Blast electric hammer for self powerful hole cleaning after hole drilling for embedding steel bars

An electric hammer and hole cleaning technology, which is used in light impact tools, metal processing equipment, maintenance and safety accessories, etc., can solve the problem of inflexible use, and achieve the effect of convenient on-site handling, high efficiency and convenient carrying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

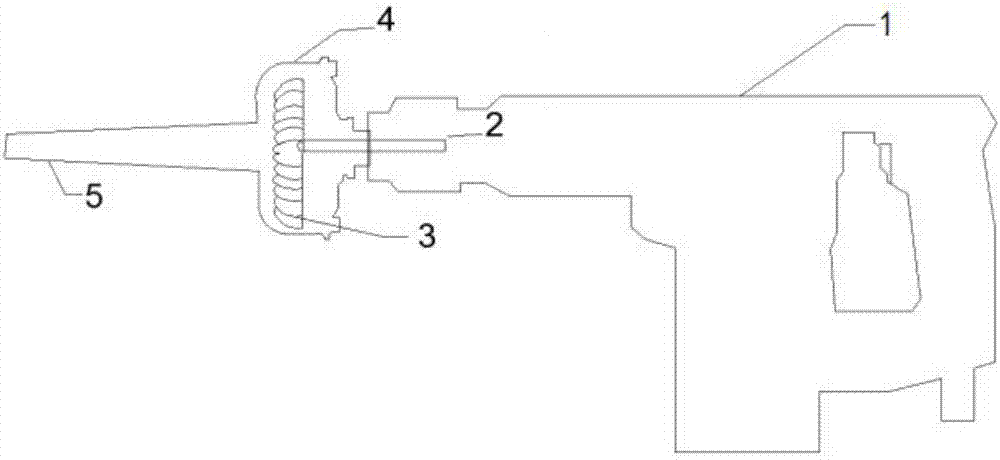

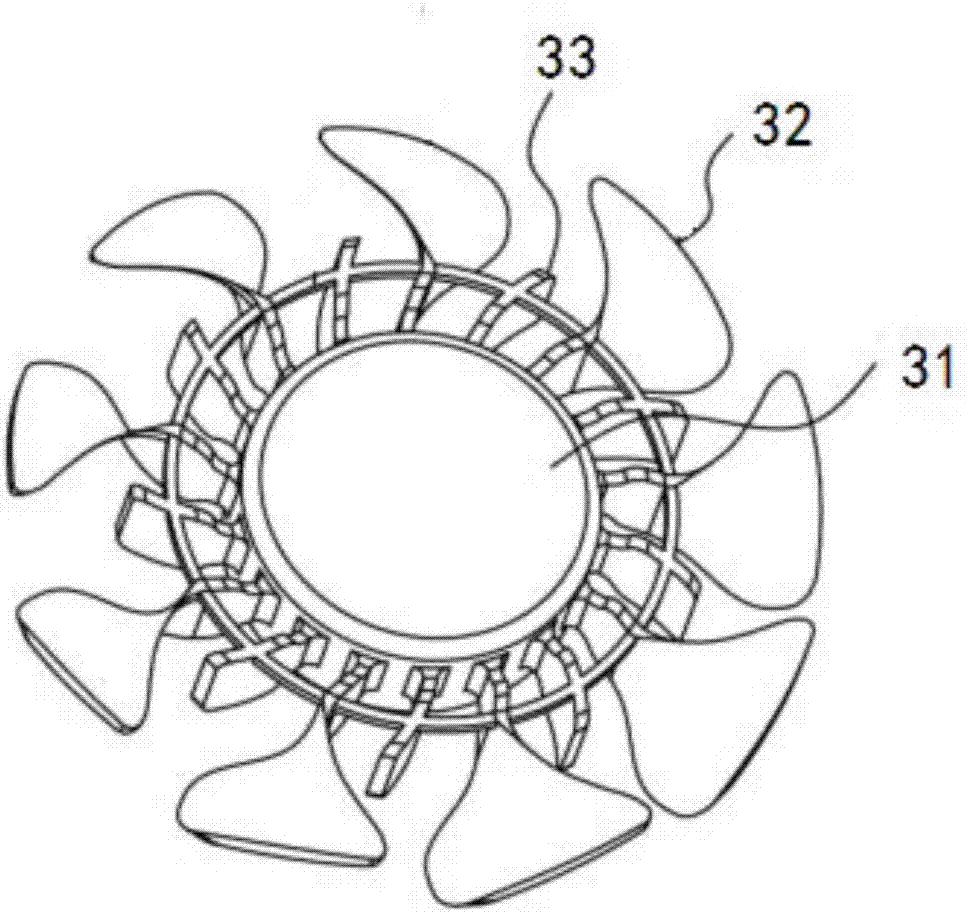

[0021] Such as figure 1 with figure 2 As shown, this example is a kind of air blowing electric hammer for self-clearing holes after planting reinforcement drilling, including electric hammer body 1, air blowing blade set 3 and blade guard 4, and air blowing blade set 3 includes hub 31 and the second One blade 32, the hub 31 is arranged at the center of the blower blade group 3, the first blade 32 is fixedly arranged on the hub 31, the number of the first blades 32 is odd and the number of the first blades 32 is at least three, in practical application, it can Select five, seven or more first blades 32 according to needs, and the first blades 32 are evenly distributed along the outer circumference of the hub 31. The face shield is provided with a blade guard 4, the diameter of the blade guard 4 is between 100mm-150m, one end of the blade guard 4 is provided with an air outlet pipe 5, and the total length of the blast blade group 3 and the air outlet pipe 5 is 200mm-250mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com