Production and manufacturing method of aluminum honeycomb energy absorbing module

A manufacturing method, aluminum honeycomb technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of cumbersome procedures, low processing efficiency, and difficult control of processing accuracy, so as to improve processing efficiency and reduce Labor intensity, the effect of reducing the requirements of press molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

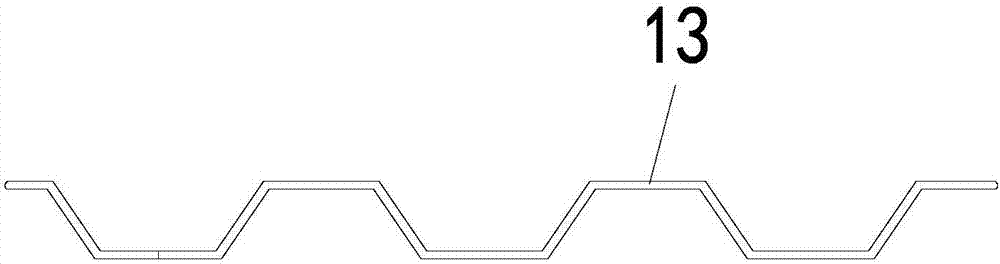

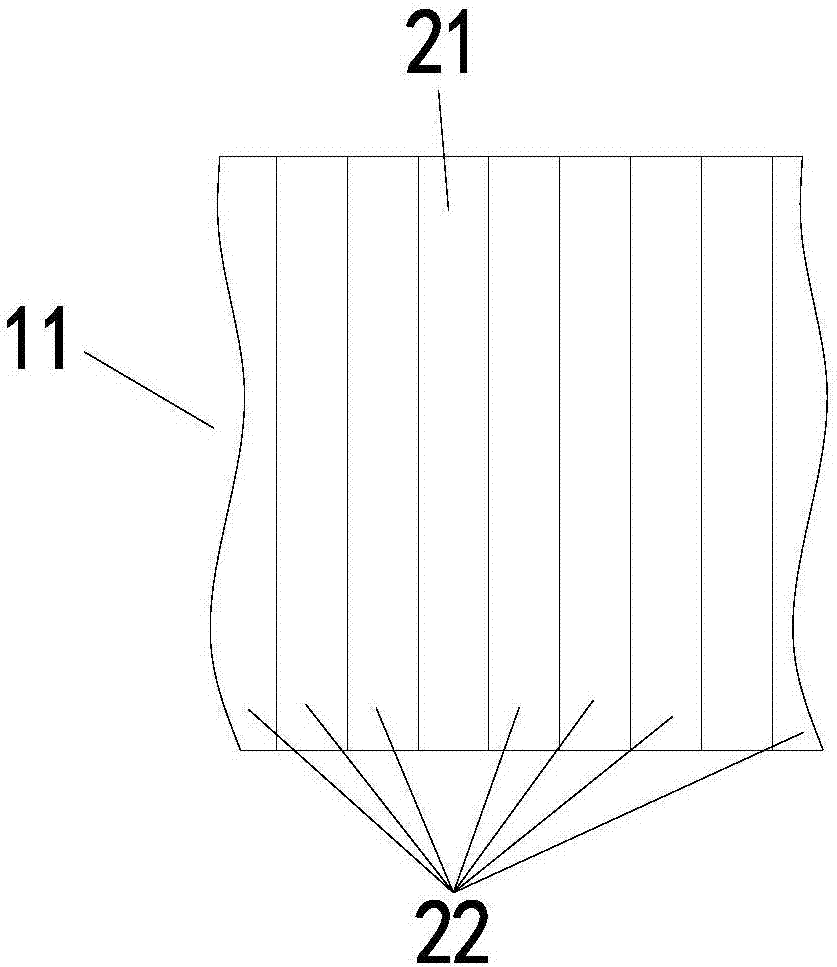

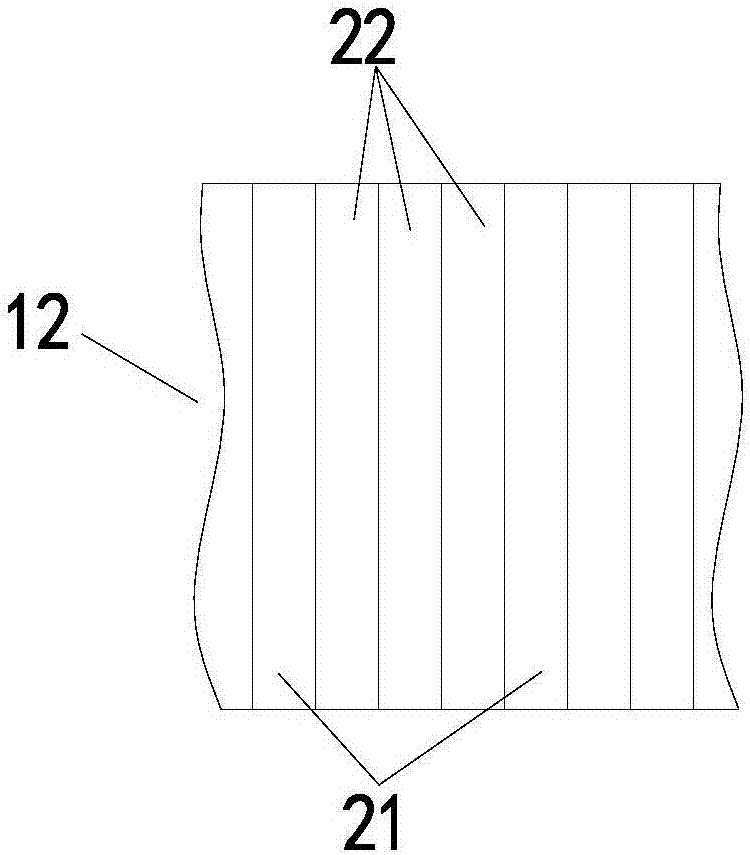

[0053] Set the length and width of the end face of the honeycomb module body 3 to be 50cm, that is: the length and width of the aluminum plate 4 are 50cm, the height of the honeycomb core structure 7 is 50cm, the thickness of the selected aluminum foil is 0.08mm, and the width of the adhesive tape 21 1.4mm.

Embodiment 2

[0055] Set the length and width of the end face of the honeycomb module body 3 to be 50cm, that is: the length and width of the aluminum plate 4 are 50cm, the height of the honeycomb core structure 7 is 50cm, the thickness of the selected aluminum foil is 0.08mm, and the width of the adhesive tape 21 1.18mm.

Embodiment 3

[0057] Set the length and width of the end face of the honeycomb module body 3 to be 50cm, that is: the length and width of the aluminum plate 4 are 50cm, the height of the honeycomb core structure 7 is 50cm, the thickness of the selected aluminum foil is 0.08mm, and the width of the adhesive tape 21 1.15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com