DSP remote debugging device and method based on serial communication

A technology of remote debugging and serial communication, which is applied in the direction of program control, general control system, electrical testing/monitoring, etc., and can solve the problem that remote debugging and data recording cannot be completed, program variable changes cannot be recorded, and debuggers cannot debug on site And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

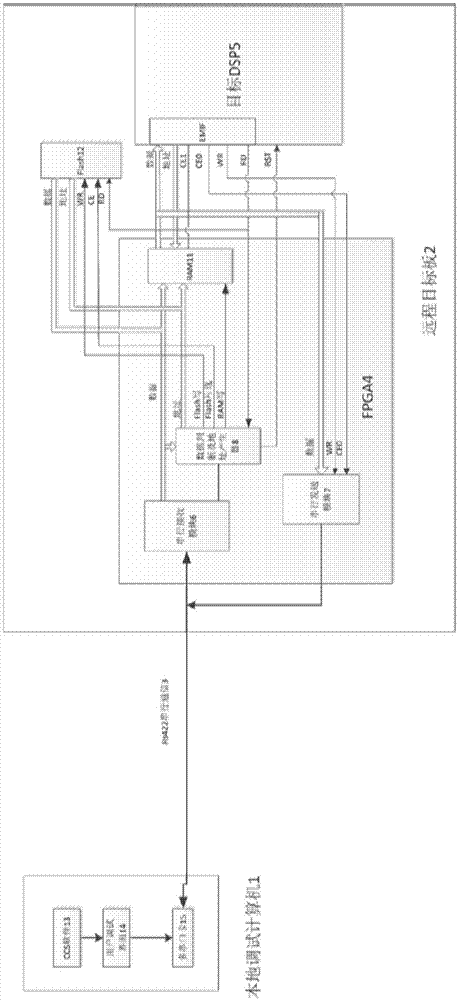

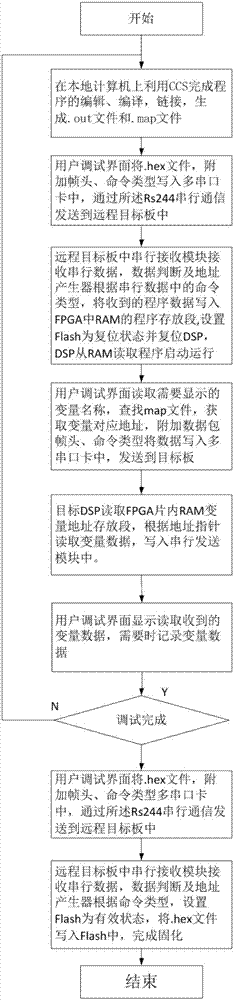

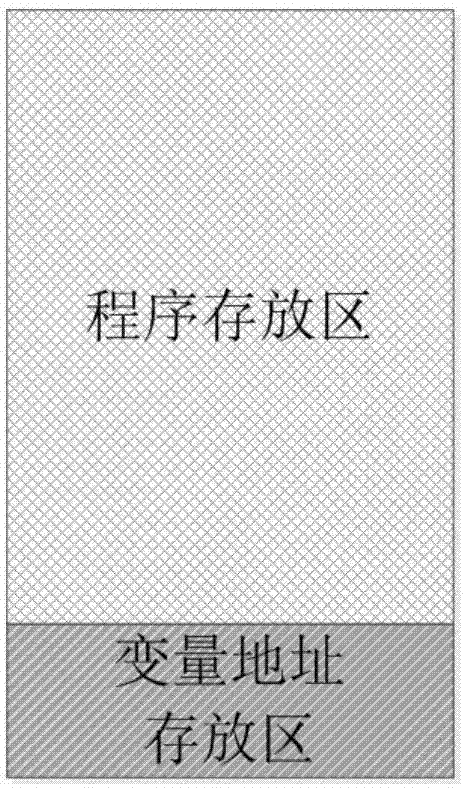

[0056] Such as figure 1 Shown, a kind of DSP debugging method based on serial communication of the present invention, hardware comprises: local debugging computer 1, remote target board 2, RS422 serial communication bus 3; Described remote target board 2 comprises FPGA 4, Flash program memory 12 and DSP 5; the internal logic of the FPGA 4 includes a serial receiving module 6, a serial sending module 7, a data judgment and address generating module 8, and a program storage dual-port RAM11. The local debugging computer 1 includes a software integrated development environment CCS13, a multi-serial port card 15 and a user debugging interface 14. The multi-serial port card 15 is connected with the remote target board 2 through the RS422 serial communication bus 3 to complete two-way RS422 communication. The local debugging computer 1 includes an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com