Fatigue life tester of dynamic load of working ladder of military aircraft

A dynamic load and fatigue life technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve the fatigue and service life management of ladder structures, cannot effectively guarantee the safety of ladder use, and is not used for testing Ladder fatigue life technology and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

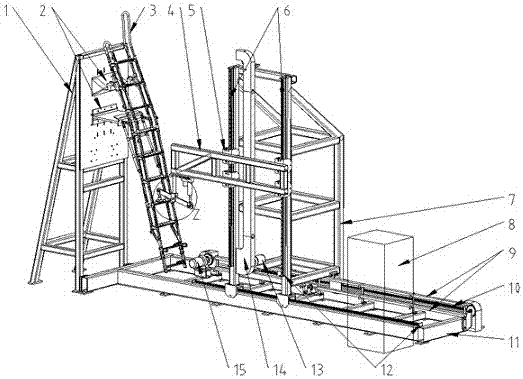

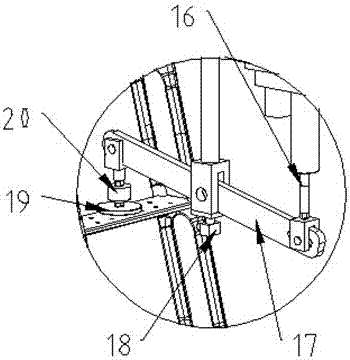

[0011] exist figure 1 , figure 2 Among them, the present invention is provided with a ladder hanger 1, and a fixed frame 11 is installed on one side of the ladder hanger 1, and a horizontal slide rail 10 is arranged on both sides of the fixed frame 11, and a horizontally movable frame 7 is installed on the horizontal slide rail 10, and the horizontally movable The frame 7 is controlled by the horizontal frequency conversion motor 15, the horizontal gear chain 9, and the limit block 12 to move laterally on the horizontal slide rail 10; Movable frame 4, vertically movable frame 4 is controlled by longitudinal variable frequency motor 13, longitudinal gear chain 14, positioning block 5 to move longitudinally on the longitudinal slide rail 6; the lower side of the front end of longitudinally movable frame 4 is hinged with the middle part of loading lever 17, and the loading lever 17 rear end is hinged with electric push rod 16, loading head 19 is installed on the front end of lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com