Combined tube, combined tube assembly and evaporating and cooling equipment

A combined tube and cooling water technology, applied in lighting and heating equipment, machines using refrigerant evaporation, refrigerators, etc., can solve the problems of uneven distribution of water film, low cooling efficiency, large water consumption, etc., to save electricity and water consumption, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

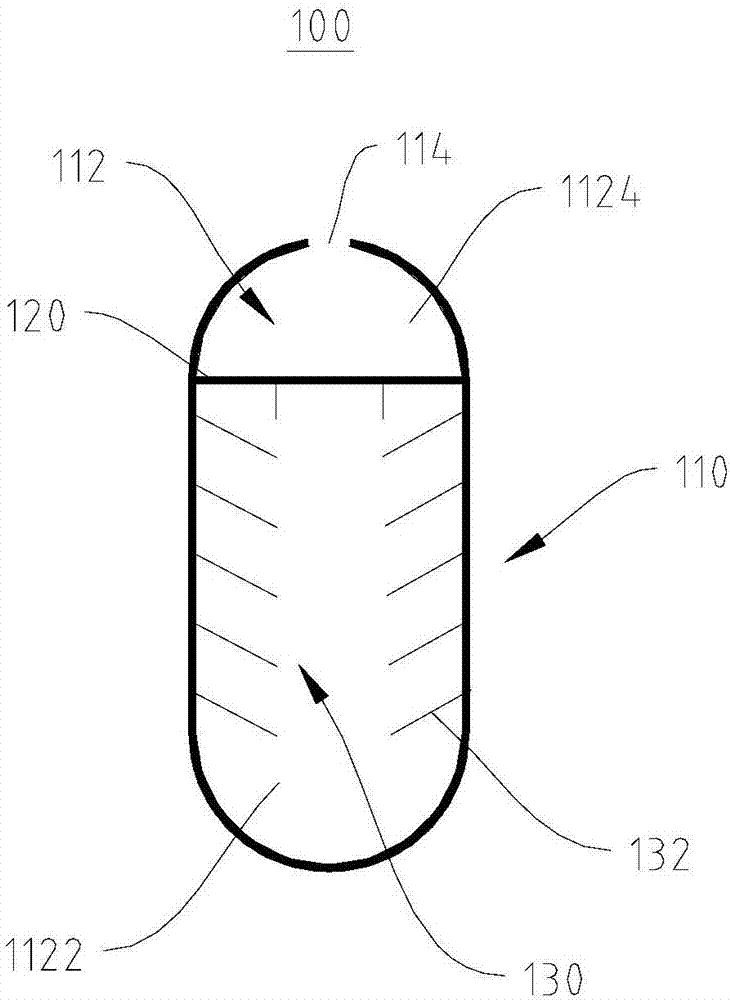

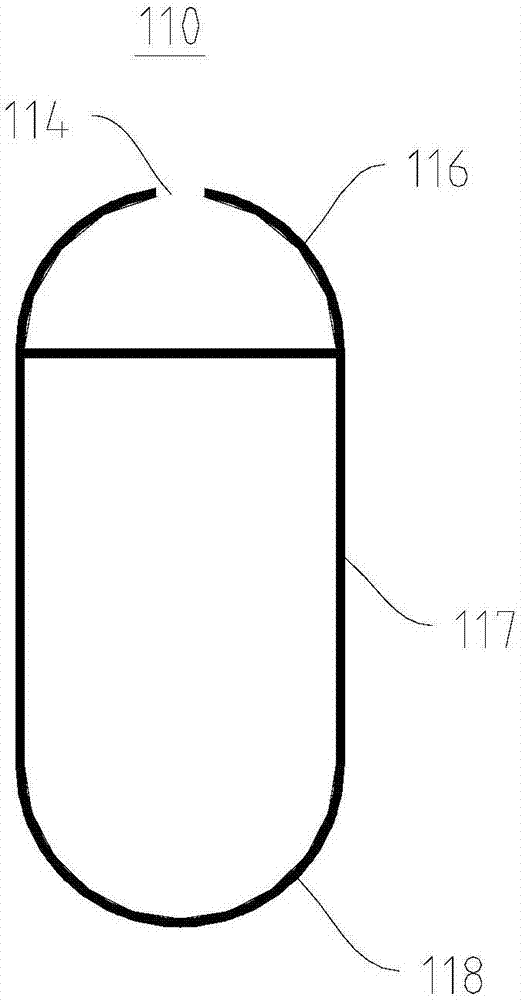

[0032] see figure 1 , this embodiment provides a combined pipe 100, the combined pipe 100 provided in this embodiment improves the utilization rate of the combined pipe 100 and saves space.

[0033] In this embodiment, the combined tube 100 includes a tube body 110, a partition 120, and a heat dissipation assembly 130. The tube body 110 has an accommodating cavity 112, and the partition 120 divides the accommodating cavity 112 into a first sub-accommodating cavity 1122 and a second sub-accommodating cavity 1122. Two sub-accommodating chambers 1124, the first sub-accommodating chamber 1122 is used to accommodate the cooled fluid, the second sub-accommodating chamber 1124 is used to accommodate cooling water, and the connecting pipe connects the second of two adjacent combined pipes 100. The sub-accommodating cavity 1124 . The heat dissipation assembly 130 is disposed in the first sub-accommodating chamber 1122 and connected to the inner sidewall of the tube body 110 .

[0034...

Embodiment 2

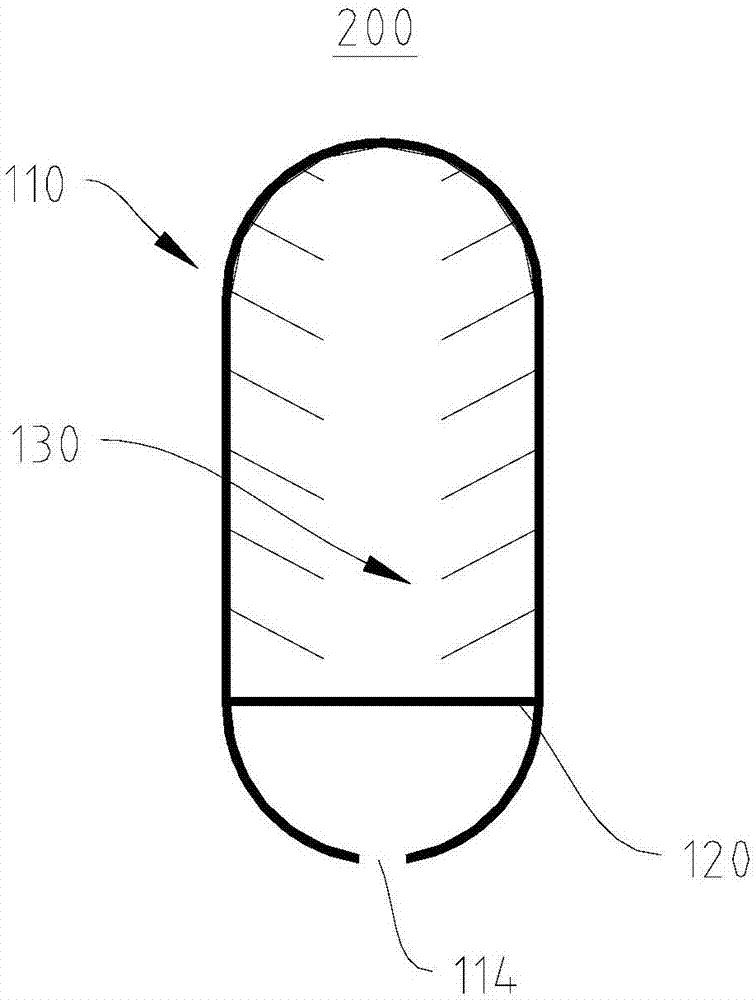

[0048] see image 3 , the combined pipe 200 provided in this embodiment, the combined pipe 200 provided in this embodiment improves the utilization rate of the combined pipe 200 and saves space.

[0049] The combined pipe 200 provided in this embodiment has the same basic structure and principle as well as the technical effects produced in the first embodiment. For brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0050] The difference between the combination tube 200 provided in this embodiment and the first embodiment is that in this embodiment, the heat dissipation ribs 132 are arranged in a direction close to the partition plate 120 .

[0051] In this embodiment, when the combined pipe 200 is in working condition, the first sub-accommodation chamber 1122 is located above the second sub-accommodation chamber 1124 , and when the cooling water in the pipe body 110 flows from the second ...

Embodiment 3

[0053] see Figure 4 , the combined pipe assembly 10 provided in this embodiment, the combined pipe assembly 10 provided in this embodiment improves the utilization rate of the combined pipe assembly 10 and saves space.

[0054] For a brief description, reference may be made to Embodiment 1 and Embodiment 2 for the parts not mentioned in this embodiment.

[0055] In this embodiment, the combined tube assembly 10 includes a plurality of connecting tubes 300 and a plurality of combined tubes 100 , and the connecting tubes 300 connect two adjacent combined tubes 200 .

[0056] It should be noted that the combined tube assembly 10 may include the combined tube 100 in the first embodiment, or the combined tube 200 in the second embodiment. This embodiment takes the combined tube 100 in the first embodiment as an example for specific description.

[0057] In this embodiment, the connecting pipe 300 communicates with the second sub-accommodating chambers 1124 of two adjacent combina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com