Comprehensive gas drainage arrangement treatment method for quick extraction of gas on fully-mechanized surface

A fully-mechanized mining face and gas technology, which is applied in the field of gas comprehensive drainage and management of rapid recovery fully-mechanized mining face, can solve the problems of difficulty in gas management, danger of gas exceeding the limit, and gas exceeding the limit, so as to eliminate the situation of drainage drilling , good support conditions and sufficient working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

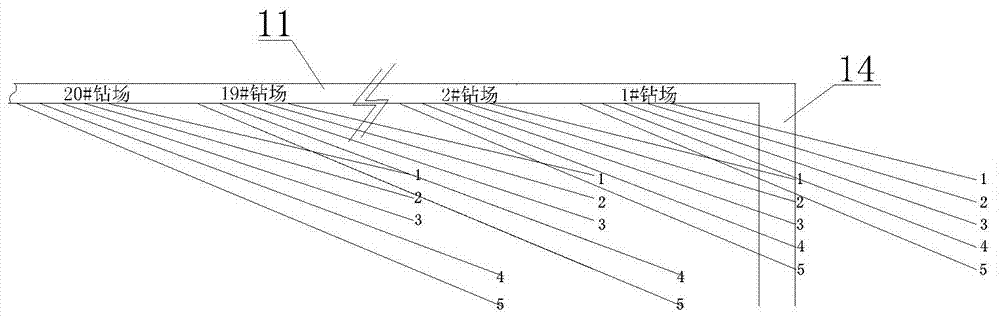

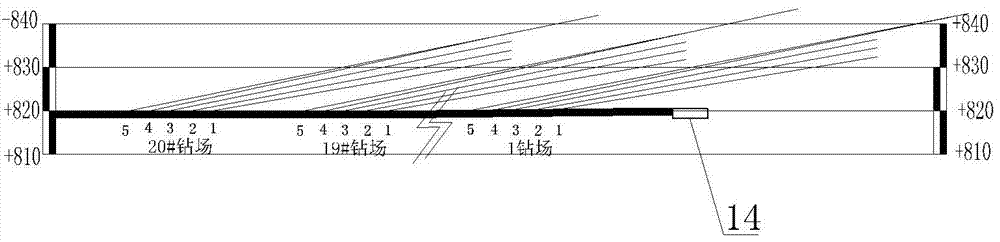

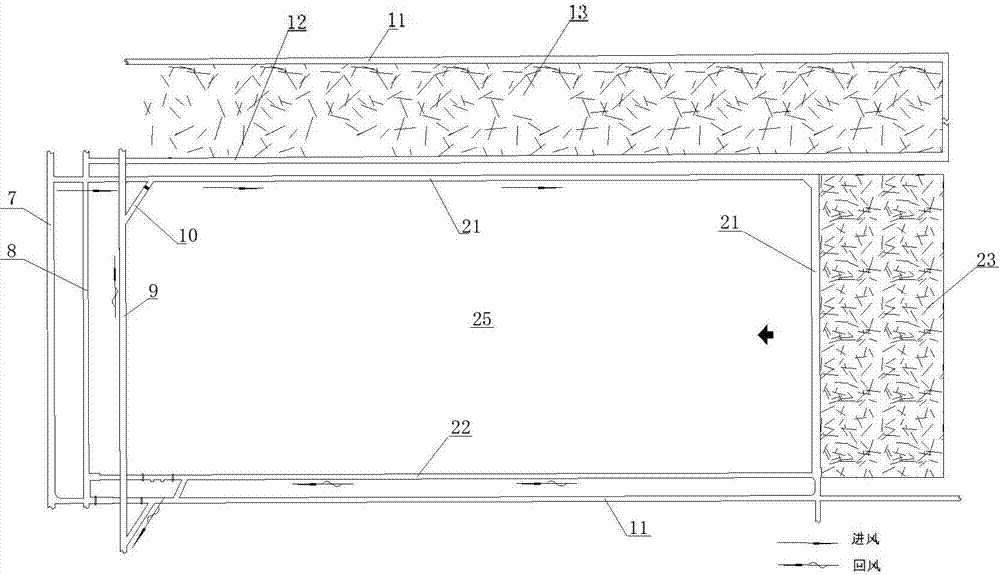

[0021] see Figure 3-Figure 7 , New adjustments have been made in the excavation layout, ventilation mode, and drainage method of the 106 fully mechanized mining face. The specific methods adopted for the mining space layout and gas control of the 106 fully mechanized mining face are as follows:

[0022] Working face 106 has a strike length of 2,400 m, an inclination width of 245 m, and delineated reserves of 1.3 million tons. According to the drainage situation of the previous working face, the gas concentration and scalar volume of the high-level cracks on the roof are high, and the gas gushing out of the goaf is large. The overall idea of gas management is adjusted to: use large drilling rigs to construct large-aperture and high-density drilling holes, increase the drainage of high-level cracks in the roof, and increase the drainage of gobs. When the working face is mined back, it is affected by coal belt racks, materials, equipment trains, electrical equipment, etc., and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com