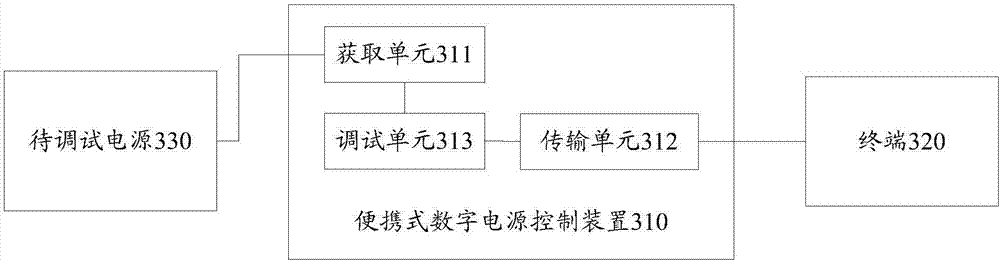

Digital power control method, device and system

A technology of digital power supply and control device, applied in the direction of output power conversion device, electrical components, etc., can solve the problems of reducing debugging efficiency, reducing product quality control, increasing the complexity and workload of power supply design, and improving portability. and efficiency, improve the efficiency of debugging, and realize the effect of remote debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

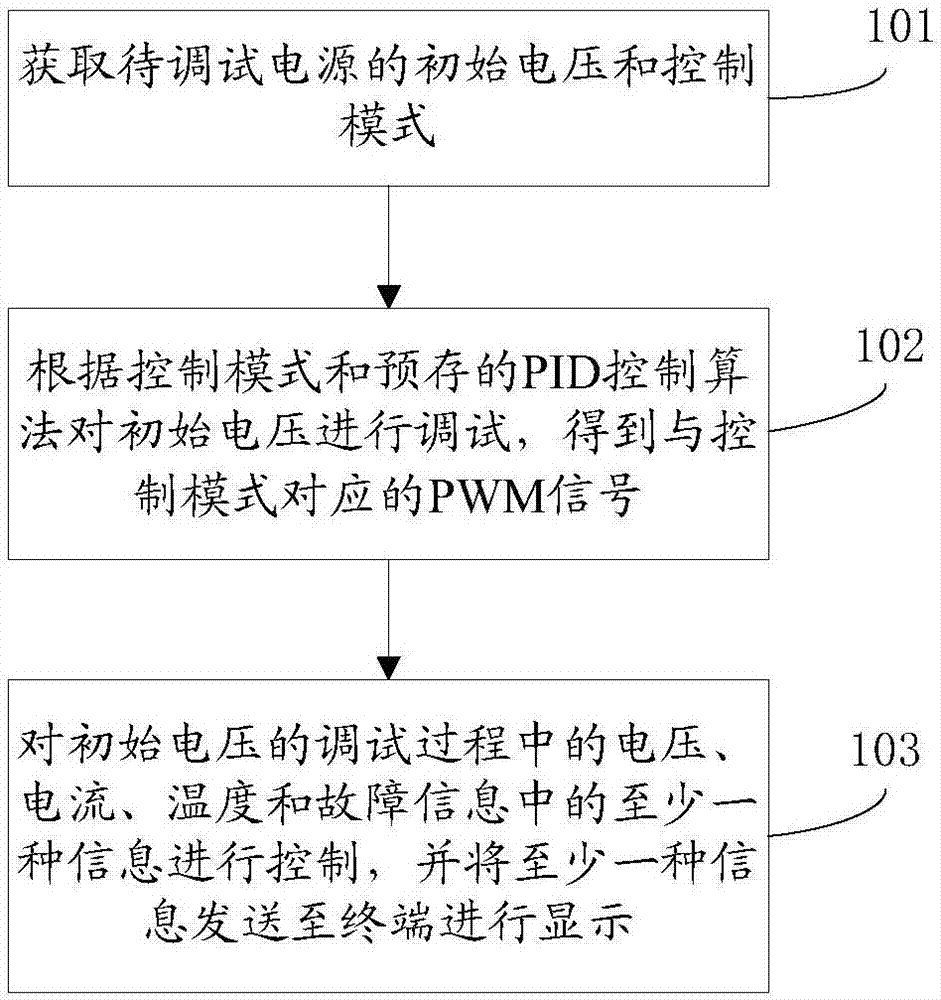

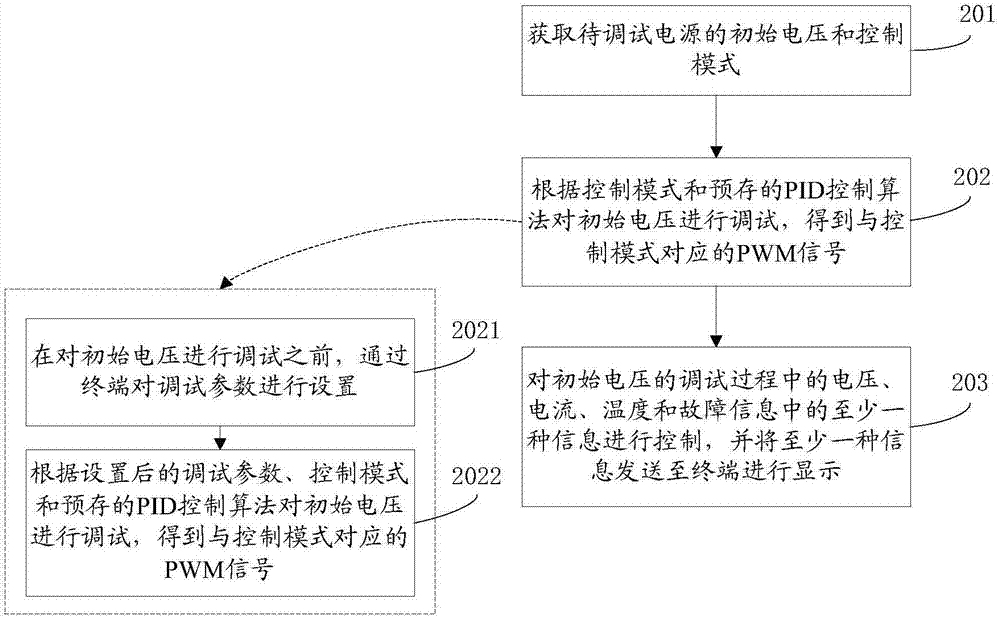

[0042] Such as figure 1 As shown, it is a schematic flowchart of a digital power supply control method provided by an embodiment of the present invention, and the control method mainly includes the following steps.

[0043] S101. Obtain the initial voltage and control mode of the power supply to be debugged. For example, the power supply to be debugged here may be a radar power supply.

[0044] S102, debug the initial voltage according to the control mode and the pre-stored PID control algorithm, and obtain a PWM signal corresponding to the control mode.

[0045] S103. Control at least one information among voltage, current, temperature and fault information during initial voltage debugging, and send at least one i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com