layer 7 arranged in sequence from the inside to the outside (used to waterproof and dustproof the indoor thermal insulation layer to improve its service life), thermal insulation layer 15, glass 12 (glass usually Double-layer glass can be used and fixed by sealant 13), the adjacent curtain wall glass is connected to each other through the middle stile 11 composed of mother and daughter parts, and can be adjusted at a small angle, and the middle stile 11 is provided with reinforcements 19 and reinforcement ribs 14 to improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com