Fermentation technology for improving production level of recombinant collagen

A technology of recombinant collagen and production level, applied in fermentation, animal/human protein, microorganism-based methods, etc., can solve the problems of aggravated protein degradation, bacterial decline, affecting protein quality, etc., to improve the supplementation of trace elements, inhibit the Collagenase production, the effect of reducing the concentration of salt ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

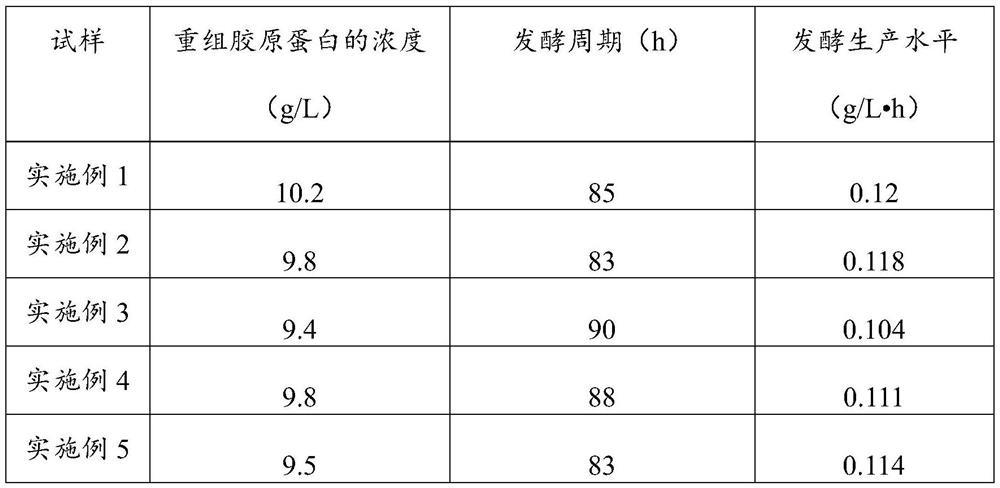

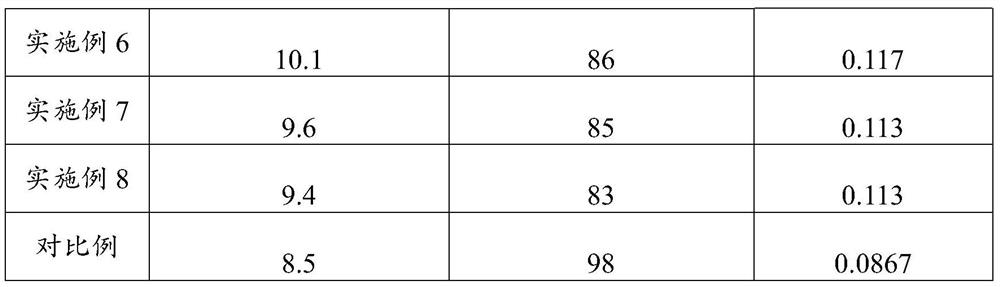

Examples

Embodiment 1

[0038] This embodiment provides a fermentation process for improving the production level of recombinant collagen, comprising the following steps:

[0039]S1: Inoculate the Pichia pastoris engineered bacteria into a 100L seed tank containing 70L fermentation medium according to the inoculum amount of 10%. , add 50% glycerol and feed medium after dissolved oxygen rises sharply, the flow acceleration rate of 50% glycerol is 10mL / h / L, and the flow acceleration rate of feed medium is 5mL / h / L; When the weight increased to 160g / L, transplant it into a 1500L fermenter containing 700L fermentation medium to start fermentation culture, the temperature was 28°C, the pH was adjusted to 4.8 with ammonia water, the tank pressure was 0.06MPa, and the dissolved oxygen was not less than 30%;

[0040] S2: Cultivate the Pichia pastoris engineering bacteria in the fermenter until the dissolved oxygen rises sharply, then use 50% glycerol and feed medium for mixed carbon source feeding, and the fl...

Embodiment 2

[0045] This embodiment provides a fermentation process for improving the production level of recombinant collagen, comprising the following steps:

[0046] S1: Inoculate the Pichia pastoris engineered bacteria into a 100L seed tank containing 50L fermentation medium according to the inoculation amount of 6%, and cultivate them at a temperature of 30°C, adjusting the pH to 5.5 with ammonia water, tank pressure 0.06MPa, and dissolved oxygen not less than 30% , add 50% glycerol and feed medium after dissolved oxygen rises sharply, the flow acceleration rate of 50% glycerol is 16mL / h / L, and the flow acceleration rate of feed medium is 6mL / h / L; When the weight increased to 180g / L, transplant it into a 1500L fermenter containing 600L fermentation medium to start fermentation culture, the temperature was 30°C, the pH was adjusted to 5.5 with ammonia water, the tank pressure was 0.06MPa, and the dissolved oxygen was not less than 30%;

[0047] S2: Cultivate the Pichia pastoris enginee...

Embodiment 3

[0052] This embodiment provides a fermentation process for improving the production level of recombinant collagen, comprising the following steps:

[0053] S1: Inoculate the Pichia engineered bacteria into a 100L seed tank containing 60L fermentation medium according to the inoculum amount of 8%, and cultivate them at a temperature of 32°C, adjusting the pH to 5.0 with ammonia water, tank pressure 0.05MPa, and dissolved oxygen not less than 30% , add 50% glycerol and feed medium after dissolved oxygen rises sharply, the flow acceleration rate of 50% glycerol is 13mL / h / L, and the flow acceleration rate of feed medium is 6mL / h / L; When the weight increased to 180g / L, transplant it into a 1500L fermenter containing 650L fermentation medium to start fermentation culture, the temperature was 32°C, the pH was adjusted to 5.0 with ammonia water, the tank pressure was 0.05MPa, and the dissolved oxygen was not less than 30%;

[0054] S2: Cultivate the Pichia pastoris engineering bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com