Energy gathering ring for gas stove

A technology of energy-gathering rings and gas stoves, applied in the field of gas stoves, can solve the problems of insufficient combustion of gas, easy generation of yellow flames, and lack of passages for air to enter the burner, etc., to achieve simple structure, convenient disassembly and assembly, and promote full combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

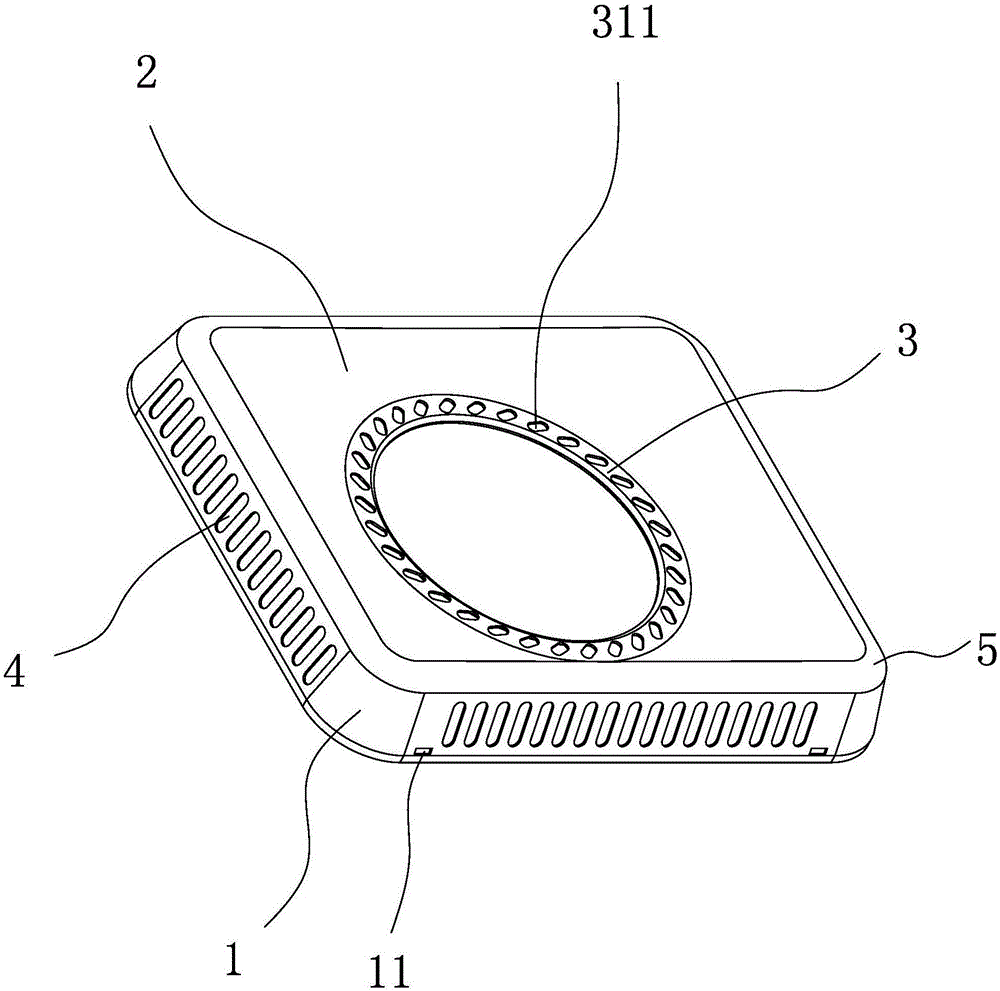

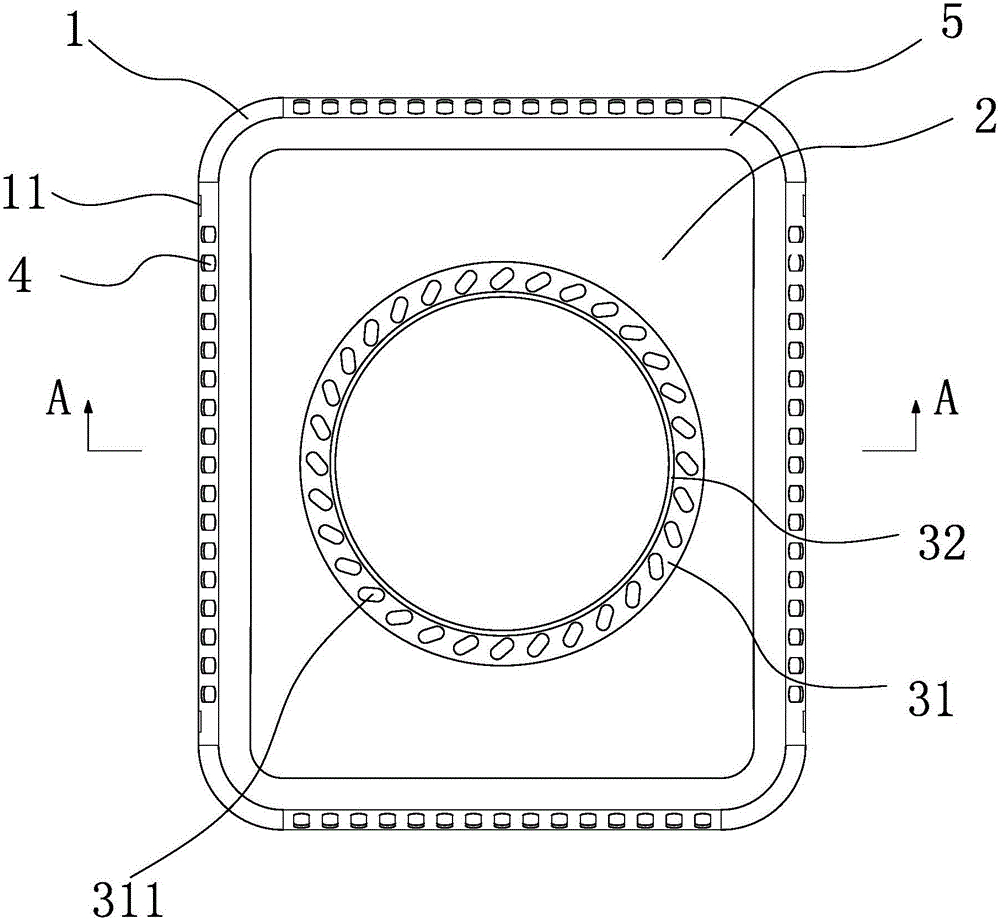

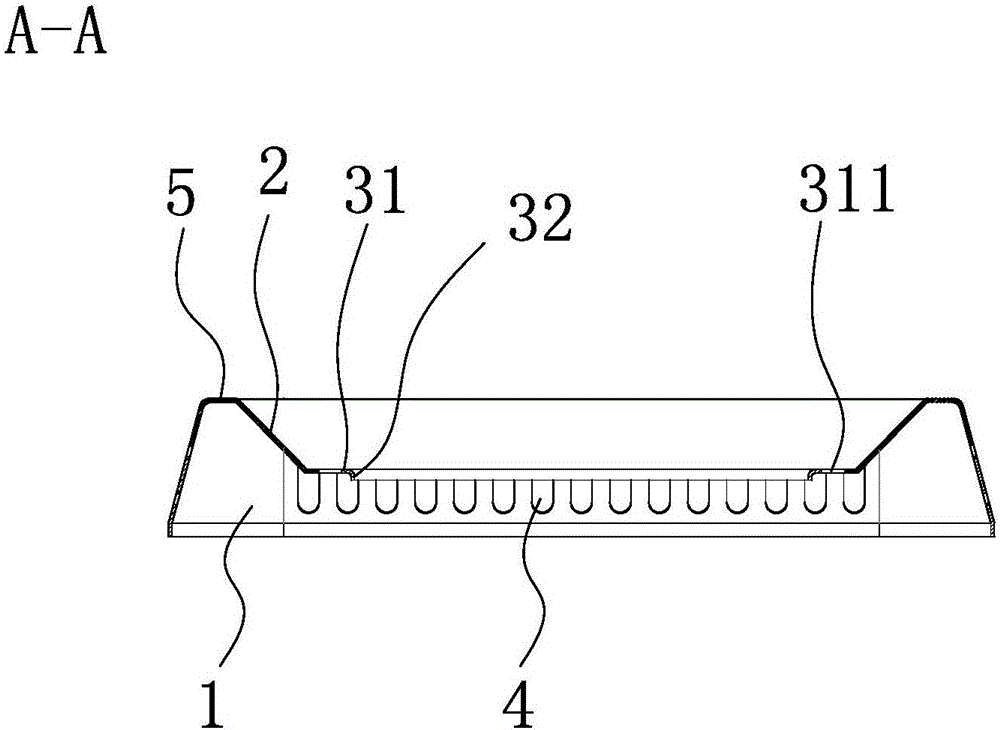

[0027] refer to figure 1 and figure 2 , the first embodiment is an energy-gathering ring for a gas stove, including a support frame ring 1, an energy-gathering portion 2 and a positioning ring portion 3, the support frame ring 1 is rectangular, and the support frame ring 1 has a connection bayonet 11, which is used Placed on the table top of the gas stove and supports the pan support, the positioning ring part 3 is used to be sleeved on the outside of the burner, the energy gathering part 2 is located on the periphery of the positioning ring part 3, and is located inside the support frame ring 1, The energy gathering part 2 is ring-shaped, and the energy gathering part 2 is inclined downward from the outside to the inside, the inner edge of the energy gathering part 2 is connected with the positioning ring part 3, and the outer edge of the energy gathering part 2 is connected with the top end of the support frame ring 1, Moreover, there is a transition ring surface 5 between...

Embodiment 2

[0031] refer to Figure 4 , the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the vent 4 includes a first vent 41 located in front of the support frame ring 1, and a second vent 42 located at the rear of the support frame ring 1 , the third ventilation opening 43 on the left side of the support frame ring 1 and the fourth ventilation opening 44 on the right side of the support frame ring 1, the third ventilation opening 43 and the fourth ventilation opening 44 are all shaped as strip grooves, and the first The third ventilation opening 43 and the fourth ventilation opening 44 are both arranged obliquely relative to the horizontal plane, and the inclination directions of the third ventilation opening 43 and the fourth ventilation opening 44 are opposite.

[0032] Further, the inclination angles of the third vent 43 and the fourth vent 44 in the second embodiment are the same, and the inclination angle β is 60°-8...

Embodiment 3

[0035] refer to Figure 5 , the structure of the third embodiment is basically the same as that of the second embodiment, the difference is that the outer edge of the transition ring surface 5 connected to the support frame ring 1 has a circle of concave annular groove 6, and the annular groove 6 is used to place the pot rack and limit the pot rack. Since the support frame ring 1 is rectangular, the annular groove 6 is rectangular, which can better erect and limit the rectangular pan support, and prevent the pan support from shifting during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com