Ultrasonic method based concrete carbonation depth test method

A technology of carbonization depth and testing methods, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, analysis by making materials undergo chemical reactions, and material analysis by observing the impact on chemical indicators, etc. It can solve the problems of complex test methods, Expensive and other issues, to achieve the effect of simple test methods, integrity assurance, and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for testing the carbonation depth of concrete based on ultrasonic method, comprising the following steps:

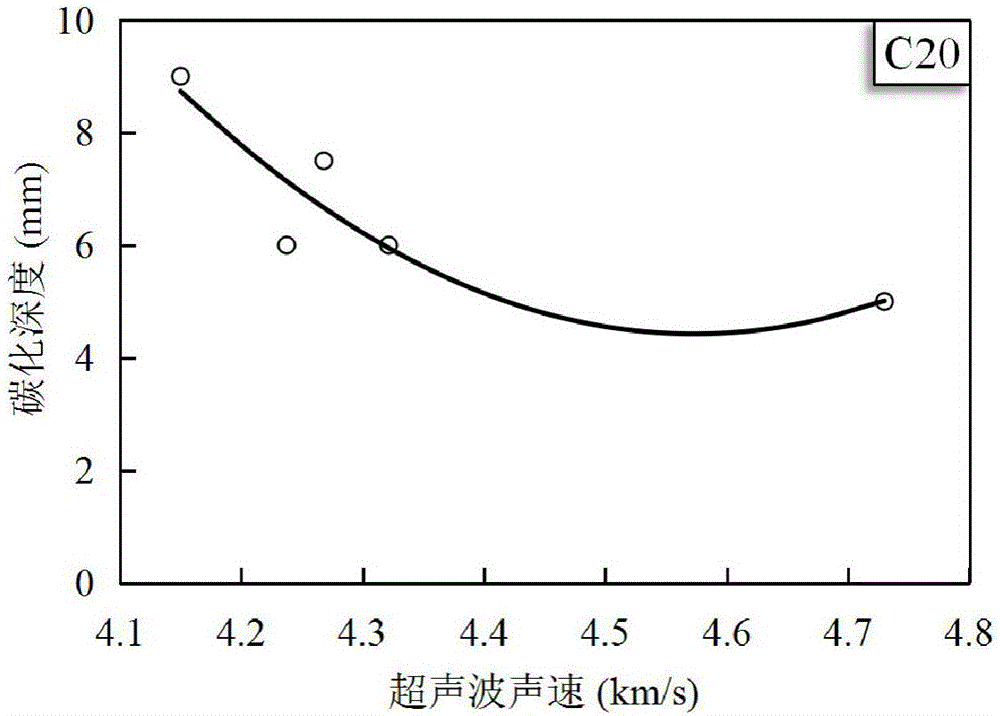

[0038] Step 1, test piece forming and carbonization: form a C20 concrete test piece according to the established mix ratio, remove the formwork, and then perform carbonization for 28 days after curing;

[0039] Step 2, ultrasonic test: After marking the ultrasonic measuring point and measuring the ultrasonic distance, test the time for the ultrasonic wave to pass through the test piece, and calculate the sound velocity value of the test piece;

[0040] Step 3, phenolphthalein indicator test: break the test piece, spray phenolphthalein indicator on the split section, take the average of 10 points as the carbonization depth of the test piece;

[0041] Step 4, by fitting and analyzing the ultrasonic sound velocity value obtained in step (2) and the carbonization depth value obtained in step (3), the relationship between the two is established, such as figur...

Embodiment 2

[0047] A method for testing the carbonation depth of concrete based on ultrasonic method, comprising the following steps:

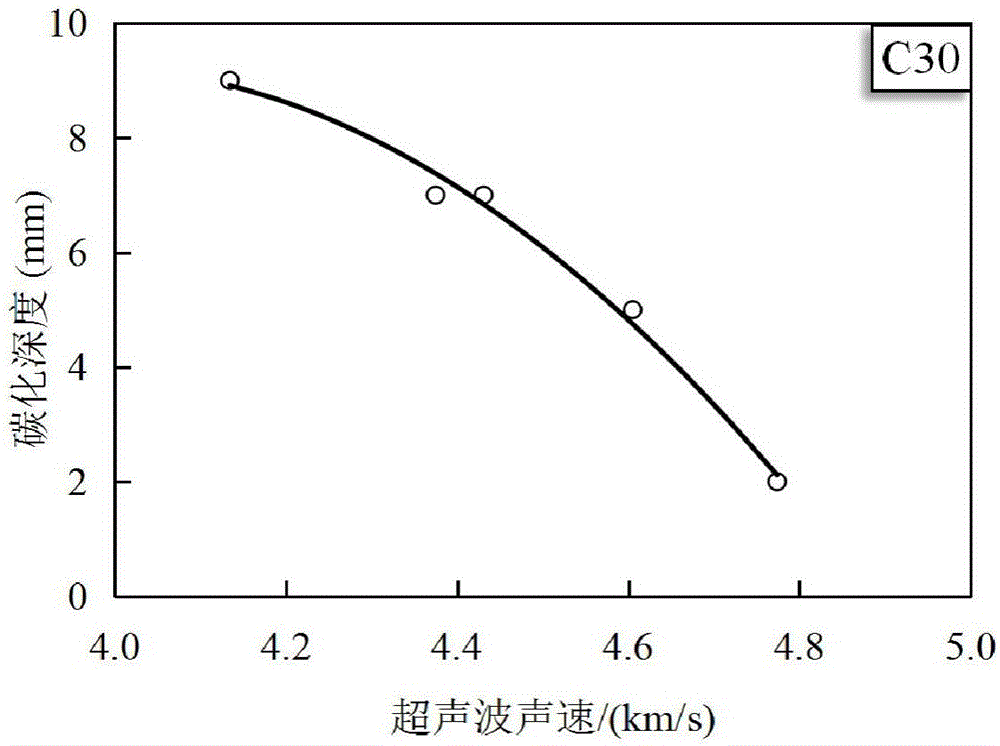

[0048] Step 1, specimen forming and carbonization: form a C30 concrete specimen according to a predetermined mix ratio, remove the formwork, and then perform carbonization for 28 days after curing;

[0049] Step 2, ultrasonic test: After marking the ultrasonic measuring point and measuring the ultrasonic distance, test the time for the ultrasonic wave to pass through the test piece, and calculate the sound velocity value of the test piece;

[0050] Step 3, phenolphthalein indicator test: break the test piece, spray phenolphthalein indicator on the split section, take the average of 10 points as the carbonization depth of the test piece;

[0051] Step 4, by fitting and analyzing the ultrasonic sound velocity value obtained in step (2) and the carbonization depth value obtained in step (3), the relationship between the two is established, such as figure 2...

Embodiment 3

[0057] A method for testing the carbonation depth of concrete based on ultrasonic method, comprising the following steps:

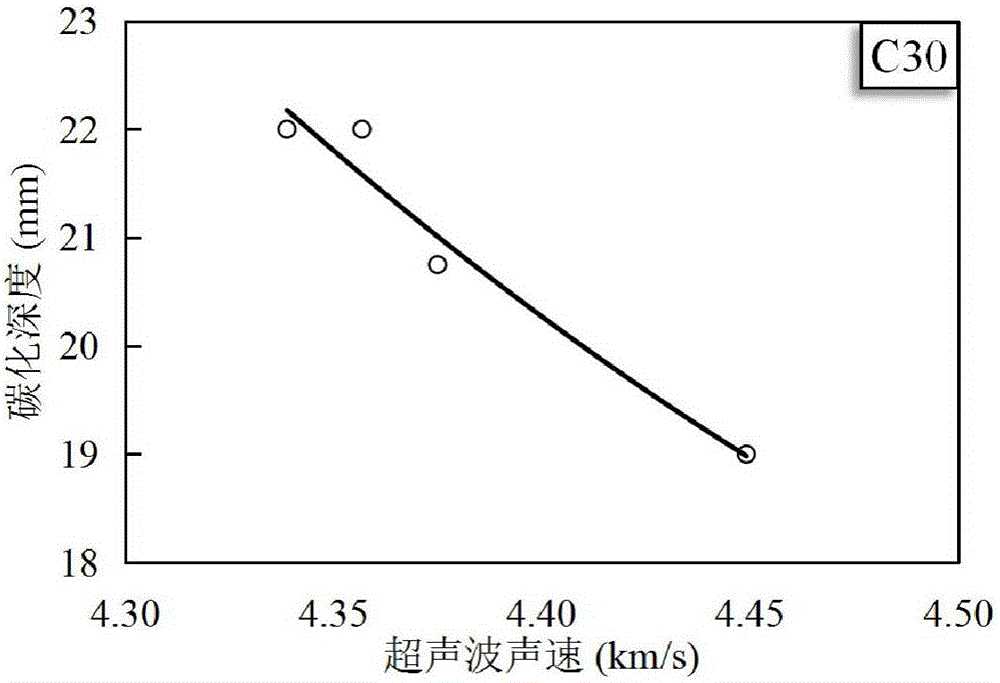

[0058] Step 1, test piece forming and carbonization: Form C30 concrete test pieces mixed with mineral admixtures according to the established mix ratio, and carbonize for 28 days after demoulding and curing;

[0059] Step 2, ultrasonic test: After marking the ultrasonic measuring point and measuring the ultrasonic distance, test the time for the ultrasonic wave to pass through the test piece, and calculate the sound velocity value of the test piece;

[0060] Step 3, phenolphthalein indicator test: break the test piece, spray phenolphthalein indicator on the split section, take the average of 10 points as the carbonization depth of the test piece;

[0061] Step 4, by fitting and analyzing the ultrasonic sound velocity value obtained in step (2) and the carbonization depth value obtained in step (3), the relationship between the two is established, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com