A lithium-ion battery module thermal balance management system

A battery management system, lithium-ion battery technology, applied in the direction of batteries, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of incomplete release of capacity, thermal runaway, safety accidents, etc., to reduce the risk of high temperature thermal runaway and the probability of low temperature damage to the battery, prolonging the service life and increasing the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

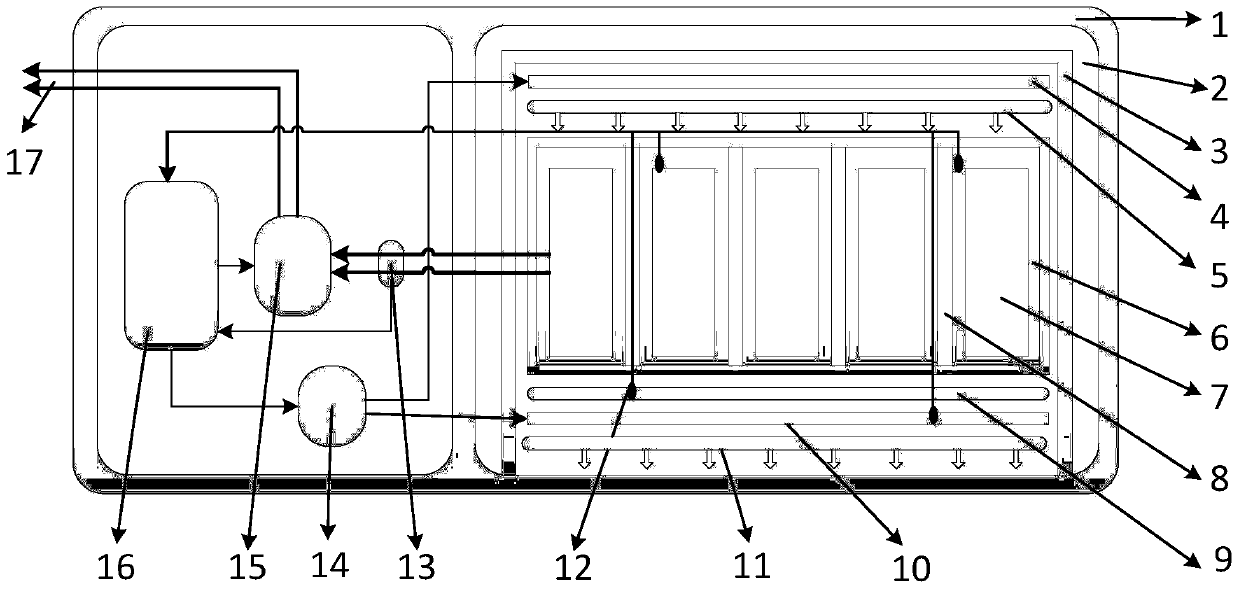

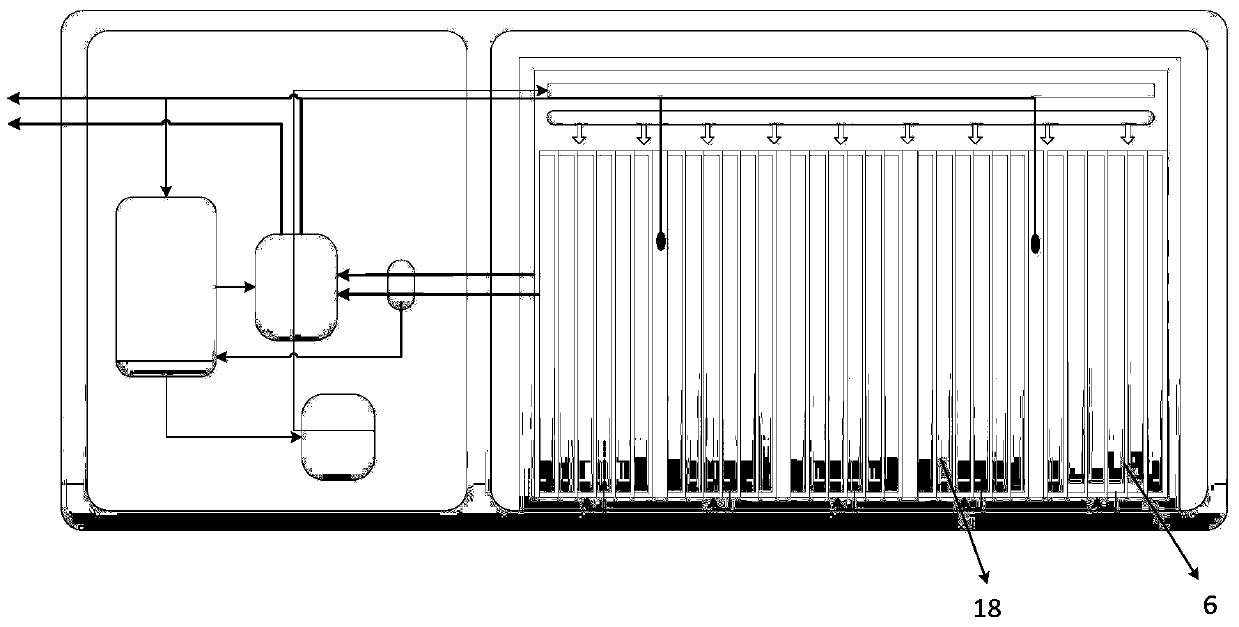

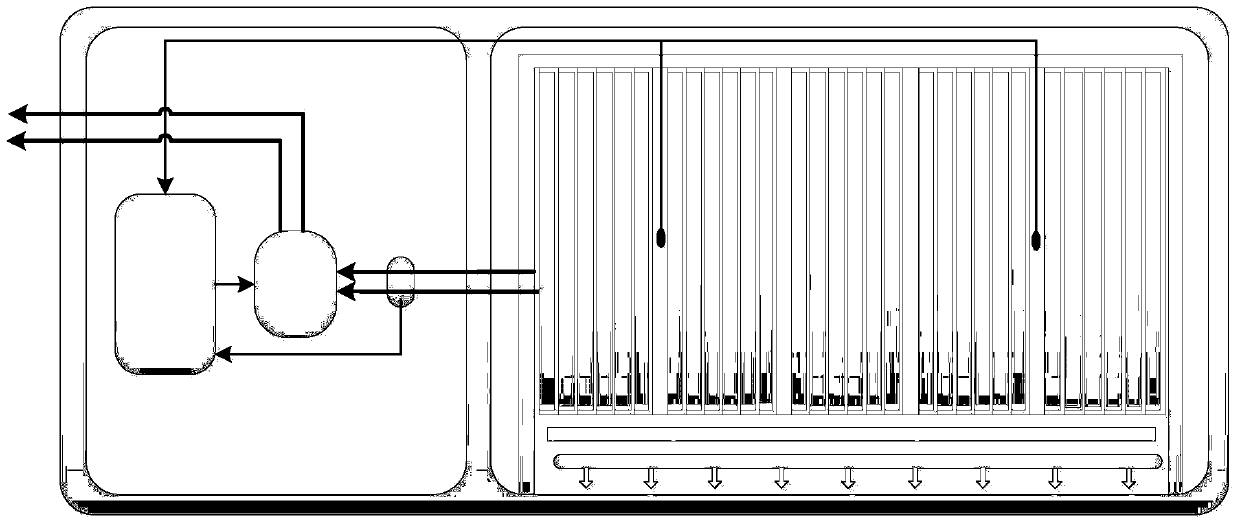

[0019] Such as figure 1 As shown, the lithium-ion battery module includes a battery module casing 1, a gas-resistant bag 2, a plastic fastener 3, a heating film 4, a deformable heat conduction pad 5, a heat conduction structural member 6, and a lithium-ion soft pack single cell 7, Electrostatic isolation pad 8, deformation heat conduction pad 9, equalizing resistance diaphragm 10, heat sink 11, temperature sensor 12, current sensor 13, equalization and temperature control circuit board 14, electronic switch 15, battery management system circuit board 16, power output terminal 17.

[0020] Specifically, the lithium-ion soft-packed single battery cell 7 of this embodiment can be a polymer lithium-ion battery cell, a liquid lithium-ion battery cell packaged in aluminum-plastic film, a solid-state lithium-ion battery cell packaged in aluminum-plastic film, or an aluminum-plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com