Positioning system and positioning method for optical module for automobile lamp

A technology of optical components and positioning systems, applied in the direction of headlights, light source fixing, vehicle parts, etc., can solve the problem of not meeting the installation accuracy of optical modules in the headlights, physical light distribution not meeting regulatory requirements, LED circuit boards and concentrating light. To solve the problem of large assembly tolerance of the device, it can achieve the effect of less assembly dimension chain, reducing assembly error and improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

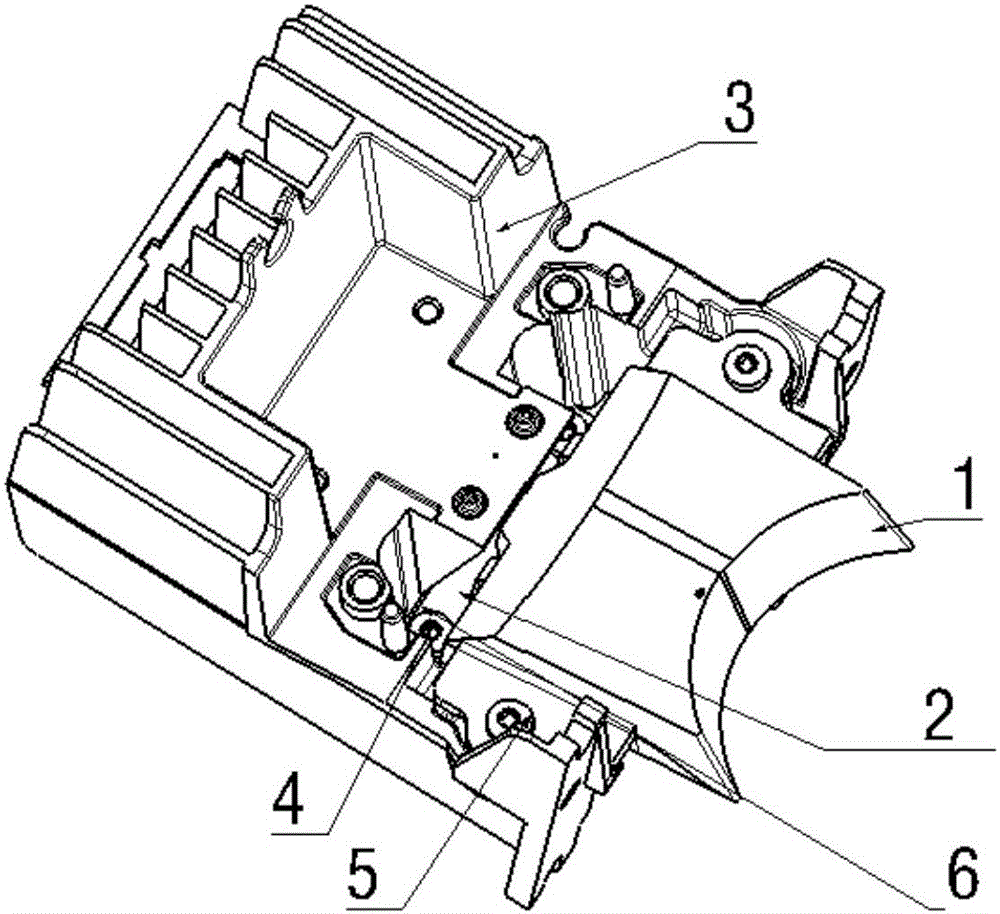

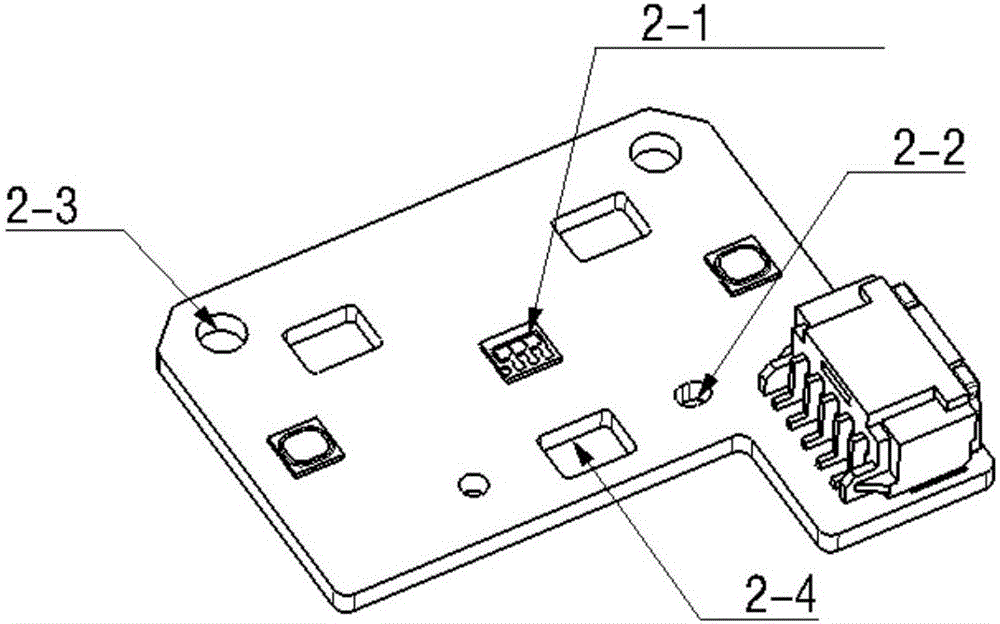

[0073] An optical component positioning system for vehicle lights, comprising: an optical component (1), an LED board (2) and a mounting bracket (3), the LED board (2) is arranged under the optical component (1), and the optical component (1) and The LED board (2) forms a detachable small assembly (7) for installation, which is directly positioned and installed on the installation bracket (3) with the positioning sleeve.

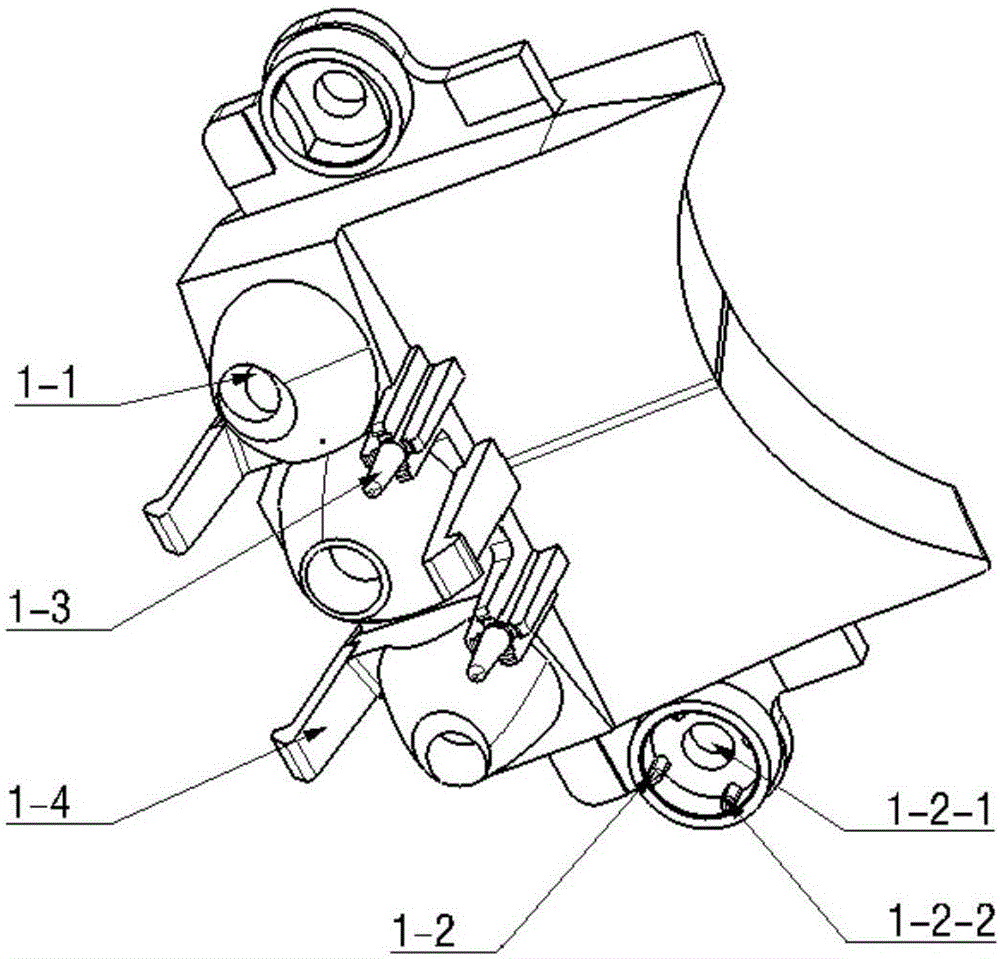

[0074] According to this embodiment, the optical assembly (1) includes a light incident system element (1-1), a positioning sleeve (1-2), a positioning pin (1-3) and a hook (1-4). The positioning sleeve (1-2) is arranged on both sides of the optical assembly (1), and has screw holes (1-2-1) and positioning ribs (1- 2- 2). The detachable small assembly for installation (7) is positioned and installed on the mounting bracket (3) through the positioning ribs (1-2-2), and the positioning pins (1-3) and hooks (1-4) are set on the optical The lower part of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com