Overall paddy field ridge profile modeling single-side ridger

A ridge and integral technology, which is applied to the field of work equipment for building paddy field ridges, can solve the problems of no overall profiling, unbalanced power load, and up and down movement of working parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

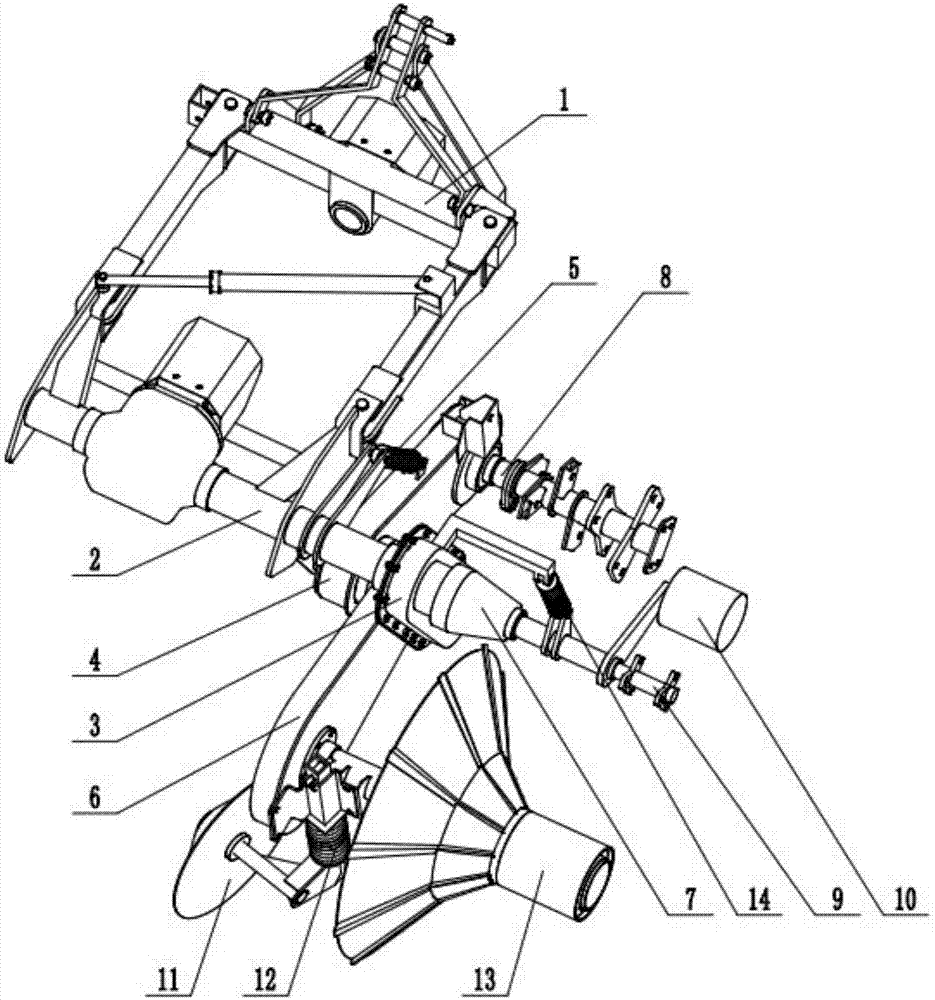

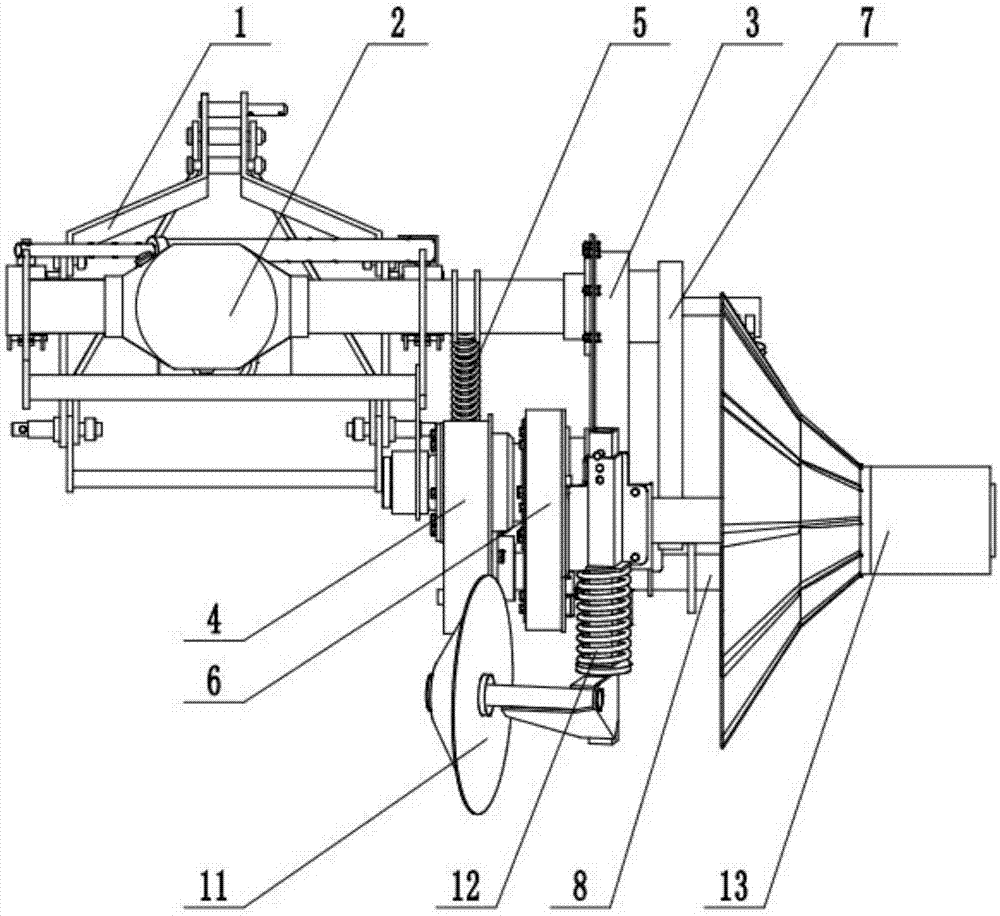

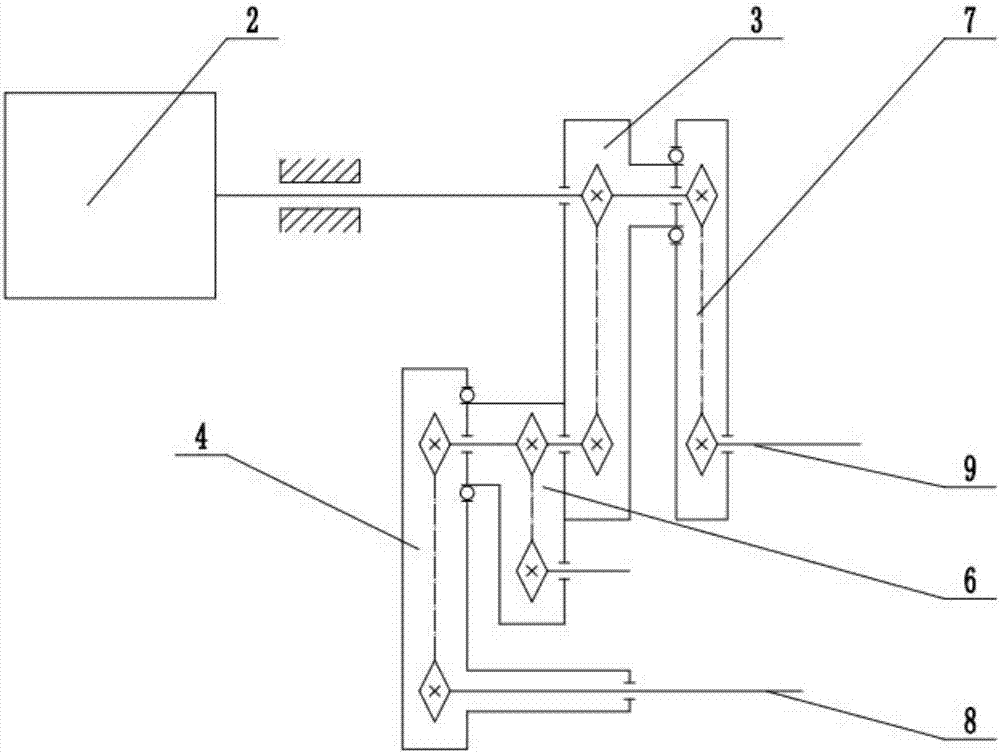

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A paddy field ridge overall profiling single-side ridge building machine includes a frame assembly 1, a main transmission box 2 is installed on the middle part of the rear end of the frame assembly 1, and a power output shaft housing of the main transmission box 2 On the body, the sprocket box A3 is fixed on the outer part of the rear end of the frame assembly 1, the sprocket box C6 is fixed on the sprocket box A3, the sprocket box B4 is rotatably installed on the sprocket box C6, and the chain The wheel box D7 is rotatably installed on the outer side of the sprocket box A3, the main transmission box 2 is connected with the sprocket box A3 and the sprocket box D7 in turn, and the sprocket box A3 is connected with the sprocket box C6 and the sprocket box in turn Connect box B4, connect and install the lower rotary tiller shaft assembly 8 on the power outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com