Chain conveyer transmission structure with mechanical protection function

A technology of chain conveyor and transmission structure, which is applied in the direction of conveyor, transportation, packaging, packaging, etc., which can solve problems such as affecting normal production, increasing maintenance costs, and difficult maintenance of devices, so as to avoid damage to machinery and burn out motors , increase the mechanical protection function, reduce the effect of maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

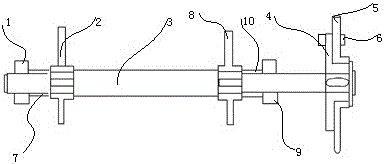

[0011] Such as figure 1 As shown, a chain conveyor transmission structure with mechanical protection function, including the first bearing seat 1, the first conveyor driving sprocket 2, the driving shaft 3, the fixed plate 4, the driving passive sprocket 5, and the protective sheath 6 , the second conveyor drive sprocket 8 and the second bearing seat 9, the drive shaft 3 runs through the first bearing seat 1, the first conveyor drive sprocket 2, the second conveyor drive sprocket 8 and the second bearing In the seat 9, the first bearing seat 1 is compatible with the second bearing seat 9; the first conveyor driving sprocket 2 is compatible with the second conveyor driving sprocket 8; one end of the driving shaft 3 is clamped on the fixed In the disk 4, a driving passive sprocket 5 is arranged on one side of the fixed disk 4, and the fixed disk 4 and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com