Stationary controls for heating trays and equipment therefor

A control device and tray technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of unstable tray, tray rollover, tray rollover under force, etc., and achieve convenient pick-and-place control , The effect of improving temperature uniformity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

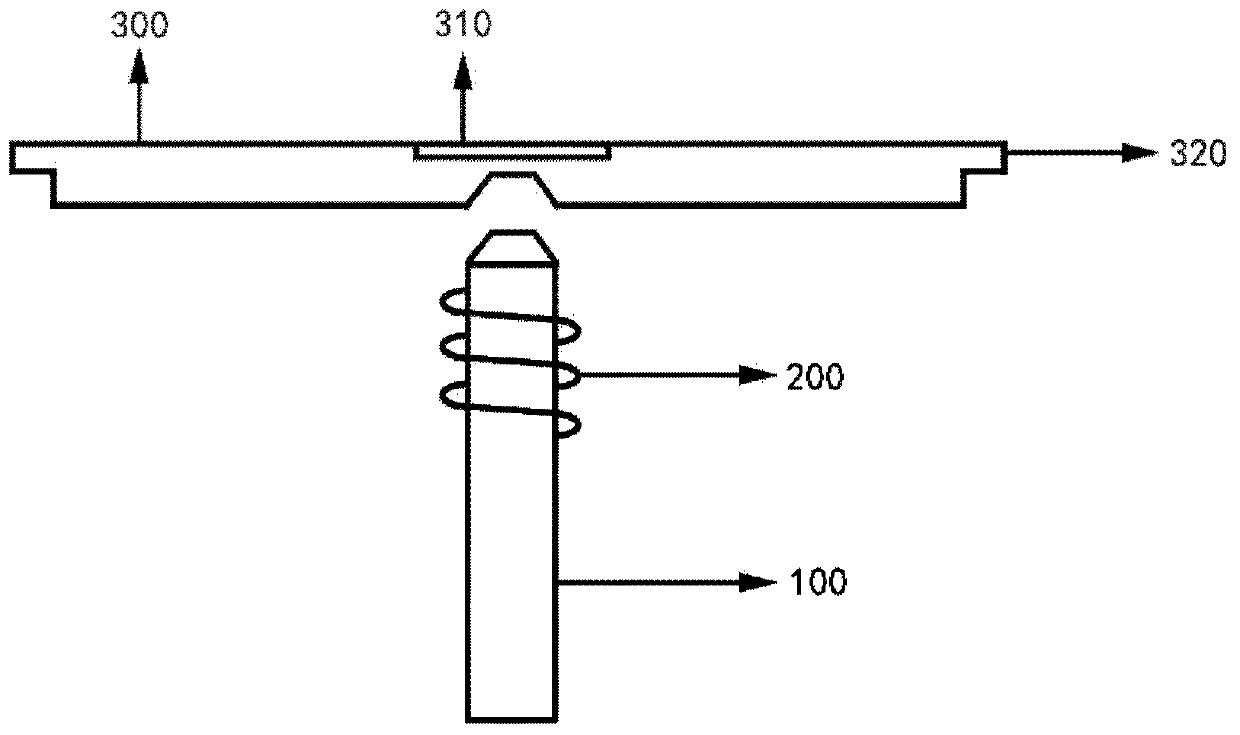

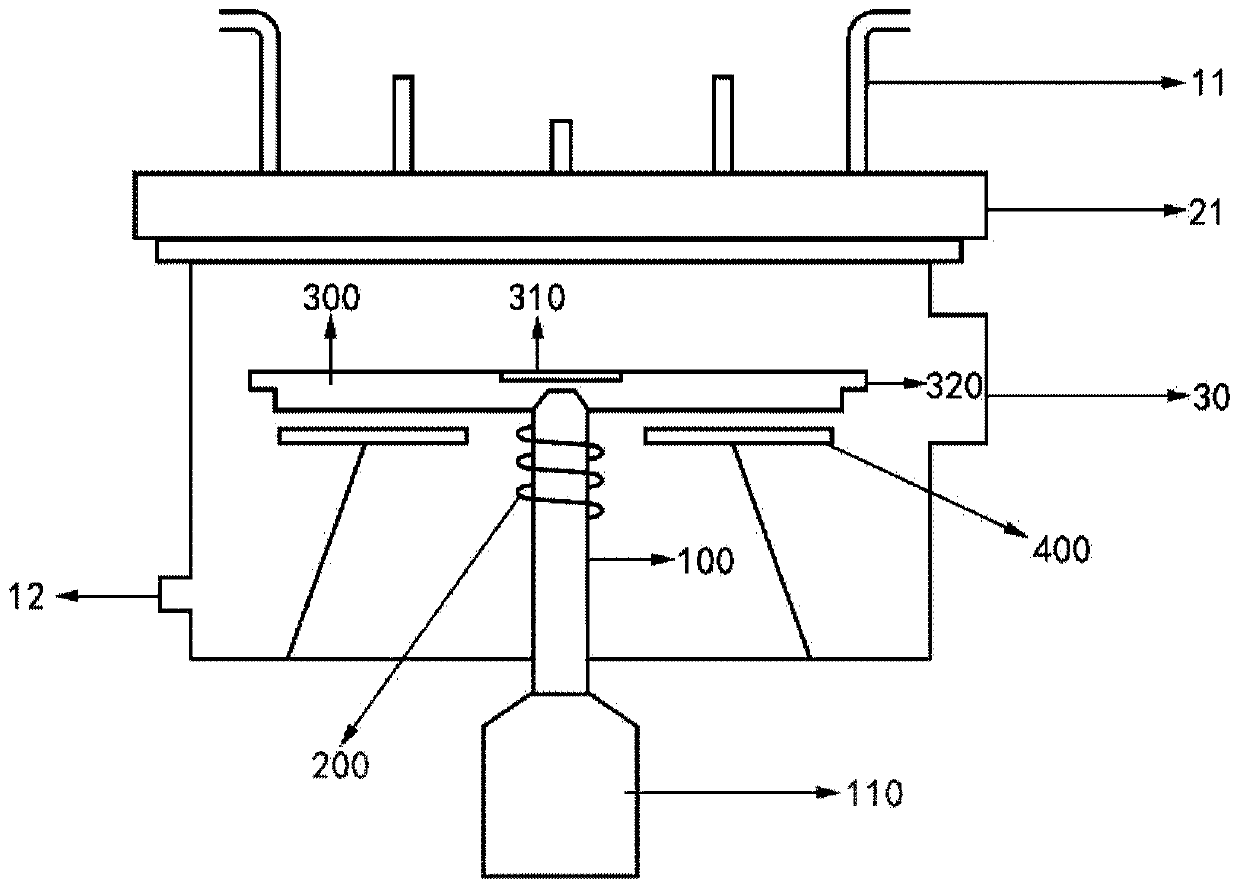

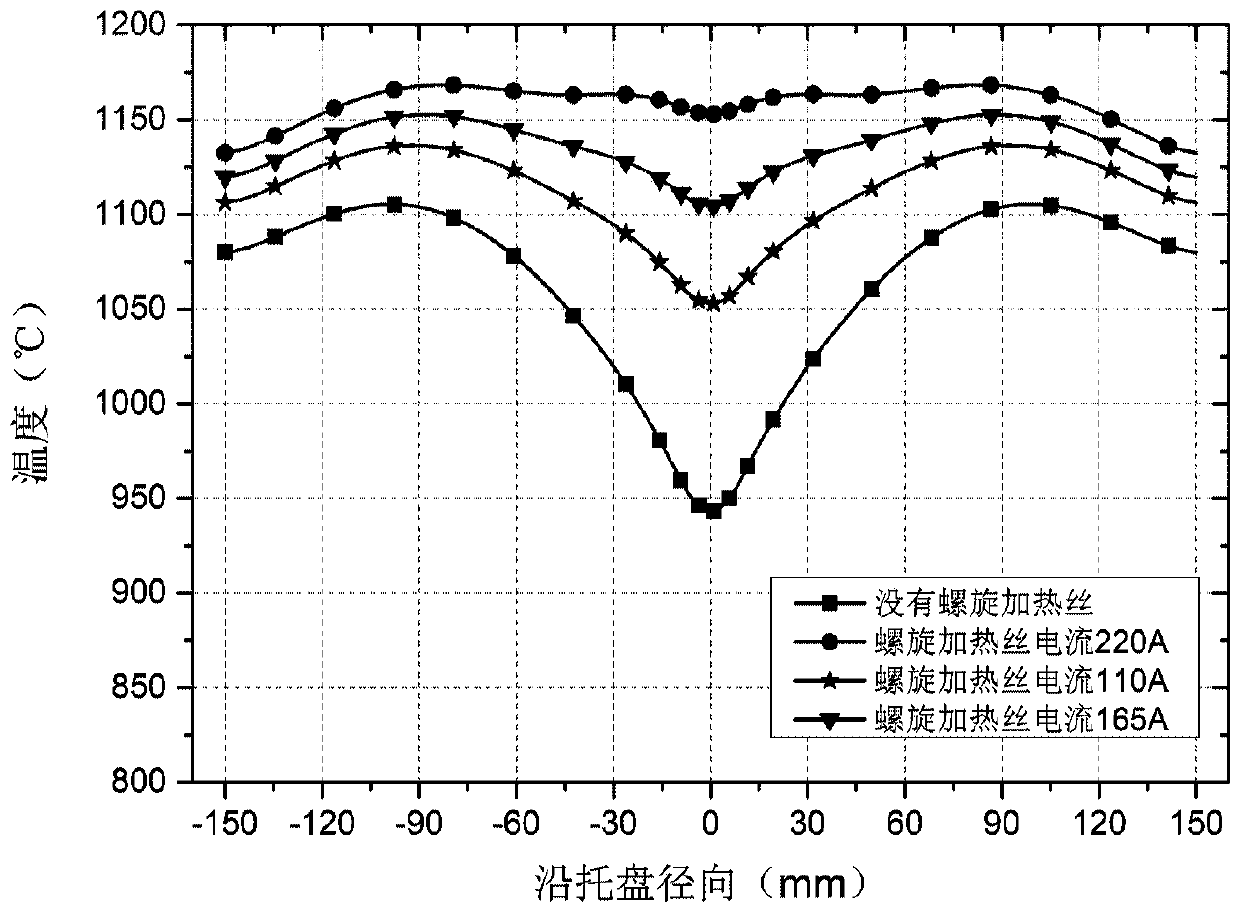

[0032] The disclosure provides a fixed control device for a heating tray and its equipment. By setting a spiral heating wire on the periphery of the rotating shaft that is spaced from the rotating shaft and forming an electromagnet structure, and controlling the on-off of the spiral heating wire, it can realize The fixed state control of the tray and the rotating shaft has a simple structure and is convenient for taking and placing control; at the same time, the heating control of the central area of the tray can be realized by adjusting the current of the spiral heating wire, so as to meet different sizes of trays and different growth temperatures. It can effectively improve the temperature uniformity of the tray.

[0033] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com