Sorting and grouping method for lithium ion power batteries

A power battery and lithium-ion technology, which is applied in the field of lithium-ion power battery sorting and matching groups, can solve problems such as large demand, low battery sorting efficiency and pass rate, and battery group consistency that cannot meet customer expectations. To achieve the effect of improving charge and discharge performance and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

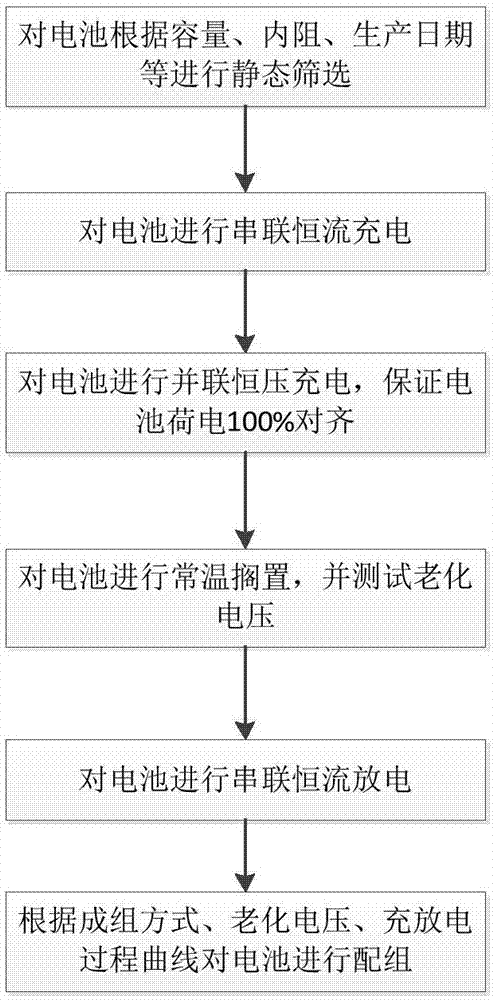

[0035] The lithium-ion power battery sorting and matching method of the present embodiment includes the following steps, such as figure 1 Shown:

[0036] 1) According to static parameters such as capacity, voltage, internal resistance, and production date, select batteries that are more than 10% of the required number of batteries, and the capacity difference can be selected according to the number of batteries connected in parallel. 500 qualified batteries within the same month (internal resistance and voltage within the qualified range); the lithium-ion power battery used in this embodiment is a lithium iron phosphate battery with a single capacity of 72Ah;

[0037] 2) Use special probe equipment 1 to connect 500 batteries in series, charge at a charging rate of 0.5C until the voltage of the single battery is 3.6V, and then charge at a constant voltage of 3.6V until the current is 0.15C and stop charging;

[0038] Record the time and voltage data of the charging process;

...

Embodiment 2

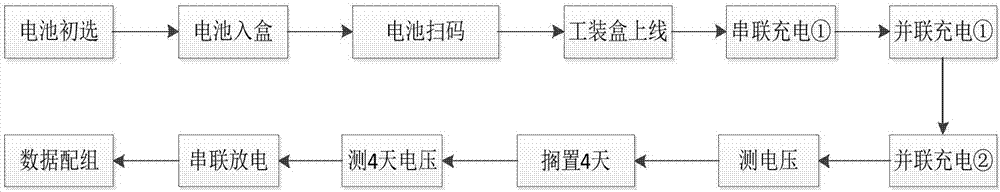

[0044] The lithium-ion power battery sorting and matching method of the present embodiment includes the following steps, such as figure 2 Shown:

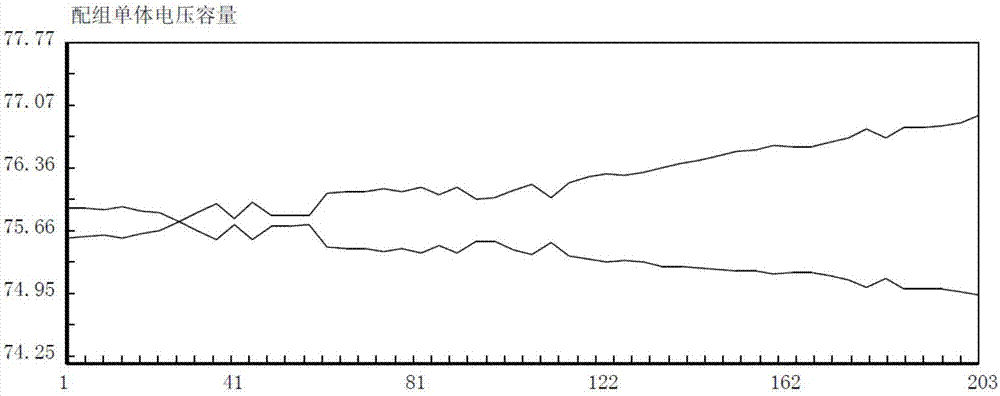

[0045] This matching method is applicable to any series-parallel battery matching group, and the effect of multi-parallel multi-string battery matching is better. The battery grouping method required in this embodiment is 2 and 203 strings; the lithium ion battery used The power battery is a lithium iron phosphate battery with a single capacity of 74Ah;

[0046] 1) According to static parameters such as capacity, voltage, internal resistance and production date, select batteries that are more than 10% of the required number of batteries. The capacity difference can be selected according to the number of batteries connected in parallel. Select a capacity difference ≤ 2Ah, and the production date is within the same month 480 batteries;

[0047] 2) Use special probe equipment 1 to connect 480 batteries in series, charge at a chargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com