Lead-cooled fast reactor separable reactor core implementation scheme

A separation method and core technology, applied in the direction of reactor, climate sustainability, greenhouse gas reduction, etc., can solve the problems of slow insertion of shutdown rods and cannot be inserted, and achieve the effect of increasing passive safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

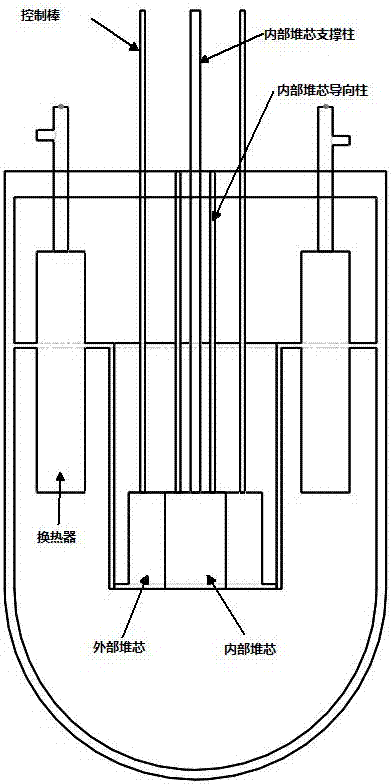

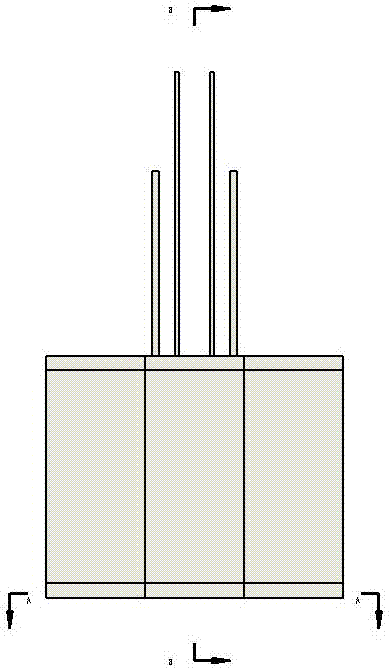

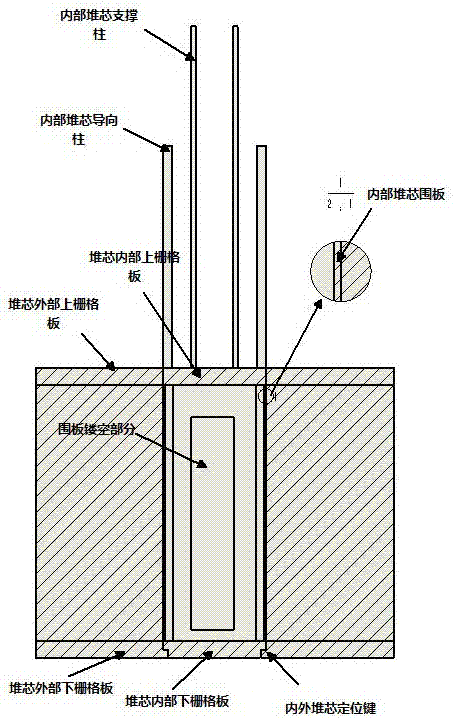

[0021] Such as image 3 The present invention shown is composed of inner core, outer core, upper grid plate inside the core, upper grid plate outside the core, lower grid plate inside the core, lower grid plate outside the core, and inner core coaming plate , the inner core support column, and the inner core guide column.

[0022] The normal core is divided into two parts, the inner core and the outer core, and the inner core accounts for 1 / 4 of the entire core.

[0023] Because the core is divided into two parts, the corresponding upper and lower grid plates should also be divided into two independent parts, divided into the upper grid plate inside the core, the upper grid plate outside the core, and the lower grid plate inside the core. The lower grid plate outside the core.

[0024] In order to realize the overall floating of the internal core, it is necessary to connect the internal upper and lower grid plates with the internal coaming plate of the core.

[0025] An app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com