Nozzle wiping mechanism and ink-jet printer

A nozzle and wiping roller technology, which is applied in printing and other directions, can solve the problems of silicone scraper contamination, poor wiping effect, and affecting the efficiency of inkjet printing, etc., to achieve the effect of convenient operation and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

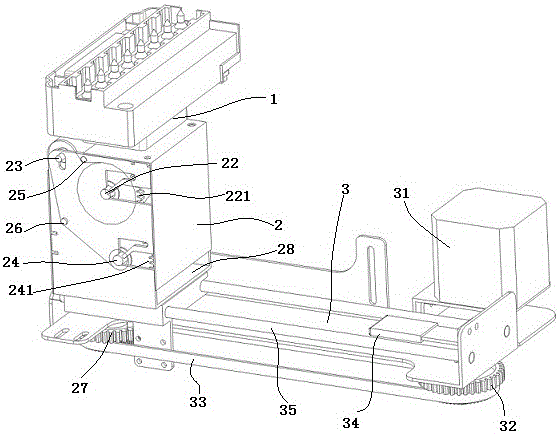

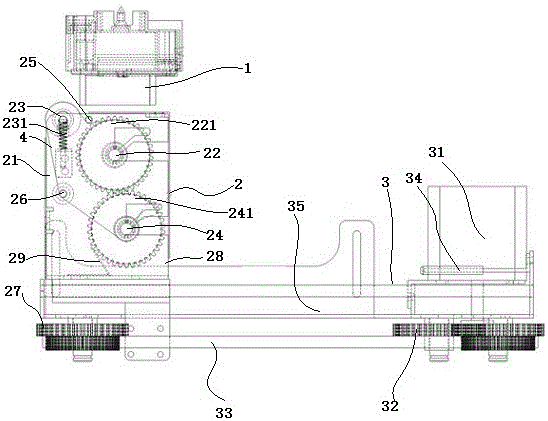

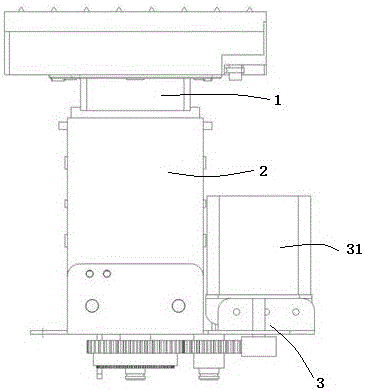

[0031] figure 1 with figure 2 A schematic structural view and a cross-sectional view of the internal structure of the nozzle wiping mechanism of this embodiment are given respectively, image 3 A schematic diagram of the structure of the nozzle wiping mechanism in this embodiment located at the receiving station is given. combined reference Figure 1~Figure 3 , a nozzle wiping mechanism, including a nozzle 1, a wiping system 2 and a transmission system 3. Wherein, the wiping system 2 is located above the transmission system 3 and below the nozzle 1, and the transmission system 3 drives the wiping system 2 to move left and right. Such as figure 2 with image 3 As shown, when the wiping system 3 is located on the left side of the transmission system, it is at the wiping station to perform the wiping and cleaning work of the nozzle 1; when the wiping system 3 is located on the right side of the transmission system, it is at the receiving station to perform wiping material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com