A reverse osmosis membrane flushing system, water purifier and control method thereof

A technology of reverse osmosis membrane and flushing system, which is applied in the field of water purification, can solve the problem of high TDS value on the produced water side, and achieve the effects of delaying membrane fouling and prolonging membrane life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

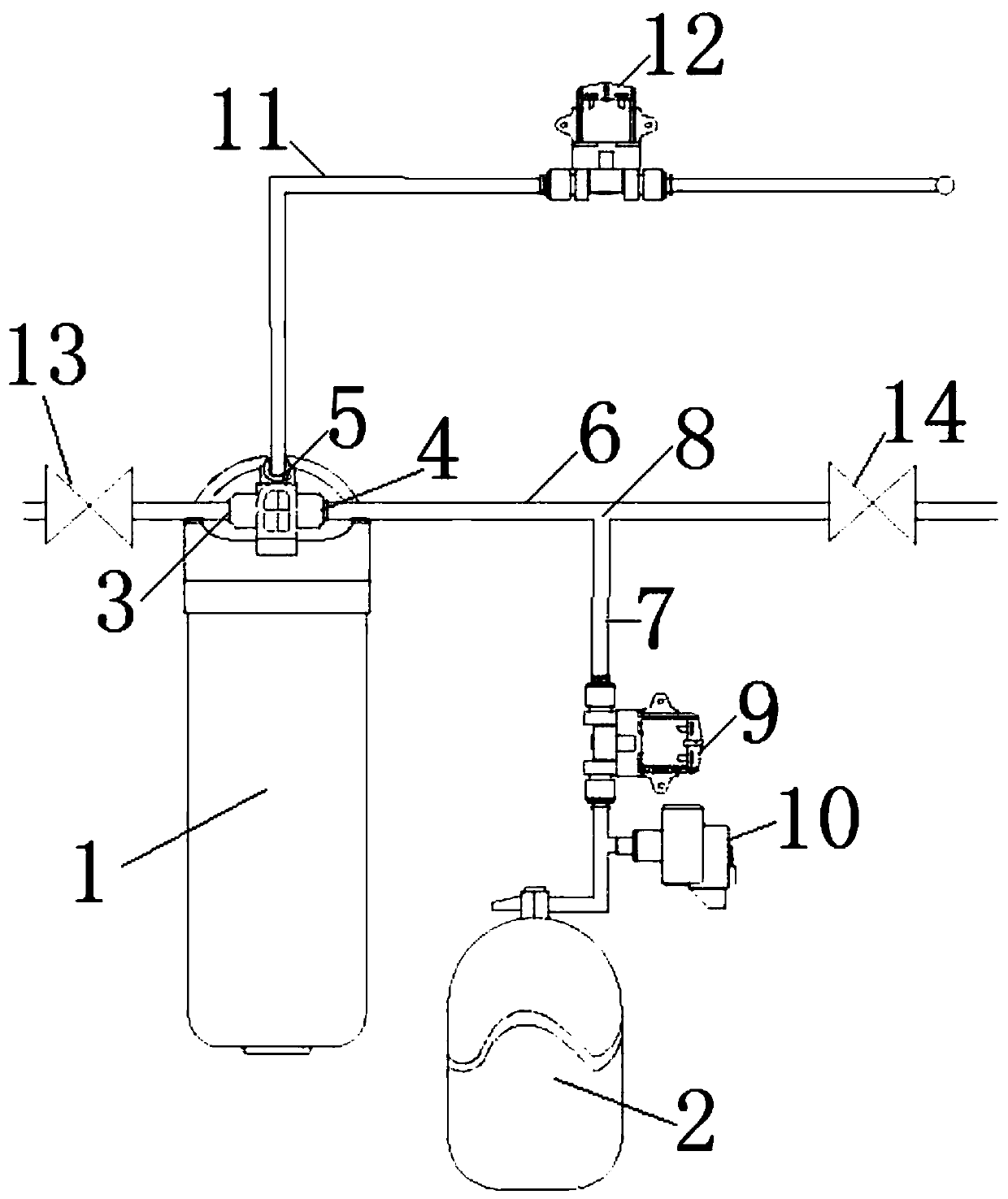

[0050] This embodiment provides a reverse osmosis membrane flushing system, such asfigure 1 shown, including:

[0051] A reverse osmosis membrane filter element 1, which includes: a water inlet 3 connected to a water inlet pipe; a clean water outlet 4 for clean water to flow out; and a concentrated water outlet 5 for concentrated water to flow out;

[0052] The flushing device 2 communicates with the clean water port 4, and the flushing water in it can be pressurized and enters the reverse osmosis membrane filter element 1 through the clean water port 4, so that the flushing water permeates to the concentrated water side to The concentrated water on the concentrated water side is replaced and the replaced concentrated water is discharged from the concentrated water port 5 .

[0053] In this embodiment, the flushing device 2 is a pressure tank.

[0054] In the above-mentioned reverse osmosis membrane flushing system, a water inlet 3, a clean water port 4 and a concentrated wat...

Embodiment 2

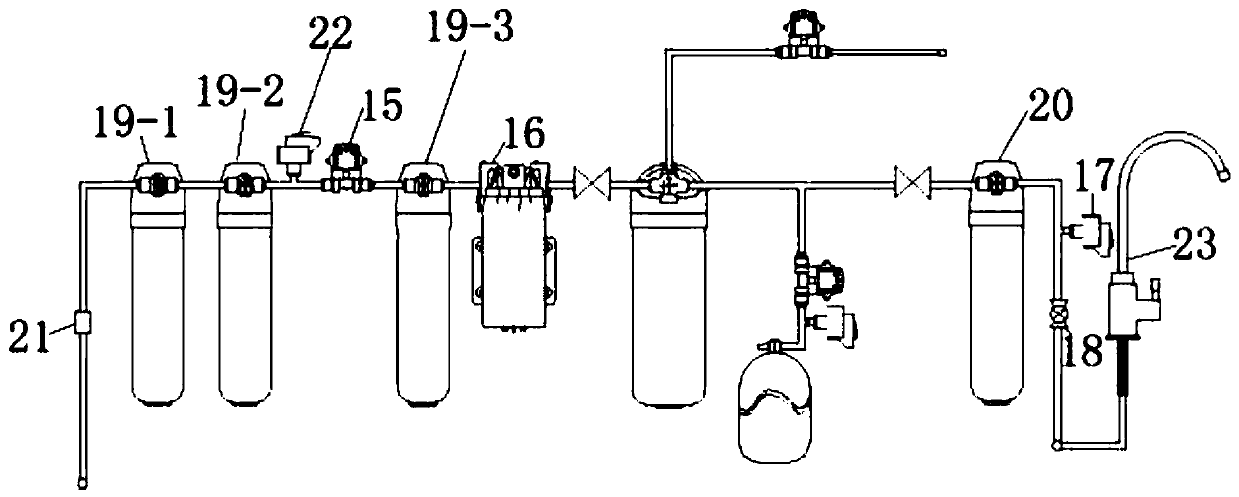

[0065] This embodiment provides a water purifier, such as figure 2 As shown, the reverse osmosis membrane flushing system in Example 1 is included. By adopting the reverse osmosis membrane flushing system in Example 1, the problem of high TDS value on the produced water side after the water purifier stops producing water for a period of time can be solved.

[0066] In order to improve the water purification effect, it also includes several pre-stage purification modules 19, which are arranged on the water inlet pipe, to carry out pre-stage purification to the water in the water inlet pipe; several post-stage purification modules 20, which are arranged on the water purification On the pipe 6, to carry out post-stage purification to the water in the water purification pipe 6.

[0067] Further, a decompression valve 21 is included, which is arranged on it away from the pre-purification module 19 and close to the water inlet end of the water inlet pipe;

[0068] The first high-...

Embodiment 3

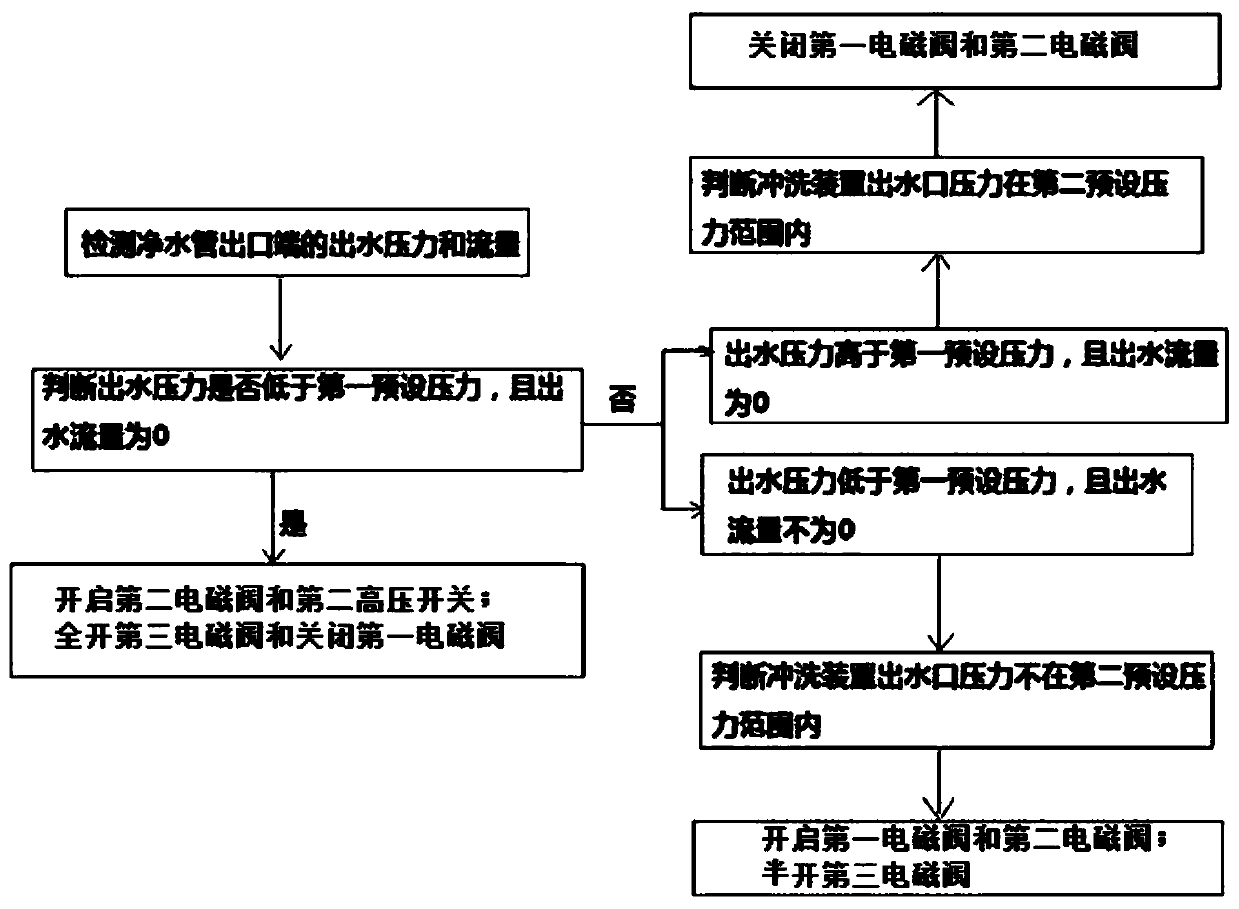

[0077] This embodiment provides a control method for the reverse osmosis membrane flushing system in Embodiment 1, such as image 3 shown, including the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com