Dedicated load box for electricity consumption inspection

It is a technology of electricity inspection and load box, which is applied in the direction of electrical components, measuring electrical variables, and structural parts of electrical equipment. It can solve problems such as easy accumulation of dust, increased capital expenditure, and reduced heat dissipation effect, so as to ensure heat dissipation effect, Improve heat dissipation efficiency and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

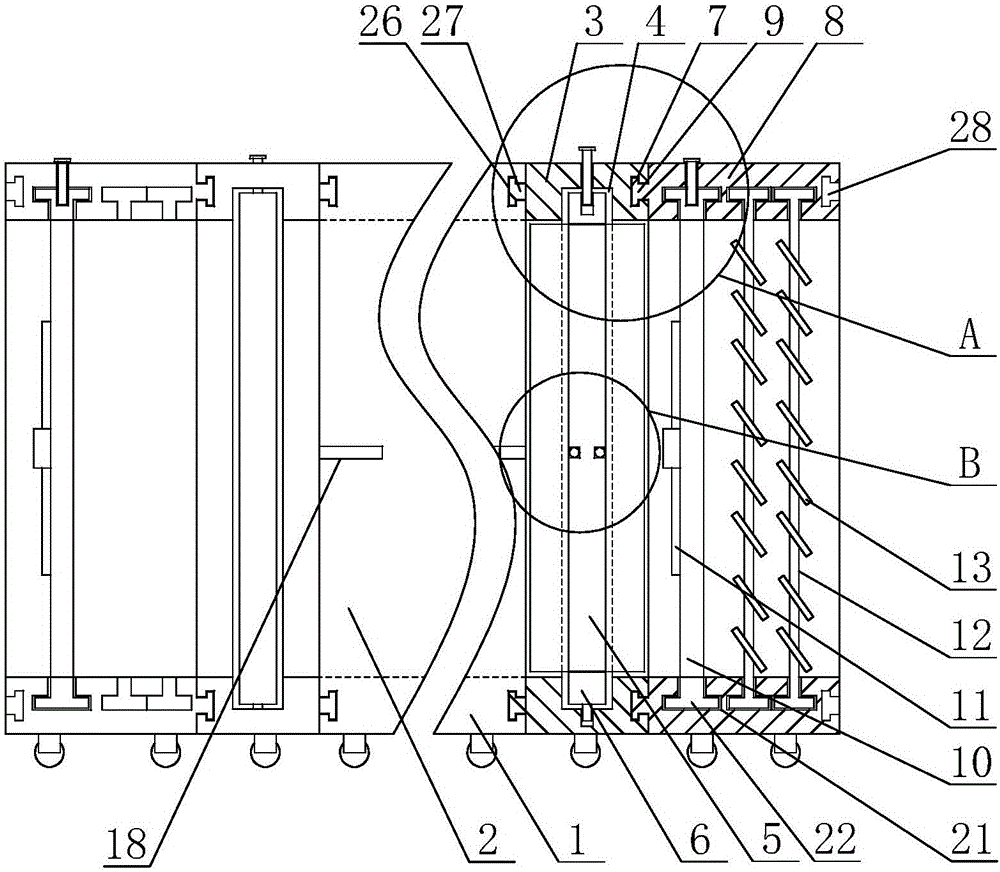

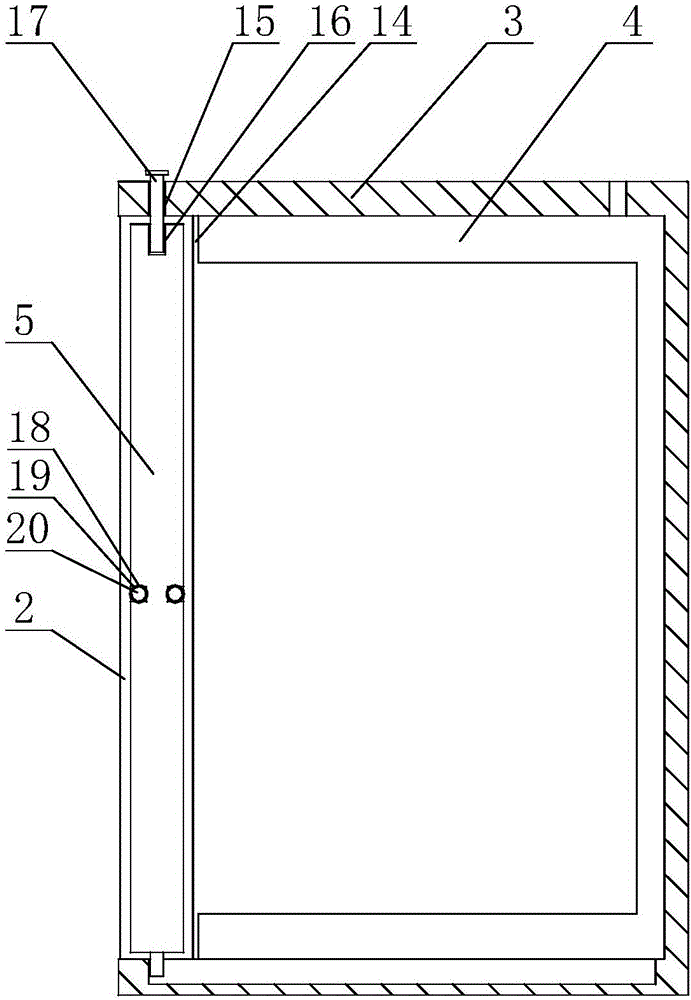

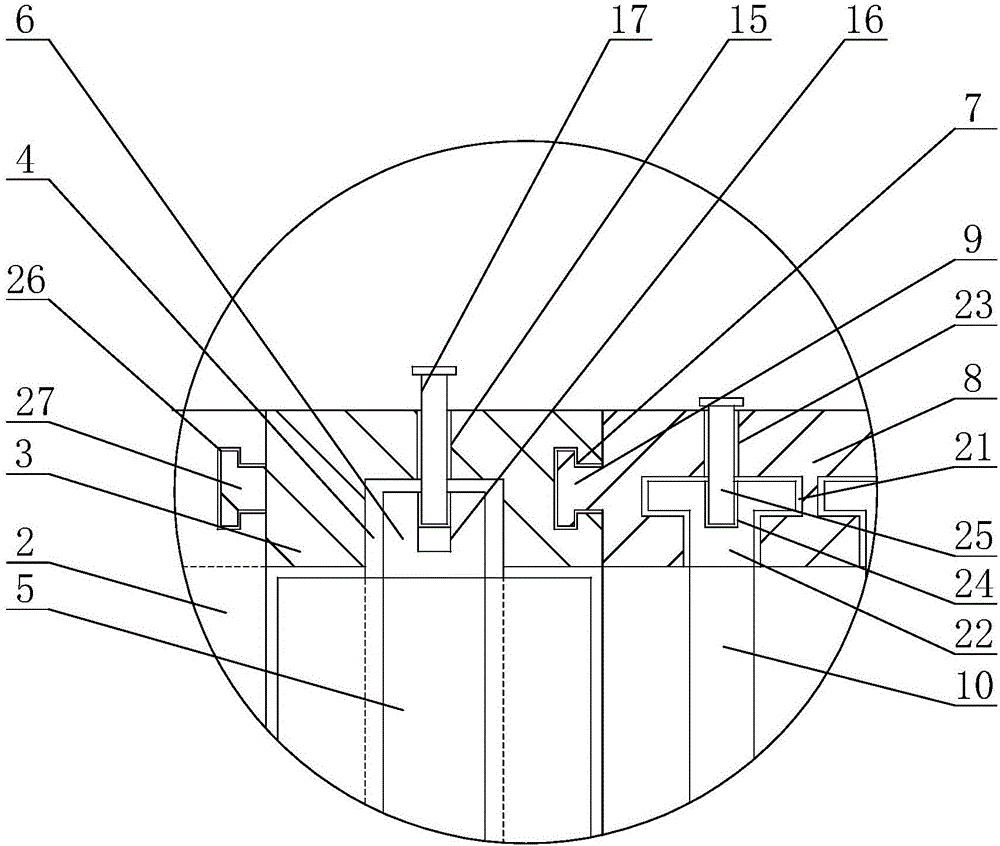

[0044]A special load box for electrical inspection, including a bottom plate 1, on which a U-shaped box body 2 with an opening downward is arranged, which can be realized by welding or bolting, and the bottom plate and the box body can be made of high temperature resistant materials. The cavity formed by the box body 2 and the bottom plate 1 is provided with a resistance element for testing, and the side wall of the box body 2 is provided with an extension hole 18. One end of the box body 2 and the side end of the bottom plate 1 Both are provided with a fourth chute 26, a baffle bracket 3 is provided between the bottom plate 1 and the box body 2, and a fourth slider 27 adapted to the fourth chute 26 is provided on the baffle bracket 3, It can be realized by welding or bolted connection, the baffle bracket 3 can slide along the fourth chute 26, one side of the baffle bracket 3 is provided with an opening, and the horizontal upper horizontal plate of the baffle bracket 3 The bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com