Automatic packing belt cutting and box feeding system

A technology of automatic box packing and tape cutting, which is applied in the directions of bundling objects, packaging/bundling items, packaging, etc., and can solve the problems of high labor intensity and high temperature in sorting cartons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

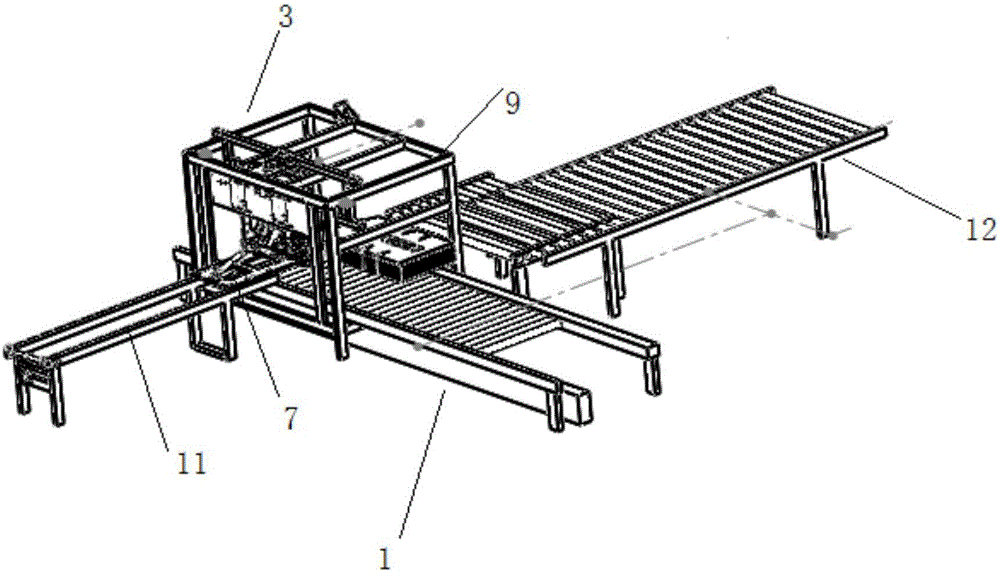

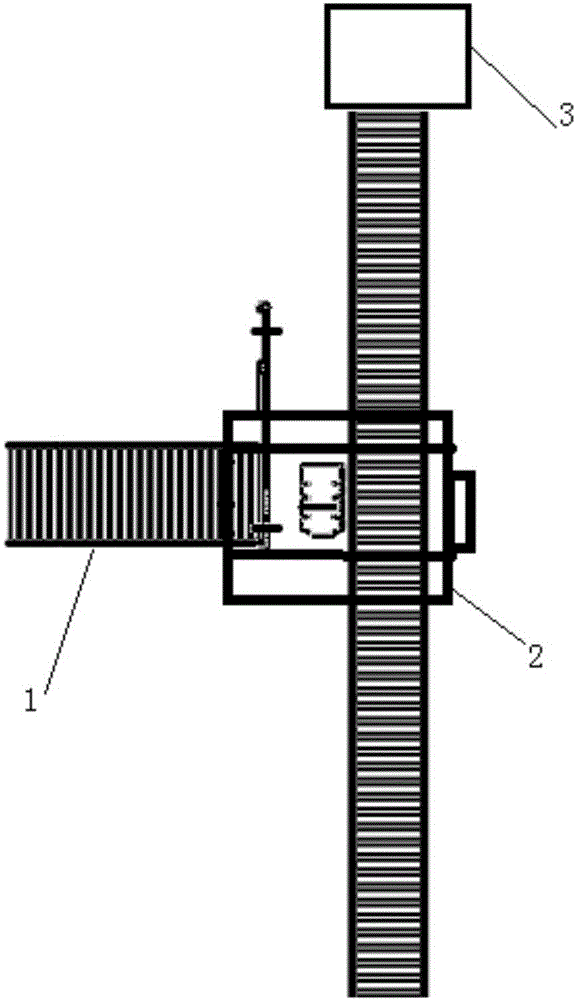

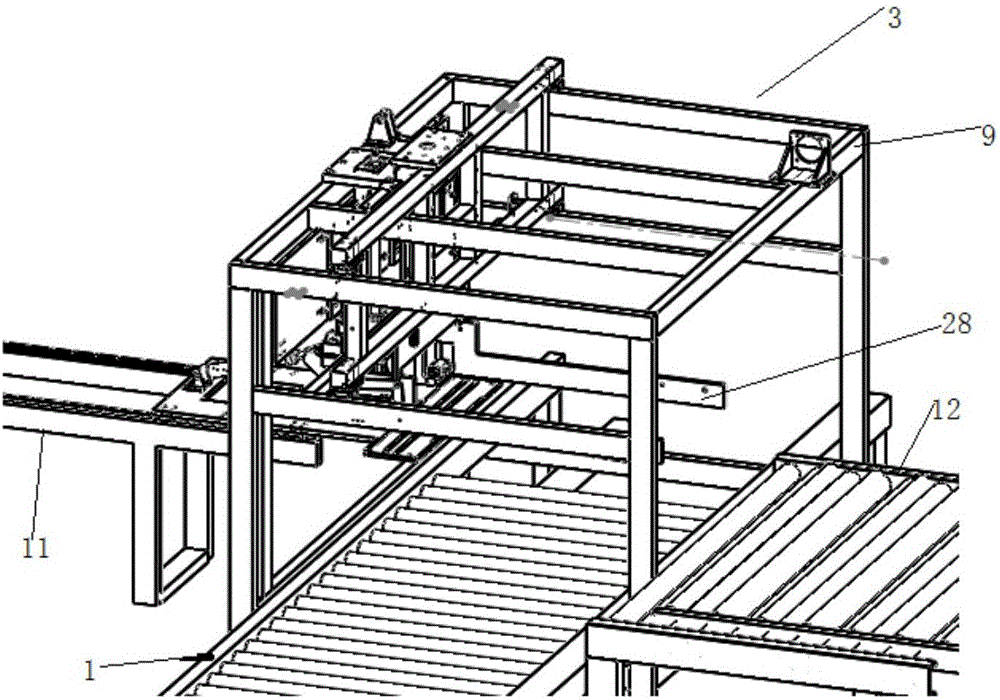

[0025] An automatic cutting belt box supply system, comprising a conveyor belt, an automatic box packing machine 2, and an automatic belt cutting machine 3, wherein the conveyor belt, the automatic box packing machine 2, and the automatic belt cutting machine 3 are connected in sequence, and the conveyor belt includes mutually perpendicular first A conveyor belt 1 and a second conveyor belt 12, the automatic belt cutting machine 2 is provided with a sorting mechanism 4, and the cartons bound with packing belts are transported from the warehouse to the automatic belt cutting machine 3 through the first conveyor belt 1, and the box sorting mechanism 4 descends so that The cartons bundled with packing tape stop at the designated position to prepare for cutting off the packing tape; automatic tape cutting machine 3 includes blade 5, cylinder 6, belt drawer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com