Measurement-while-drilling exploring tube device used for mining

A measurement-while-drilling and mine-used technology, which is applied in the direction of measurement, drill pipe, drill pipe, etc., can solve the problems of complex probe pipe structure and poor reliability, and achieve the effects of shortening the length of the probe pipe, reliable connection, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

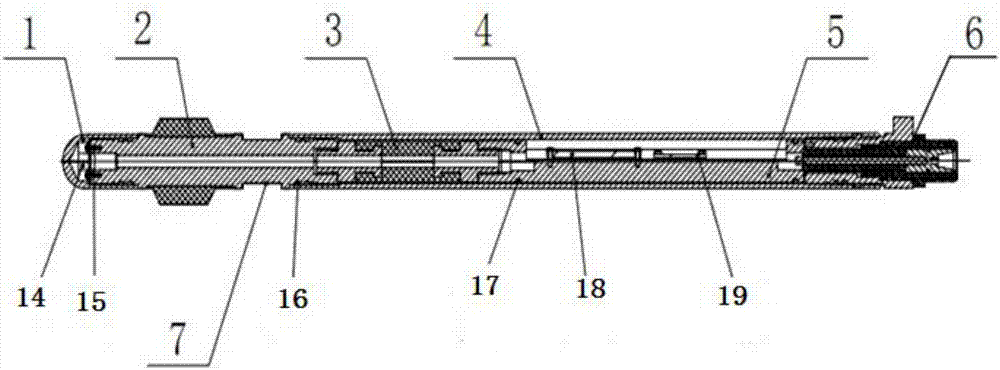

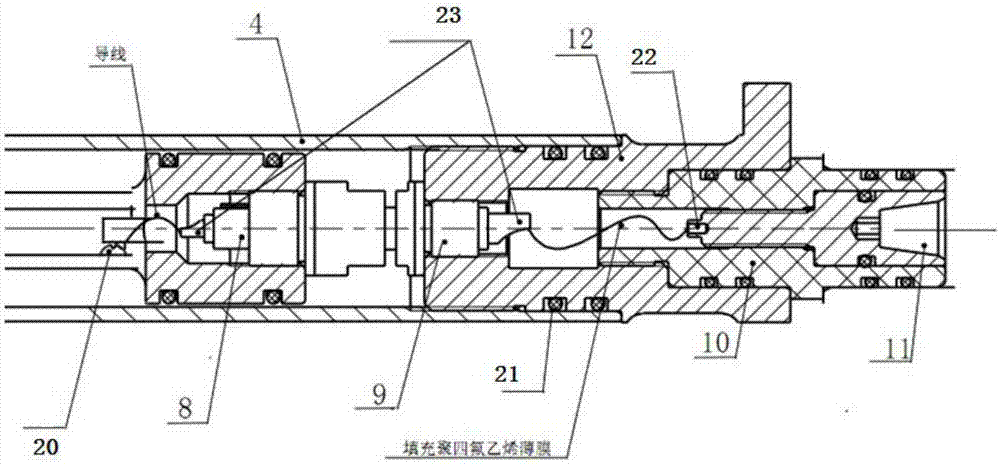

[0042] This embodiment relates to a mine-used measuring-while-drilling probe device, see attached figure 1 , 2 . The front end of the support assembly is threadedly connected to the end cover part 1;

[0043] The shock absorber assembly 3 is threadedly installed in the threaded hole of the central axis at the rear end of the support assembly;

[0044] One end of the outer tube 4 is threadedly mounted on the rear end of the support assembly; the jack column assembly 6 is threadedly mounted on the other end of the outer tube 4;

[0045] The base assembly 5 is threadedly installed on the rear end core connector of the shock absorber assembly 3 .

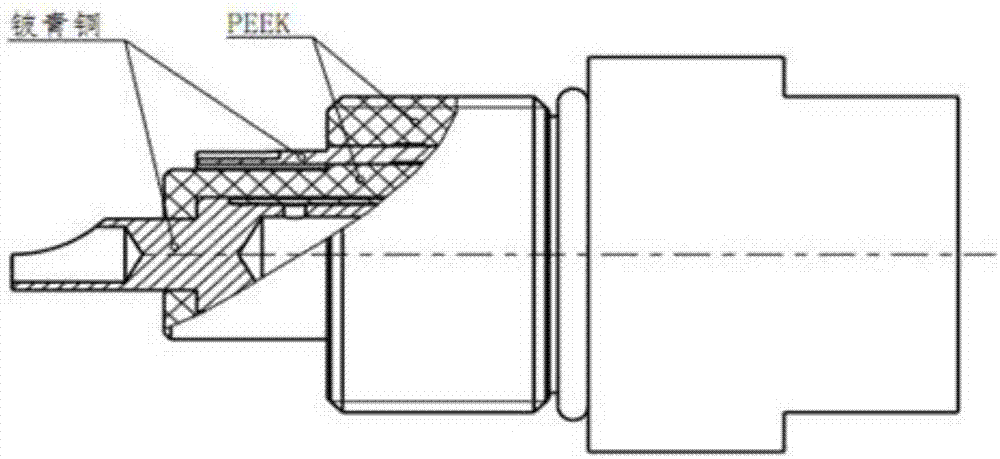

[0046] Further, the support assembly is composed of a seven-pin connector socket 14, a plug part 7 and a four-wing centralizer part 2, and the seven-pin connector socket 14 is screw-mounted on the top of the front section of the plug part 7, so that The four-wing centralizer part 2 is sheathed on the plug part 7.

[0047] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com