Environment-friendly cutting oil and preparation method thereof

A cutting oil and environmental protection technology, applied in the field of environmental protection cutting oil and its preparation, can solve the problems of easy residue, difficult to remove, non-degradable components, etc., and achieve the effect of good lubricating performance and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides an environmentally friendly cutting oil, including the following components in parts by weight: isooctyl stearate: 35g; Guerbet alcohol: 40g; diisooctyl sebacate: 20g; pentaerythritol oleate: 5g , follow the steps below to prepare cutting fluid:

[0024] S 1 : Add Guerbet alcohol and isooctyl stearate into the preparation tank according to the corresponding weight, stir with a mixer for 15min; stirring speed 100r / min;

[0025] S 2 : Add the corresponding weight of di-isooctyl sebacate into the preparation tank, stir with a mixer for 30min; the stirring speed is 80r / min;

[0026] S 3 : Add the corresponding weight of pentaerythritol oleate into the preparation tank, and stir with a mixer for 30 minutes; the stirring speed is 80r / min.

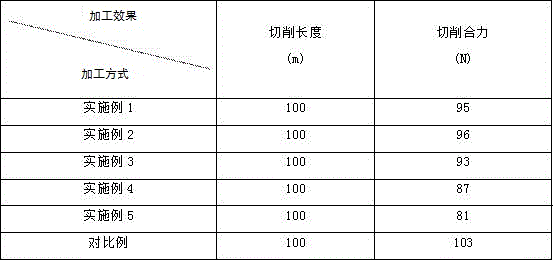

[0027] In this embodiment, all are compared with the cutting effect under the same cutting parameters. During the cutting process, the Kister9129A three-way force measuring system was used to measure the cutti...

Embodiment 2

[0029] The present embodiment provides an environmentally friendly cutting oil, including the following weight components: isooctyl stearate: 25g; Guerbet alcohol: 30g; diisooctyl sebacate: 40g; pentaerythritol oleate: 5g, Follow the steps below to prepare cutting fluid:

[0030] S 1 : Add Guerbet alcohol and isooctyl stearate into the preparation tank according to the corresponding weight, stir with a mixer for 15min; stirring speed 80r / min;

[0031] S 2 : Add the corresponding weight of di-isooctyl sebacate into the preparation tank, stir with a mixer for 30min; the stirring speed is 100r / min;

[0032] S 3 : Add the corresponding weight of pentaerythritol oleate into the preparation tank, and stir with a mixer for 30 minutes; the stirring speed is 90r / min.

[0033] In this embodiment, all are compared with the cutting effect under the same cutting parameters. During the cutting process, the Kister9129A three-way force measuring system was used to measure the cutting for...

Embodiment 3

[0035] The present embodiment provides an environmentally friendly cutting oil, comprising the following weight components: isooctyl stearate: 28g; Guerbet alcohol: 35g; diisooctyl sebacate: 35g; pentaerythritol oleate: 2g, Follow the steps below to prepare cutting fluid:

[0036] S 1 : Add Guerbet alcohol and isooctyl stearate into the preparation tank according to the corresponding weight, stir with a mixer for 15min; stirring speed 80r / min;

[0037] S 2 : Add the corresponding weight of di-isooctyl sebacate into the preparation tank, stir with a mixer for 30min; the stirring speed is 100r / min;

[0038] S 3 : Add the corresponding weight of pentaerythritol oleate into the preparation tank, and stir with a mixer for 30 minutes; the stirring speed is 90r / min.

[0039] In this embodiment, all are compared with the cutting effect under the same cutting parameters. During the cutting process, the Kister9129A three-way force measuring system was used to measure the cutting fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com