Apparatus for descaling the surface of ingots or rolled products

A sealing surface and pressure chamber technology, applied in workpiece surface treatment equipment, metal rolling, metal rolling, etc., can solve problems such as high axial force, and achieve the effect of improving efficiency and reducing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be explained in detail below by way of example with reference to the figures mentioned.

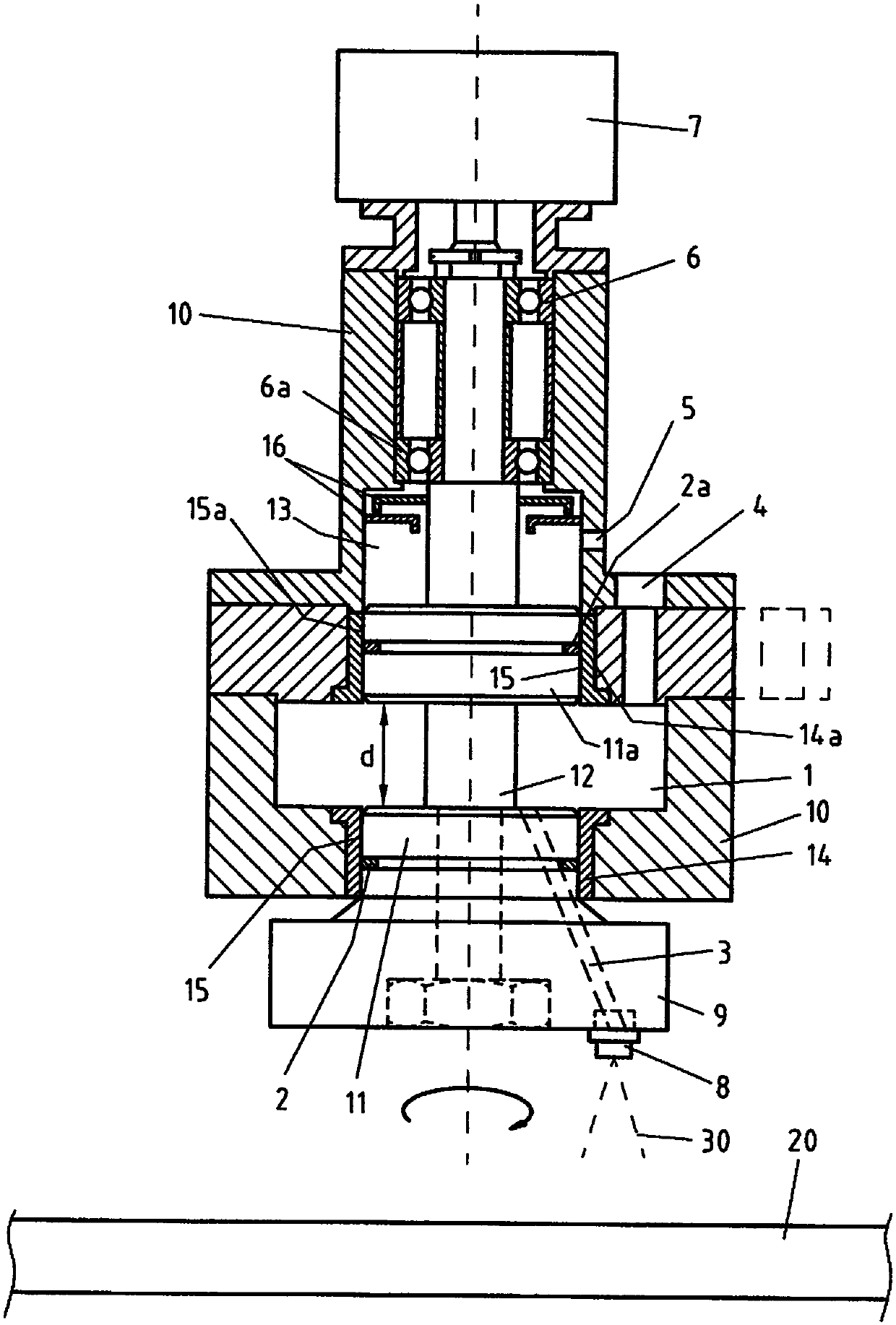

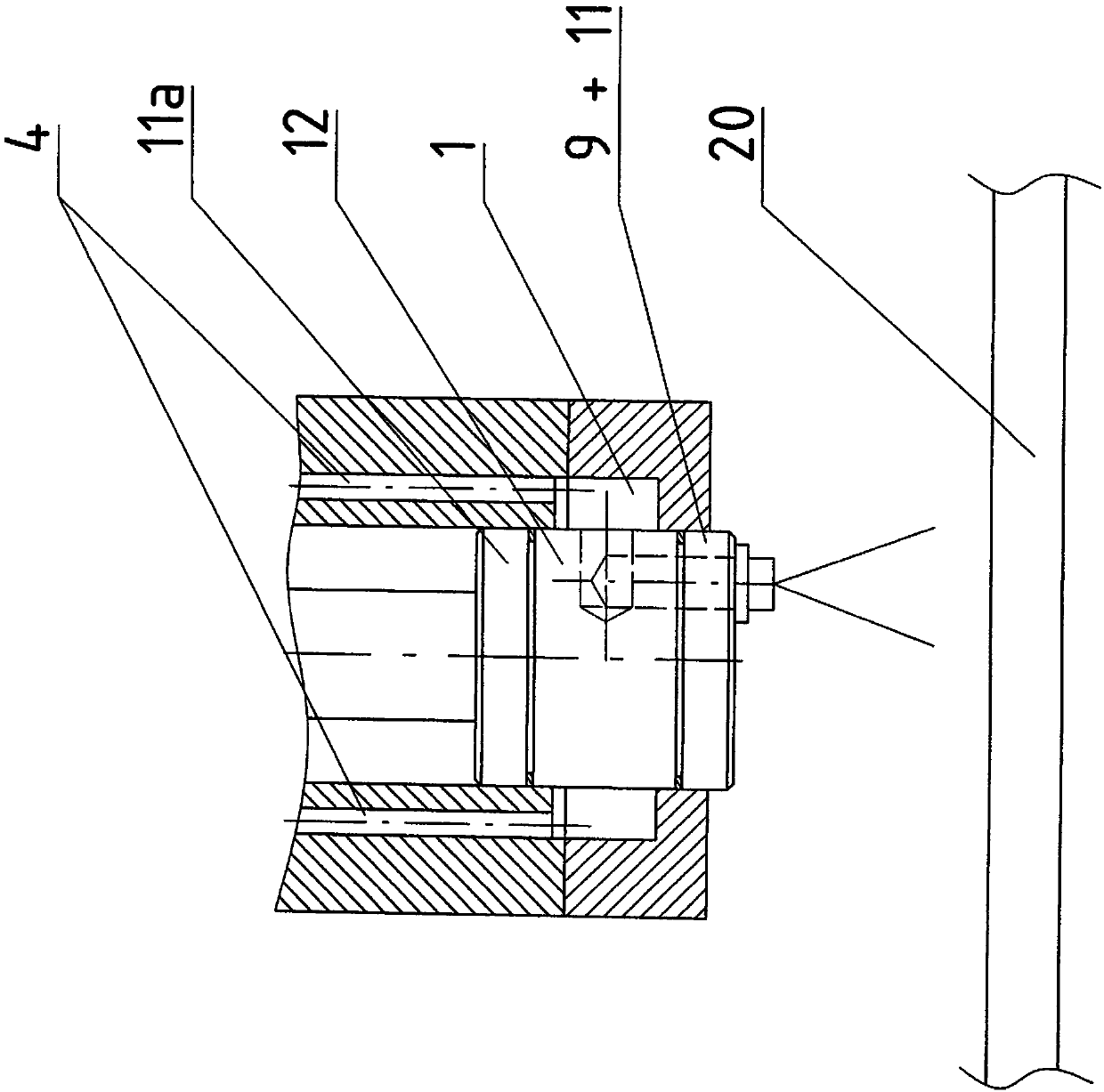

[0022] figure 1 A device according to the invention for cleaning the surface of an object 20 , for example an ingot to be descaled, is shown. The device comprises a housing 10 in which the rotor is mounted via a rotor shaft 12 in bearings 6 , 6 a, which are designed as radial or axial bearings. The first disk 11 and the second disk 11 a each extend radially and are fixed on the rotor shaft 12 at an axial distance d relative to each other. The gap between the first disk and the second disk forms a pressure chamber 1 which can be filled with a pressure medium 30 , for example water, via a supply line 4 . In order to achieve high-pressure cleaning, the pressure medium of the pressure chamber 1 is usually delivered at a high pressure of, for example, 600 bar. The pressure chamber 1 is delimited in the axial direction by two disks 11 , 11 a which are delimited in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com